Слайд 2

In-Line Aircraft Engines

This type of engine has cylinders

lined up in one row. It typically has an

even number of cylinders, but there are instances of three- and five cylinder engines. The biggest advantage of an inline engine is that it allows the aircraft to be designed with a narrow frontal area for low drag. The disadvantages of an inline engine include a poor power-to-weight ratio, because the crankcase and crankshaft are long and thus heavy. If the engine crankshaft is located above the cylinders, it is called an inverted inline engine, which allows the propeller to be mounted up high for ground clearance even with short landing gear. An in-line engine may be either air cooled or liquid cooled, but liquid-cooling is more common because it is difficult to get enough air-flow to cool the rear cylinders directly.

Слайд 4

Rotary Engines

Rotary engines have all the cylinders in

a circle around the crankcase like a radial engine

(see below), but the difference is that the crankshaft is bolted to the airframe, and the propeller is bolted to the engine case. The entire engine rotates with the propeller, providing plenty of airflow for cooling regardless of the aircraft's forward speed. Some of these engines were a two-stroke design, giving them a high specific power and power-to-weight ratio. Unfortunately, the severe gyroscopic effects from the heavy rotating engine made the aircraft very difficult to fly. The engines also consumed large amounts of castor oil, spreading it all over the airframe and creating fumes which were nauseating to the pilots. Engine designers had always been aware of the many limitations of the rotary engine. When the static style engines became more reliable, gave better specific weights and fuel consumption, the days of the rotary engine were numbered.

Слайд 6

Horizontally-Opposed Engines

An horizontally-opposed engine, also call a flat

or boxer engine, has two banks of cylinders on

opposite sides of a centrally located crankcase. The engine is either air cooled or liquid cooled, but air cooled versions predominate. Opposed engines are mounted with the crankshaft horizontal in airplanes, but may be mounted with the crankshaft vertical in helicopters. Due to the cylinder layout, reciprocating forces tend to cancel, resulting in a smooth running engine. Unlike a radial engine, an opposed engine does not experience any problems with hydrostatic lock.

Слайд 7

V-Type Engines

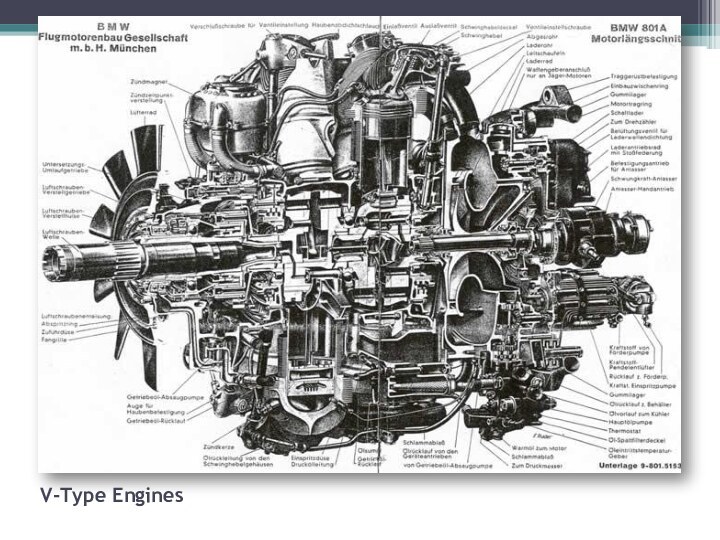

Cylinders in this engine are arranged in

two in-line banks, tilted 30-60 degrees apart from each

other. The vast majority of V engines are water-cooled. The V design provides a higher power-to-weight ratio than an inline engine, while still providing a small frontal area. Perhaps the most famous example of this design is the legendary Rolls-Royce Merlin engine, a 27-litre 60° V12 engine used in, among others, the Spitfires that played a major role in the Battle of Britain.

