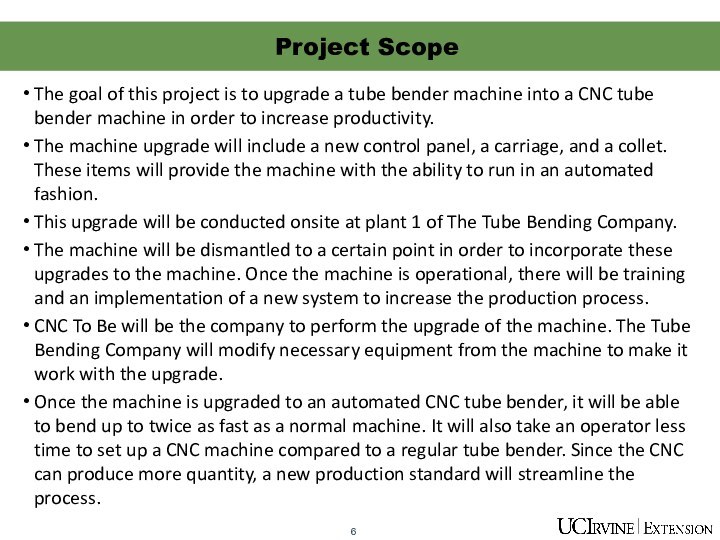

a tube bender machine into a CNC tube bender

machine in order to increase productivity.

The machine upgrade will include a new control panel, a carriage, and a collet. These items will provide the machine with the ability to run in an automated fashion.

This upgrade will be conducted onsite at plant 1 of The Tube Bending Company.

The machine will be dismantled to a certain point in order to incorporate these upgrades to the machine. Once the machine is operational, there will be training and an implementation of a new system to increase the production process.

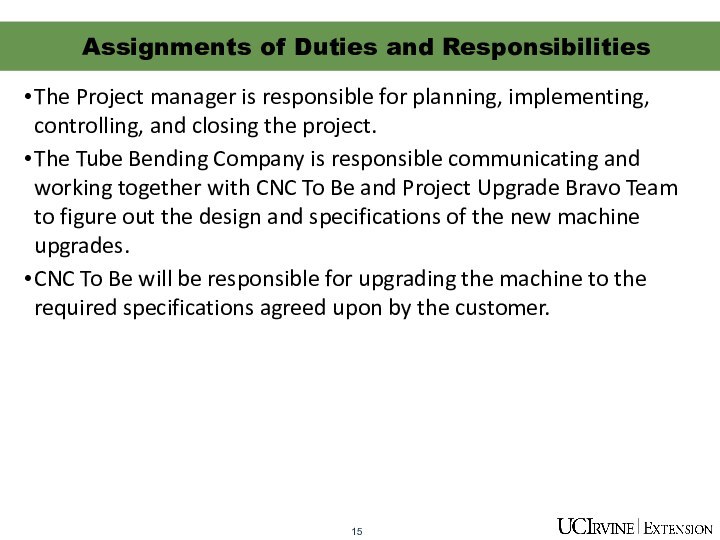

CNC To Be will be the company to perform the upgrade of the machine. The Tube Bending Company will modify necessary equipment from the machine to make it work with the upgrade.

Once the machine is upgraded to an automated CNC tube bender, it will be able to bend up to twice as fast as a normal machine. It will also take an operator less time to set up a CNC machine compared to a regular tube bender. Since the CNC can produce more quantity, a new production standard will streamline the process.

Project Scope