Слайд 2

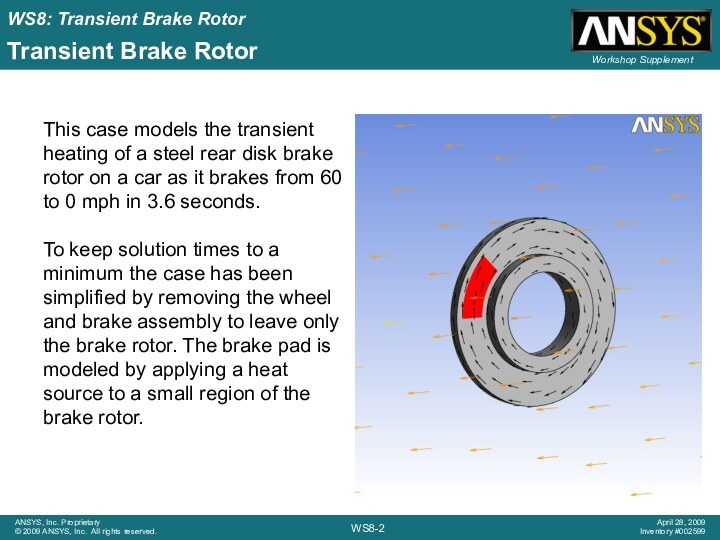

Transient Brake Rotor

This case models the transient heating

of a steel rear disk brake rotor on a

car as it brakes from 60 to 0 mph in 3.6 seconds.

To keep solution times to a minimum the case has been simplified by removing the wheel and brake assembly to leave only the brake rotor. The brake pad is modeled by applying a heat source to a small region of the brake rotor.

Слайд 3

Assumptions

The ambient air temperature is 81 F and

the rotor is at ambient temperature before braking begins

The

vehicle tire size is 205/55/R16

The total vehicle weight including passengers and cargo is 1609 kg

The entire kinetic energy of the vehicle is dissipated through the brake rotors

Energy dissipation during braking is split 70/30 between the front and rear brakes and split evenly between the left and right sides

The vehicles speed reduces linearly from 60 to 0 mph in 3.6 seconds

Слайд 4

Solution Approach

The solution is transient, so you will

need to begin by solving a steady-state case at

a vehicle speed of 60 mph

You will need two domains; a solid domain for the brake rotor and a fluid domain for the surrounding air

The reference frame will be that of the vehicle. So the rotor will be spinning relative to this reference frame and air will be flowing past at the vehicle velocity

Слайд 5

Start Steady-State Simulation

Start CFX-Pre in a new working

directory and create a new simulation named BrakeDisk

Right-click on

Mesh in the Outline tree and import the CFX-Mesh file named BrakeRotor.gtm

The rotor mesh will be imported along with a bounding box surrounding the rotor

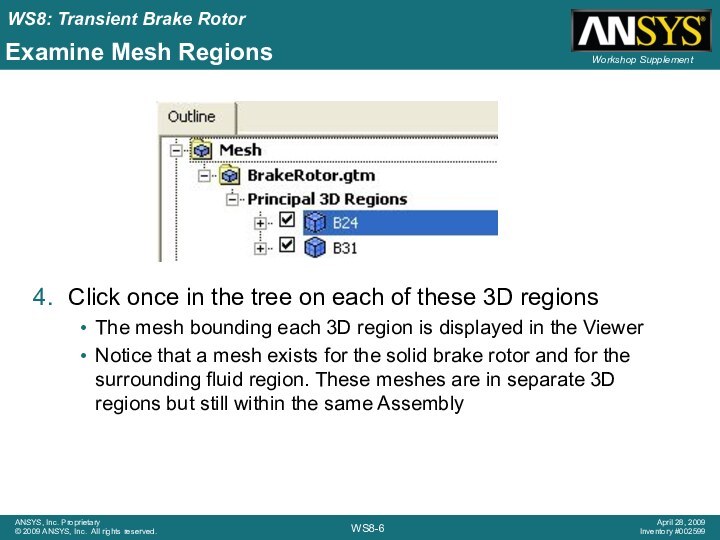

In the Outline tree, expand Mesh > BrakeRotor.gtm > Principal 3D Regions

There are two 3D regions in this mesh named B24 and B31

Слайд 6

Examine Mesh Regions

Click once in the tree on

each of these 3D regions

The mesh bounding each 3D

region is displayed in the Viewer

Notice that a mesh exists for the solid brake rotor and for the surrounding fluid region. These meshes are in separate 3D regions but still within the same Assembly