Слайд 9

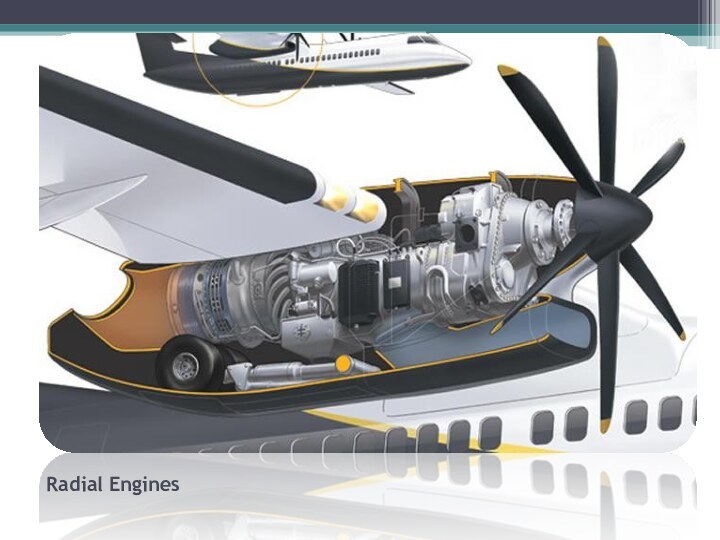

Radial Engines

This type of engine has one or

more rows of cylinders arranged in a circle around

a centrally-located crankcase. Each row must have an odd number of cylinders in order to produce smooth operation. A radial engine has only one crank throw per row and a relatively small crankcase, resulting in a favorable power to weight ratio. Because the cylinder arrangement exposes a large amount of the engine's heat radiating surfaces to the air and tends to cancel reciprocating forces, radials tend to cool evenly and run smoothly. The lower cylinders, which are under the crankcase, may collect oil when the engine has been stopped for an extended period. If this oil is not cleared from the cylinders prior to starting the engine, serious damage due to hydrostatic lock may occur. In military aircraft designs, the large frontal area of the engine acted as an extra layer of armor for the pilot. However, the large frontal area also resulted in aircraft with a blunt and aerodynamically inefficient profile.

Слайд 11

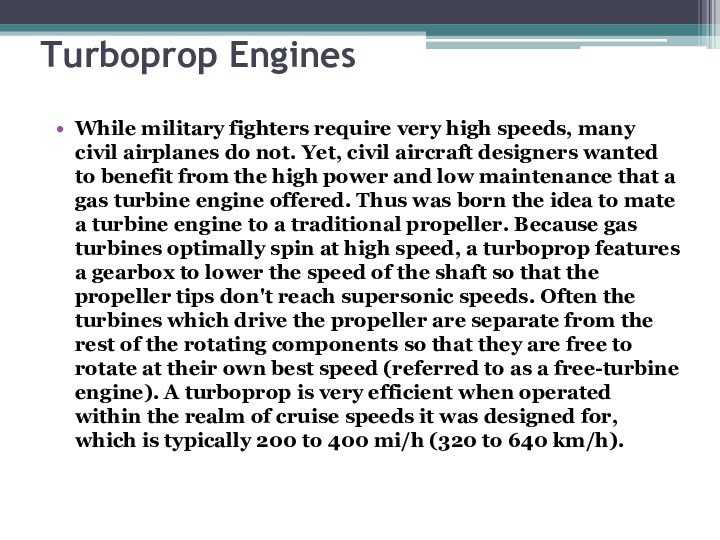

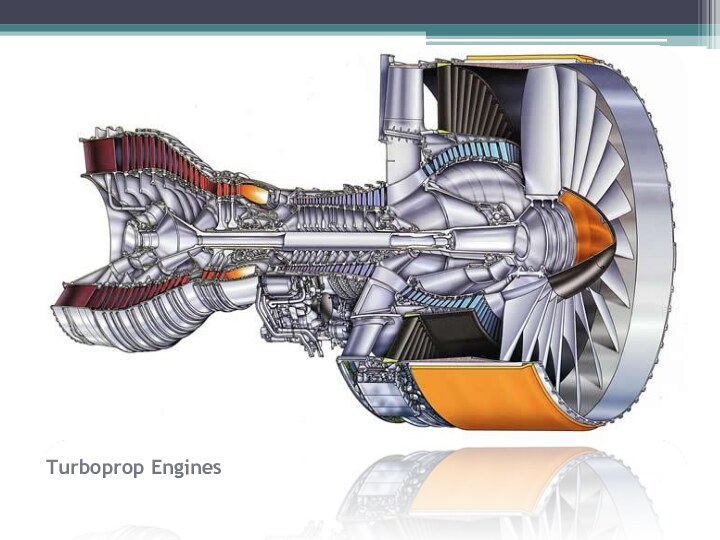

Turboprop Engines

While military fighters require very high speeds,

many civil airplanes do not. Yet, civil aircraft designers

wanted to benefit from the high power and low maintenance that a gas turbine engine offered. Thus was born the idea to mate a turbine engine to a traditional propeller. Because gas turbines optimally spin at high speed, a turboprop features a gearbox to lower the speed of the shaft so that the propeller tips don't reach supersonic speeds. Often the turbines which drive the propeller are separate from the rest of the rotating components so that they are free to rotate at their own best speed (referred to as a free-turbine engine). A turboprop is very efficient when operated within the realm of cruise speeds it was designed for, which is typically 200 to 400 mi/h (320 to 640 km/h).

