- Главная

- Разное

- Бизнес и предпринимательство

- Образование

- Развлечения

- Государство

- Спорт

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Религиоведение

- Черчение

- Физкультура

- ИЗО

- Психология

- Социология

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Что такое findslide.org?

FindSlide.org - это сайт презентаций, докладов, шаблонов в формате PowerPoint.

Обратная связь

Email: Нажмите что бы посмотреть

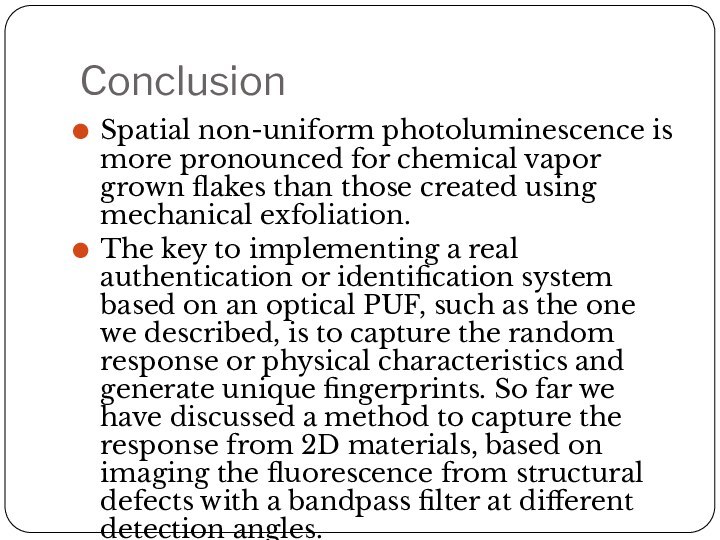

Презентация на тему Optical identification using imperfections in 2D materials

Содержание

- 2. IntroductionThe ability to uniquely identify an object

- 3.

- 4. ObjectiveTo analise a proposed simple optical technique to read unique information from nanometer-scale defects in 2D materials.

- 5. TasksMethodResults for WS2 from mechanically exfoliationResults for WS2 from chemical vapor depositionConclusion

- 6. MethodMeasurement apparatus, in which the photoluminescence from

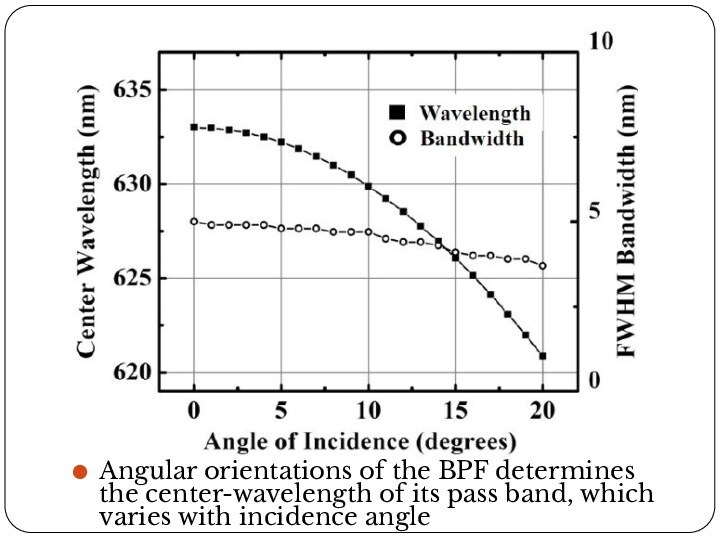

- 7. Angular orientations of the BPF determines the

- 8. Concept of the angular selective transmissionChanging the

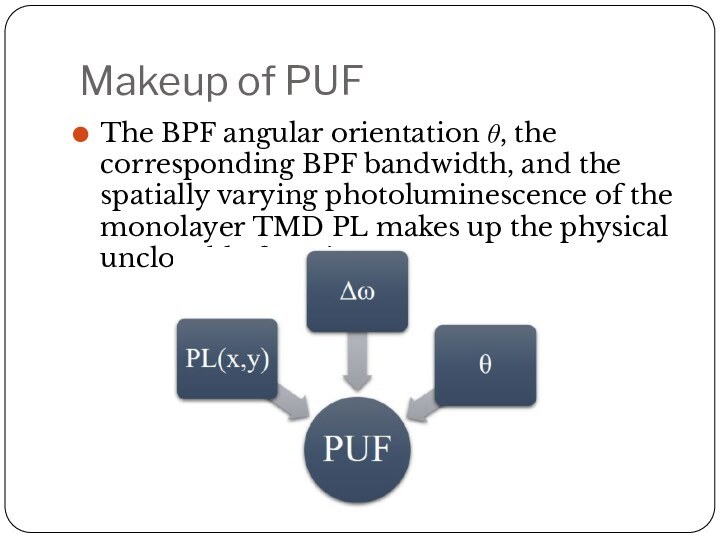

- 9. Makeup of PUFThe BPF angular orientation θ, the

- 10. Results for WS2 from mechanically exfoliation

- 11. Results for WS2 from chemical vapor depositionAngular-dependent

- 12. Angular dependent PL images of WS2 monolayer

- 13. Скачать презентацию

- 14. Похожие презентации

IntroductionThe ability to uniquely identify an object or device is important for authentication. Imperfections, locked into structures during fabrication, can be used to provide a fingerprint that is challenging to reproduce.