Слайд 7

Create the Fluid Domain

Select the Domain icon from

the toolbar and enter

the Name as AirDomain

Pick the Location corresponding to the air region from the drop-down menu

The regions are highlighted in the Viewer to assist you

The fluid domain uses Air Ideal Gas as the working fluid at a Reference Pressure of 1 [atm]; the domain is Stationary relative to the chosen reference frame and Buoyancy (gravity) can be neglected. Use this information to set appropriate Basic Settings for this domain

By default the Simulation Type is set to Steady-State, so the next step is to create the fluid domain

Слайд 8

Create the Fluid Domain

Switch to the Fluid Models

tab for the domain

Set the Heat Transfer Option to

Thermal Energy and leave the Turbulence Option set to the default k-Epsilon model

Switch to the Initialisation tab for the domain

Слайд 9

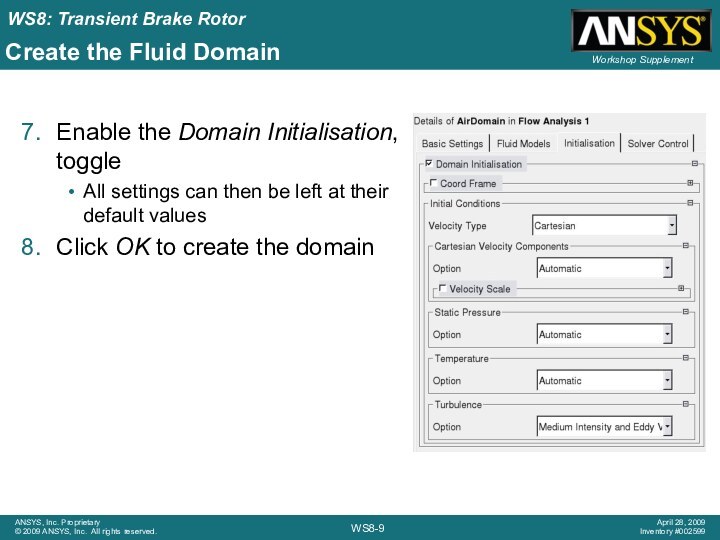

Create the Fluid Domain

Enable the Domain Initialisation, toggle

All

settings can then be left at their default values

Click

OK to create the domain

Слайд 10

Create the Solid Domain

Create a new domain named

Rotor

Pick the Location corresponding to the brake rotor

Set the

Domain Type to Solid Domain

Set the Material to Steel

Leave the Domain Motion Option as Stationary

Switch to the Solid Models tab and enable the Solid Motion toggle

The next step is to create the solid domain for the brake rotor.

Слайд 11

Create Expressions

Switch to the Outline tab (do not

close the Domain tab)

Right-click on Expressions in the tree

and select Insert > Expression

You may need to expand the Expressions, Functions and Variables entry in the tree to be able to right-click on Expressions

Enter the expression Name as Speed and click OK

The Expressions tab will appear

The next quantity to enter is the Angular Velocity. This needs to be calculated based on the vehicle speed (60 mph) and the radius of the tire attached to the brake rotor. The tires were specified as 205/55/R16 (205 mm tire width, aspect ratio of 55, 16” rim diameter). Next you will create expressions to calculate the Angular Velocity.

Set the Solid Motion Option to Rotating

Слайд 12

Create Expressions

In the Definition window (bottom-left of the

screen) enter

60 [mile hr^-1] then click Apply

Right-click

in the top half of the Expressions window and select Insert > Expression; enter the Name as TireRadius

Enter the Definition as (16 [in] / 2) + (205 [mm] * 0.55) and click Apply

Create another expression named Omega, type the Definition as Speed / TireRadius and then click Apply

Now switch back to the Domain: Rotor tab

Слайд 13

Complete the Solid Domain

Click the expression icon next

to the Angular Velocity field and type in Omega

(the name of the expression you just created)

Pick the Rotation Axis as the Global X axis

On the Initialisation tab set the Temperature Option to Automatic with Value and enter a Temperature of 81 [ F ]

Make sure you have changed the units to F

Now click OK to create the domain

Слайд 14

Create Boundary Conditions

In the Outline tree, right-click on

AirDomain and select Insert > Boundary. Enter the Name

as AirIn when prompted and click OK

On the Basic Settings tab, set the Boundary Type to Inlet and the Location to Inlet