Слайд 13

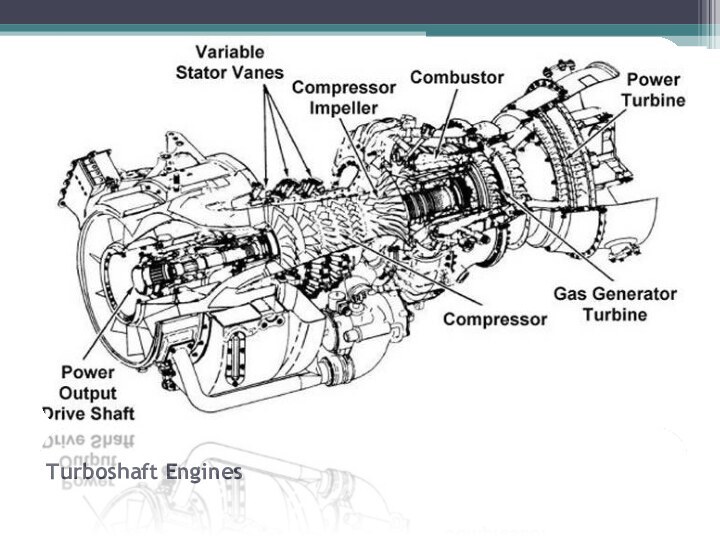

Turboshaft Engines

Turboshaft engines are used primarily for helicopters

and auxiliary power units. A turboshaft engine is very

similar to a turboprop, with a key difference: In a turboprop the propeller is supported by the engine, and the engine is bolted to the airframe. In a turboshaft, the engine does not provide any direct physical support to the helicopter's rotors. The rotor is connected to a transmission, which itself is bolted to the airframe, and the turboshaft engine simply feeds the transmission via a rotating shaft. The distinction is seen by some as a slim one, as in some cases aircraft companies make both turboprop and turboshaft engines based on the same design.

Слайд 15

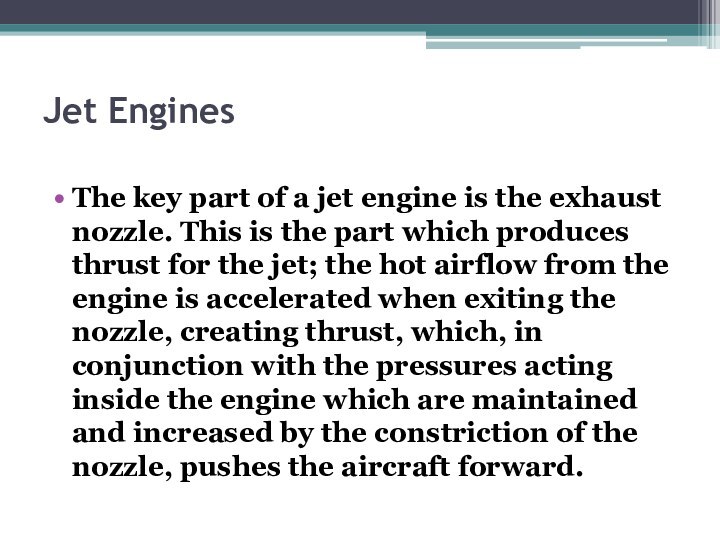

Jet Engines

The key part of a jet engine

is the exhaust nozzle. This is the part which

produces thrust for the jet; the hot airflow from the engine is accelerated when exiting the nozzle, creating thrust, which, in conjunction with the pressures acting inside the engine which are maintained and increased by the constriction of the nozzle, pushes the aircraft forward.

Слайд 17

Turbojet Engines

A turbojet is a type of gas

turbine engine that was originally developed for military fighters

during World War II. A turbojet is the simplest of all aircraft gas turbines. It features a compressor to draw air in and compress it, a combustion section which adds fuel and ignites it, one or more turbines that extract power from the expanding exhaust gases to drive the compressor, and an exhaust nozzle which accelerates the exhaust out the back of the engine to create thrust. When turbojets were introduced, the top speed of fighter aircraft equipped with them was at least 100 miles per hour faster than competing piston-driven aircraft. The relative simplicity of turbojet designs lent themselves to wartime production, but the war ended before any turbojets could be mass-produced. In the years after the war, the drawbacks of the turbojet gradually became apparent. Below about Mach 2, turbojets are very fuel inefficient and create tremendous amounts of noise. The early designs also respond very slowly to power changes, a fact which killed many experienced pilots when they attempted the transition to jets. These drawbacks eventually led to the downfall of the pure turbojet, and only a handful of types are still in production. The last airliner that used turbojets was the Concorde, whose Mach 2 airspeed permitted the engine to be highly efficient.

