- Главная

- Разное

- Бизнес и предпринимательство

- Образование

- Развлечения

- Государство

- Спорт

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Религиоведение

- Черчение

- Физкультура

- ИЗО

- Психология

- Социология

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

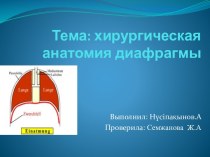

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Что такое findslide.org?

FindSlide.org - это сайт презентаций, докладов, шаблонов в формате PowerPoint.

Обратная связь

Email: Нажмите что бы посмотреть

Презентация на тему Pipeline valve types and classification

Содержание

- 2. OverviewValve classificationValve typesValve usageBlock valves/ shut-down valves/ shut-off valves

- 3. Valve itselfVALVEcan stand for various Russian terms

- 4. Valve classificationValves can be classified in different

- 5. Valve classification1. by function or purpose: • To

- 6. Valve classification2. by closure member or mechanical

- 7. Valve usageObligatory valve placement:Pipeline itselfPump and compressor stationsPressure regulator stationsMeter runsLauncher and receiver stationsBreakout tankageDistribution manifolds

- 8. Valve usageBlock valve requirements:Full port gate valveBlock-and-bleed

- 9. Valve usageBreakout tank valves:Assurance of each tank

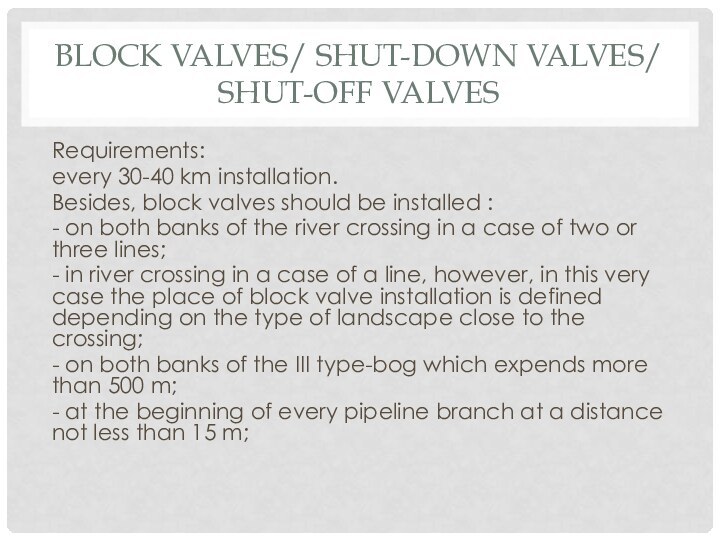

- 10. Block valves/ shut-down valves/ shut-off valvesRequirements:every 30-40

- 11. Скачать презентацию

- 12. Похожие презентации

OverviewValve classificationValve typesValve usageBlock valves/ shut-down valves/ shut-off valves

Слайд 2

Overview

Valve classification

Valve types

Valve usage

Block valves/ shut-down valves/ shut-off

valves

Слайд 3

Valve itself

VALVE

can stand for various

Russian terms

арматура,

задвижки, клапаны

Valve is an integral component used for controlling

& regulating flow of liquids or gases to maintain the process parameters such as flow, pressure etc.

Слайд 4

Valve classification

Valves can be classified in different ways:

the

function or purpose of application

2. the closure member or

mechanical motion

Слайд 5

Valve classification

1. by function or purpose:

• To start

and stop flow of fluids

• To regulate, throttle and control

fluid flow or pressure• To prevent back-flow

• To relieve excess pressure / vacuum

Thus, the following types are distinguished:

•Shut-off Valves (Block valves/ shut-down)

•Non-return Valves (back-pressure valve)

•Control Valves

•Safety Valves (pressure-relief valve, pressure safety valve, pressure/vacuum-relief valve, emergency relief valve)

Слайд 6

Valve classification

2. by closure member or mechanical motion

• Linear

Motion Valves. The Valves in which the closure member,

as in gate, globe, diaphragm, pinch,, moves in a straight line to allow, stop, or throttle the flow.• Rotary Motion Valves. When the Valve-closure member travels along an angular or circular path, as in butterfly, ball, plug, eccentric- and Swing Check Valves, the Valves are called rotary motion Valves.

• Quarter Turn Valves. Some rotary motion Valves require approximately a quarter turn, 0 through 90°, motion of the stem to go to fully open from a fully closed position or vice versa.

Слайд 7

Valve usage

Obligatory valve placement:

Pipeline itself

Pump and compressor stations

Pressure

regulator stations

Meter runs

Launcher and receiver stations

Breakout tankage

Distribution manifolds

Слайд 8

Valve usage

Block valve requirements:

Full port gate valve

Block-and-bleed design

(to insure leak-tight performance)

Can be equipped with motor operator

valve.Branch or lateral valve:

Leak tight

Block-and-bleed design

Full-port design is not necessary

Слайд 9

Valve usage

Breakout tank valves:

Assurance of each tank isolation

by inlet and outlet valves.

Pump station valves:

Suction sides of

the station and discharge side to the pipeline, so there are suction valves and discharge valves.Pipeline control valves:

Work in concert with centrifugal pumps

Usually vee-ball design

Controller presence

Слайд 10

Block valves/ shut-down valves/ shut-off valves

Requirements:

every 30-40 km

installation.

Besides, block valves should be installed :

- on

both banks of the river crossing in a case of two or three lines;- in river crossing in a case of a line, however, in this very case the place of block valve installation is defined depending on the type of landscape close to the crossing;

- on both banks of the III type-bog which expends more than 500 m;

- at the beginning of every pipeline branch at a distance not less than 15 m;