On the Boundary Details tab, set the Mass And Momentum Option to Normal Speed

In the Normal Speed field click the expression icon and enter Speed

This is one of the expressions you created earlier

Boundary conditions are needed for the bounding box of the air domain. You will create an inlet boundary upstream of the rotor, an outlet boundary downstream of the rotor and an opening boundary for the remaining bounding surfaces. Start with the inlet boundary:

Слайд 15

Create Boundary Conditions

Set the Heat Transfer Option to

Static Temperature and enter the a value of 81

[ F ]

Click OK to create the inlet boundary

Right-click on AirDomain and insert a boundary named AirOut

Use the following setting for this boundary:

Boundary Type = Outlet

Location = Outlet

Mass And Momentum Option = Average Static Pressure

Relative Pressure = 0 [ Pa ]

Click OK to create the outlet boundary

Now create the outlet boundary condition:

Слайд 16

Create Boundary Conditions

Insert a boundary named AirOpening into

the AirDomain

Use the following settings for this boundary:

Boundary Type

= Opening

Location = OuterWalls

Mass And Momentum Option = Entrainment

Relative Pressure = 0 [ Pa ]

Turbulence Option = Zero Gradient

Heat Transfer Option = Opening Temperature

Opening Temperature = 81 [ F ]

Click OK to create the opening boundary

Lastly, create the opening boundary condition:

Слайд 17

Create Domain Interface

Select the Domain Interface icon from

the toolbar and enter

the Name as RotorInterface

Set the Interface Type to Fluid Solid

For Interface Side 1, set the Domain (Filter) to AirDomain; pick both BrakePadsFluidSide and RotorFluidSide from the Region List

Domain Interfaces are required when more than one domain exists in your simulation. Without domain interfaces one domain would not see or feel the effect of neighboring domains. A Default Fluid Solid Interface should already exist, but we will manually create the interface here as a practice exercise.

Слайд 18

Create Domain Interfaces

For Interface Side 2, set the

Domain (Filter) to Rotor. Pick BrakePadsSolidSide and RotorSolidSide from

the Region List

Under Interface Models, leave the Frame Change and Pitch Change Option set to None

Click OK to create the Domain Interface

Notice that the default interface no longer exists

Слайд 19

Modify Interface Boundaries

Double click RotorInterface Side 1 in

the AirDomain

Select the Boundary Details tab

Notice in the Outline

tree that new Side 1 and Side 2 boundary conditions have been created automatically in the Air and Solid domains. These boundary conditions are associated with the Domain Interface

By default the boundary condition is a no slip, stationary, smooth wall. It is necessary to modify these settings so that the air feels a rotating wall at the fluid solid interface

Слайд 20

Modify Interface Boundaries

Enable the Wall Velocity toggle

Set the

Option to Rotating Wall

Set the Angular Velocity to the

expression Omega

Pick Global X as the Rotation Axis

Click OK

Слайд 21

Set Solver Controls

Double-click the Solver Control entry in

the Outline tree

Change the Fluid Timescale Control to Physical

Timescale

Based on the domain length (about 1.2 [m]) and the inlet velocity (60 mph), the advection time for air through the domain is about 0.045 [s]

Set the Physical Timescale to 0.02 [s]

Set the Solid Timescale Control to Physical Timescale

Set the Solid Timescale to 100 [s]

Click OK

The last step before running the steady-state solution is to set the Solver Control parameters. Default Solver Control parameters already exist, so you can edit the existing object:

Слайд 22

Run the Steady-State Solution

Select the Run Solver and

Monitor icon

Click Save to write the BrakeDisk.def file and

launch the Solver Manager

The solution should converge in about 60 iterations

When the Solver finishes, check the Domain Imbalance values in the out file

All imbalances should be well below 1%

Click the Post Process Results icon from the toolbar

You can now run the case in the Solver

Слайд 23

Post-Processing

Check that the solution looks correct by plotting

velocity

On the Variables tab, double click on the Temperature

variable. Check that the Min and Max values are almost identical

Quit CFX-Post and return to the BrakeDisk simulation in CFX-Pre

Save the CFX-Pre simulation

Since this case is just the starting point for the transient simulation, there is very little post-processing to perform.