Слайд 19

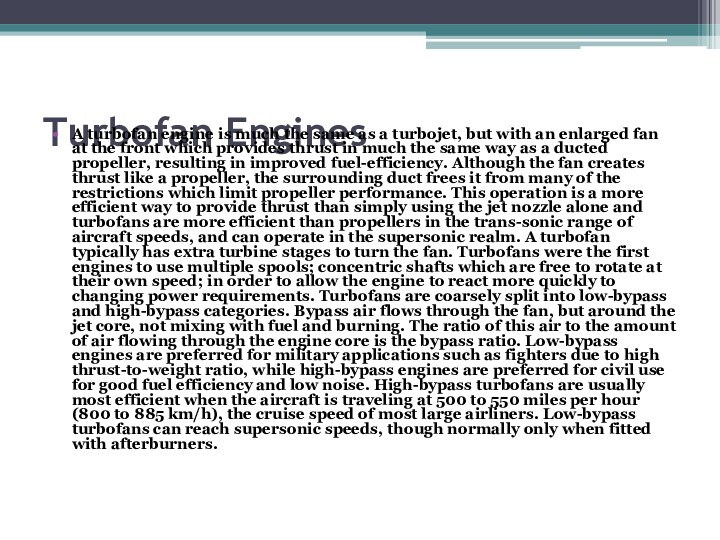

Turbofan Engines

A turbofan engine is much the same

as a turbojet, but with an enlarged fan at

the front which provides thrust in much the same way as a ducted propeller, resulting in improved fuel-efficiency. Although the fan creates thrust like a propeller, the surrounding duct frees it from many of the restrictions which limit propeller performance. This operation is a more efficient way to provide thrust than simply using the jet nozzle alone and turbofans are more efficient than propellers in the trans-sonic range of aircraft speeds, and can operate in the supersonic realm. A turbofan typically has extra turbine stages to turn the fan. Turbofans were the first engines to use multiple spools; concentric shafts which are free to rotate at their own speed; in order to allow the engine to react more quickly to changing power requirements. Turbofans are coarsely split into low-bypass and high-bypass categories. Bypass air flows through the fan, but around the jet core, not mixing with fuel and burning. The ratio of this air to the amount of air flowing through the engine core is the bypass ratio. Low-bypass engines are preferred for military applications such as fighters due to high thrust-to-weight ratio, while high-bypass engines are preferred for civil use for good fuel efficiency and low noise. High-bypass turbofans are usually most efficient when the aircraft is traveling at 500 to 550 miles per hour (800 to 885 km/h), the cruise speed of most large airliners. Low-bypass turbofans can reach supersonic speeds, though normally only when fitted with afterburners.

Слайд 21

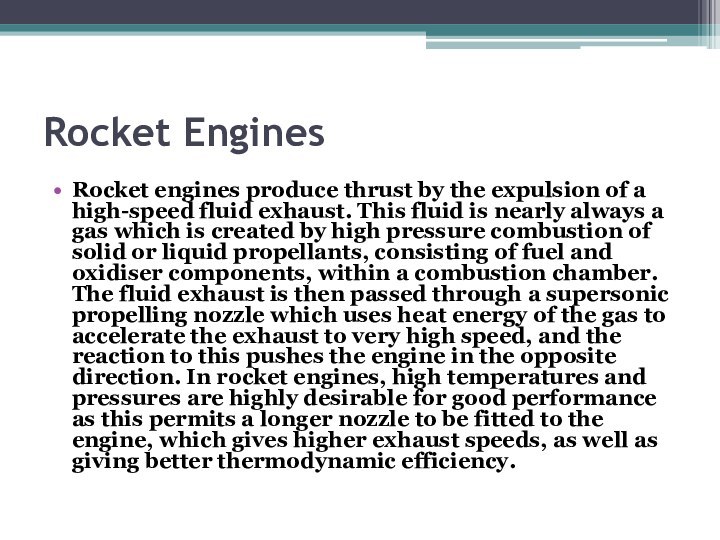

Rocket Engines

Rocket engines produce thrust by the expulsion

of a high-speed fluid exhaust. This fluid is nearly

always a gas which is created by high pressure combustion of solid or liquid propellants, consisting of fuel and oxidiser components, within a combustion chamber. The fluid exhaust is then passed through a supersonic propelling nozzle which uses heat energy of the gas to accelerate the exhaust to very high speed, and the reaction to this pushes the engine in the opposite direction. In rocket engines, high temperatures and pressures are highly desirable for good performance as this permits a longer nozzle to be fitted to the engine, which gives higher exhaust speeds, as well as giving better thermodynamic efficiency.

Слайд 23

Aircraft spend the vast majority of their time

travelling at high speed. This allows an aircraft engine

to be air cooled, as opposed to requiring a radiator. With the absence of a radiator, aircraft engines can boast lower weight and less complexity. The amount of air flow an engine receives is usually carefully designed according to expected speed and altitude of the aircraft in order to maintain the engine at the optimal temperature.

Слайд 25

Generalized Aircraft Engine Information

The power of an internal

combustion reciprocating or turbine aircraft engine is rated in

units of power delivered to the propeller (typically horsepower) which is torque multiplied by crankshaft revolutions per minute (RPM).