Слайд 24

Start Transient Simulation

Select File > Save Case As…

Enter

the File name as BrakeDiskTrn.cfx and click Save

To set

up the transient simulation you will need to:

Edit the expression for Speed so that the inlet velocity reduces with time

Change the Simulation Type to Transient and enter the transient time step information

Add a heat source to the braking surfaces to simulate the heat generated through braking. You’ll need additional expressions for this

Modify the Solver Controls

Add some Monitor Points

Next you will define the transient simulation by modifying the steady-state simulation in CFX-Pre. Start by saving the simulation under a new name so that you do not overwrite the previous set up

Слайд 25

Edit Expressions

Right-click on Expressions in the Outline tree,

select Insert > Expression and enter the name as

StoppingTime

Set the Definition to 3.6 [s] and click Apply

Change the expression Speed to:

60 [mile hr^-1] – (60 [mile hr^-1] / StoppingTime)* t

then click Apply

On the Plot tab, check the box for t and enter a range from 0 – 3.6 [s]

Click Plot Expression

You should see Speed decreasing linearly from about 27 to 0 [m s^-1] as shown on the next slide

Start by defining the stopping time for the vehicle and then editing the expression for Speed based on the stopping time

Слайд 26

Edit Expressions

Create a new expression named Deltat with

a value of 0.05 [s]

This expression will be used

next to set the timestep size for the transient simulation

Слайд 27

Change Simulation Type

In the Outline tree, double click

on Analysis Type

Set the Analysis Type Option to Transient

Enter

the Total Time as the expression StoppingTime

Enter Timesteps as the expression Deltat

Set the Initial Time Option to Automatic with Value and use a Time of 0 [s]

Transient timesteps of 0.05 [s] will be taken, starting at 0 [s] and ending at 3.6 [s] for a total of 72 timesteps

Click OK

Next you will change the Simulation Type to Transient and enter information about the duration of the simulation

Слайд 28

Add a Braking Heat Source

Edit the RotorInterface Side

2 boundary condition in the Rotor domain

On the Sources

tab enable the Boundary Source toggle, then the Source toggle and then the Energy toggle

To add a heat source to simulate the heat generated through braking, edit the solid side boundary condition associated with the interface RotorInterface. Notice that the interface covers the entire surface of the rotor, but a mesh region exists where the brake pads are located. In the Outline tree you can expand Mesh > BrakeRotor.gtm > Principle 3D Regions > B31 > Principle 2D Regions to see the region BrakePadsSolidSide.

Слайд 29

Add a Braking Heat Source

Switch to the Expressions

tab, or double click Expressions from the Outline tree

if the tab is not already open

Create a new expression named Mass with a value of 1609 [kg] and click Apply

To calculate the kinetic energy lost over one timestep you need to know the change in Speed over the timestep. You already have an expression for the Speed at the end of the timestep, so you need an expression for the Speed at the end of the previous timestep.

Using the assumptions listed at the start of the workshop, the energy to apply to the brake surface can be calculated. The vehicle velocity as a function of time and the vehicle mass is known. Therefore the kinetic energy dissipated through the brakes over one timestep can be calculated. It is also known that 15% of the total energy is dissipated through each rear brake rotor.

Слайд 30

Add a Braking Heat Source

Right click on the

expression named Speed and select Duplicate… from the pop-up

menu

Copy of Speed will be created

Right click on Copy and Speed and Rename it to SpeedOld

Edit the Definition for SpeedOld to read:

60 [mile hr^-1] – (60 [mile hr^-1] / StoppingTime)* (t – Deltat)

Create a new expression named DeltaKE. Enter the Definition as: 0.5 * Mass * (SpeedOld^2 – Speed^2)

15% of DeltaKE will be applied to the rotor. The energy source term will be applied as a flux which has units of [J s^-1 m^-2]. Therefore you need to divide by the timestep size and the area of the brake pads to obtain the correct flux. Lastly, the source needs to be limited to just the brake pad region within the RotorInterface Side 2 boundary condition.

Слайд 31

Add a Braking Heat Source

Create a new expression

named HeatFlux. Enter the Definition as:

inside()@REGION:BrakePadsSolidSide * 0.15 *

DeltaKE / ( area()@ REGION:BrakePadsSolidSide * Deltat )

Switch back to the Boundary tab for RotorInterface Side 2

Set the Energy Option to Flux

Enter the expression HeatFlux for the Flux and click OK

Слайд 32

Modify Solver Controls

Edit the Solver Control object from

the Outline tree

The default settings are appropriate for this

simulation. Click OK

The default transient Solver Control settings use a maximum of 10 coefficient loops per timestep with a RMS residual target of 1e-4. Fewer loops may be used if the residual target is met sooner. If the residual target is not met after 10 loops the solver will continue on to the next timestep regardless. It is therefore important to check you are converging to an acceptable level during a transient simulation.

Слайд 33

Monitor Points

Edit the Output Control object from the

Outline tree

On the Monitor tab enable the Monitor Options

check box

In the Monitor Points and Expressions frame, click the New icon to create a new monitor point

Enter the Name as AvgRotorT and click OK

Monitor Points are used to monitor variables at x, y, z coordinates or monitor the value of expressions as the solution progresses.

Слайд 34

Monitor Points

Change the Option to Expression

Enter the Expression

Value as volumeAve(Temperature)@Rotor

This expression will return the average temperature

of the rotor

Click the New icon to create a second monitor point named BrakeSfcT.

Make sure that BrakeSfcT is selected, change the Option to Expression and enter the expression below. You can right click on the Expression Value field instead of typing. areaAve(Temperature)@REGION:BrakePadsSolidSide

This expression will return the average temperature on the specified region

Click Apply to commit the Output Control settings

Слайд 35

Transient Results

Switch to the Trn Results tab in

the Output Control window and click the Create New

icon

Change the Option to Selected Variables

By selecting only the variables of interest the transient results files are kept small

In the Output Variables List, use the … icon to select the variables Temperature and Velocity (use the Ctrl key to pick multiple variables)

Set the Output Frequency Option to Timestep Interval

Enter a Timestep Interval of 4 then click OK

By default results are only written at the end of the simulation. You need to create transient results files to be able to view the results at different time intervals.

Слайд 36

Start Solver

Click the Define Run icon from the

toolbar

This will launch the Solver Manager but will not

start the run. We need to provide an Initial Values File before running the Solver

Click Save to write the file BrakeDiskTrn.def

A Physics Validation Summary will appear

Read the Physics Validation message and then read the warning it is referring to which is shown in the message window below the Viewer. Click Yes to continue.

When the Solver Manager opens enable the Initial Values Specification toggle and select the file BrakeDisk_001.res. Click Start Run.

The transient simulation is now ready to proceed to the solver.

Слайд 37

Monitor Completed Run

Click the Stop icon in the

Solver Manager after a couple of timesteps have been

completed

In the Solver Manager select File > Monitor Finished Run

Browse to the directory where the previously run transient files are located, select the .res file then click Open

On the User Points tab the time history plots for the two monitor points are shown.

Check that the residual plots and imbalances show reasonable convergence

Click the Post-Process Results icon to proceed to CFX-Post

The solution time for the transient simulation is significantly more than for the steady-state simulation. Results files are provided for the transient simulation to save time.

Слайд 38

Post Processing

Edit the RotorInterface Side 2 object

Colour the

object by Temperature using a Global Range

Edit the Default

Legend View 1 object

On the Appearance tab, change the Precision to 0 and Fixed (the default is 3 and Scientific) and then click Apply

Orient the view similar to the image below

Next you will make a transient animation showing the evolution of temperature on the surface of the rotor.

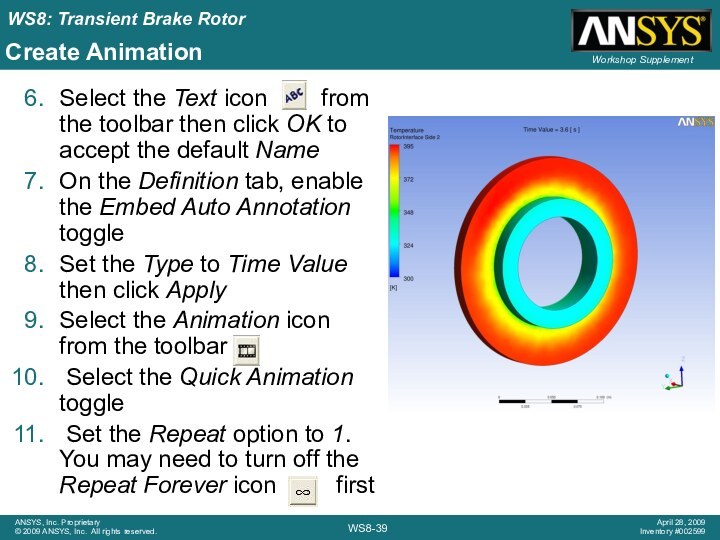

Слайд 39

Create Animation

Select the Text icon

from the toolbar then click OK to accept the

default Name

On the Definition tab, enable the Embed Auto Annotation toggle

Set the Type to Time Value then click Apply

Select the Animation icon from the toolbar

Select the Quick Animation toggle

Set the Repeat option to 1. You may need to turn off the Repeat Forever icon first

Слайд 40

Create Animation

Enable the Save Movie toggle

Check that

Timesteps is highlighted in the selection window and click

the Play icon to play and generate the animation

CFX-Post will generate one frame from each of the available transient results files. The animation file will be written to the current working directory.

Слайд 41

Rotating Solid Domains Notes

The following notes are for

reference only and explain some of the features of

rotating solid domains in greater depth.

In a solid domain both the Domain Motion and the Solid Motion can be set to Rotating. Setting the Domain Motion Option to Rotating for a solid domain in a transient simulation automatically includes the circumferential position for the solid domain in the results file. In other words, the solid domain will appear to rotate in the theta direction for visualisation purposes.

By itself, using Domain Motion = Rotating tells the solver to use mesh coordinates in the relative frame, similar to rotating fluid domains. It does not cause the solver to physically rotate the volumetric mesh or temperature field during the solution. Therefore the solution will look identical to that of a stationary solid domain.

Слайд 42

Rotating Solid Domains Notes

The reason for this behavior

is not immediately obvious. However, there are many rotating

solid cases that can be modeled as stationary solids, but for post-processing purposes you still want to see the solid rotate along with, say, the fluid domains to which it is connected. Turbomachinery blade cooling applications are a common example.

In some cases is it also necessary to account for the rotational motion of the solid energy, and the resulting temperature field. One of two approaches can be used to account for this effect, and the two are not exactly equivalent. Fortunately there is some flexibility in your choice of approach. Either approach is valid when you want energy to be distributed in the circumferential direction around the solid and the source of heat is stationary in the stationary frame.

Слайд 43

Rotating Solid Domains Notes

The first approach, as used

in this workshop, is to use the Solid Motion

settings on the Domain > Solid Models panel. The solid mesh is not physically rotated; instead a term is added to the solid energy equation to advect the energy using the defined velocity components or angular velocity. Therefore a stationary heat source applied to a solid boundary condition, like the brake pad for example, is felt throughout the entire disc rotor. Remember that we are in a stationary reference frame here, so the heat source applied to the boundary does not rotate.

The second approach is to account for the relative rotational motion at the Fluid-Solid interface using a rotating reference frame for the solid (Domain Motion Option = Rotating) combined with the Transient Rotor Stator (TRS) frame change model, leaving the Solid Motion undefined. The relative motion at the interface is accounted for by rotating the surface mesh at the interface. This modeling approach is appropriate in two situations: when the heat source is applied from the fluid side of the interface or when the heat source is applied from the solid side and the heat source rotates with the solid.

Слайд 44

Rotating Solid Domains Notes

As an example, if a

hot jet of fluid is impinging on a cooler

rotating solid, the entire rotating solid will heat up over time. If you do not use one of these two approaches then a single hot spot will form in the solid domain. In the first approach the Domain Motion is left as Stationary while the Solid Motion settings define the motion. The frame change model at the interface is left as None or Frozen Rotor. In the second approach there is no advection term in the solid energy equation (Solid Motion is not defined), but the mesh rotates at the interface (Domain Motion is Rotating and a TRS interface is used).

Note that in general you should not combine the two approaches. You would not use Domain Motion with Transient Rotor Stator and also define Solid Motion since this will rotate things twice.

Слайд 45

Rotating Solid Domains Notes

At the Fluid-Solid interface, Frame

Change and Pitch Change options must be set. You

should understand these concepts for Fluid-Fluid interfaces before understanding the following guidelines. The Fluid-Solid interface Pitch Change model can be None, Automatic, Pitch Ratio or Specified Pitch Angles. When the full 360 degree solid domain in modeled, as in this workshop, then None, Pitch Ratio of 1.0 and Specified Pitch Angles of 360 degrees on both sides are all equivalent options.

If you are modeling a periodic section of the fluid and solid domain, and a pitch change occurs at the interface, then you should use one of Automatic, Pitch Ratio or Specified Pitch Angle to correctly scale the heat flow profile across the interface, with the local magnitude scaled by the pitch ratio. In this case side 1 and side 2 heat flows should differ by the pitch ratio.