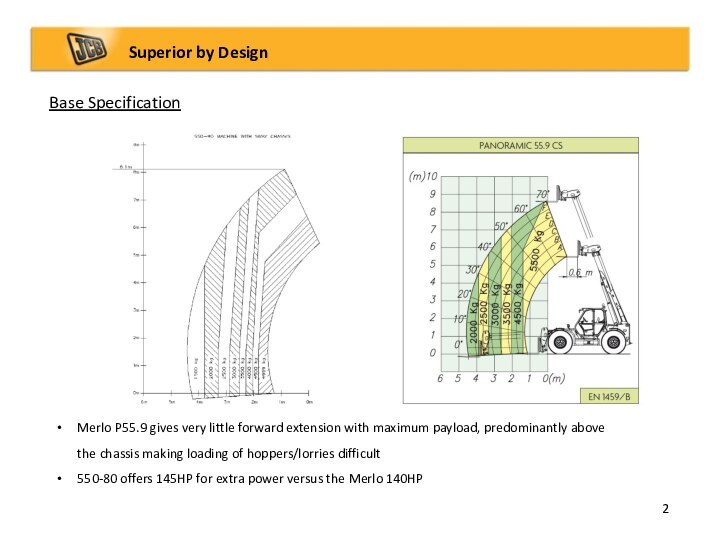

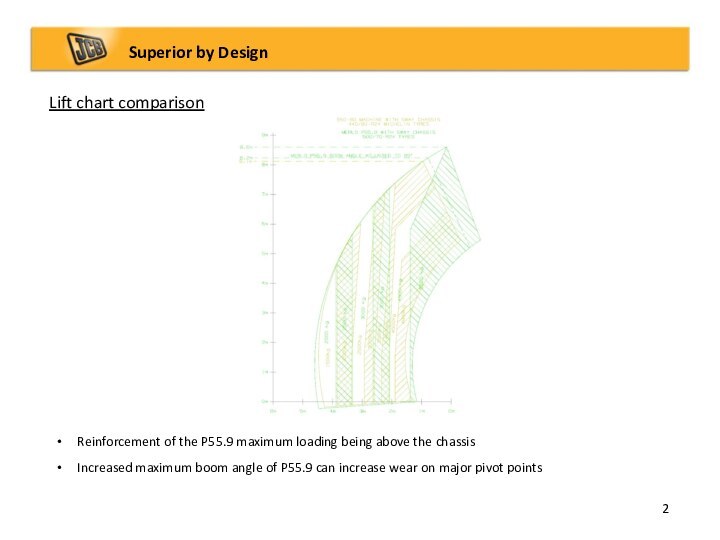

forward extension with maximum payload, predominantly above the chassis

making loading of hoppers/lorries difficult550-80 offers 145HP for extra power versus the Merlo 140HP

FindSlide.org - это сайт презентаций, докладов, шаблонов в формате PowerPoint.

Email: Нажмите что бы посмотреть

3

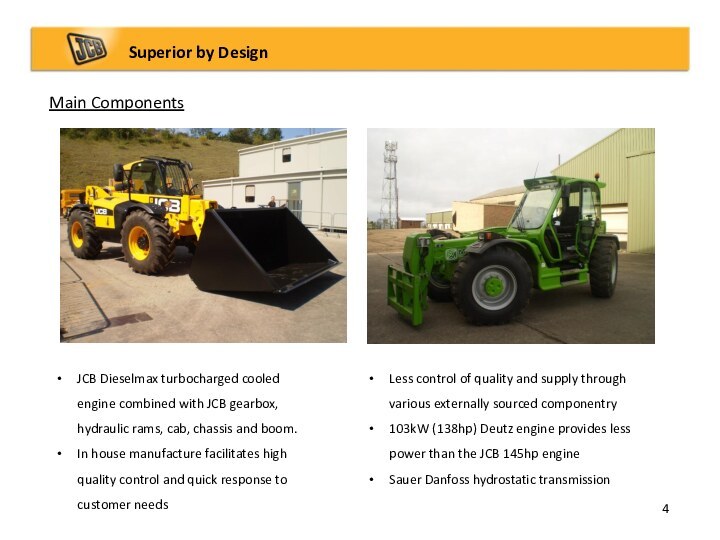

Less control of quality and supply through various externally sourced componentry

103kW (138hp) Deutz engine provides less power than the JCB 145hp engine

Sauer Danfoss hydrostatic transmission

4

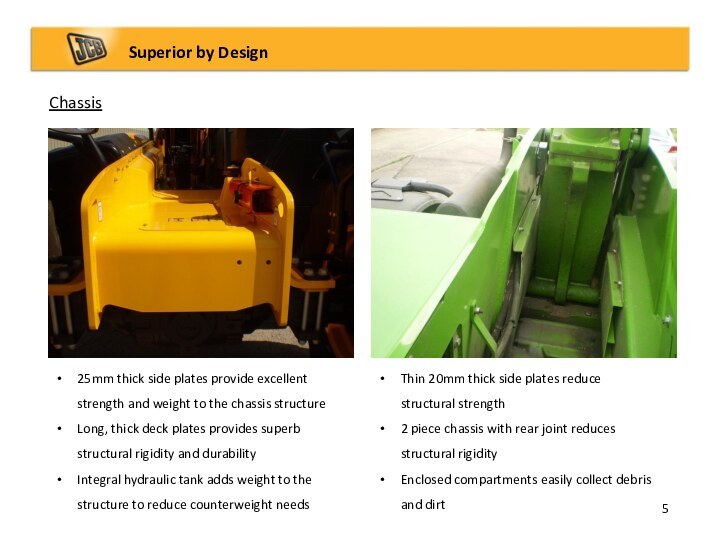

Thin 20mm thick side plates reduce structural strength

2 piece chassis with rear joint reduces structural rigidity

Enclosed compartments easily collect debris and dirt

5

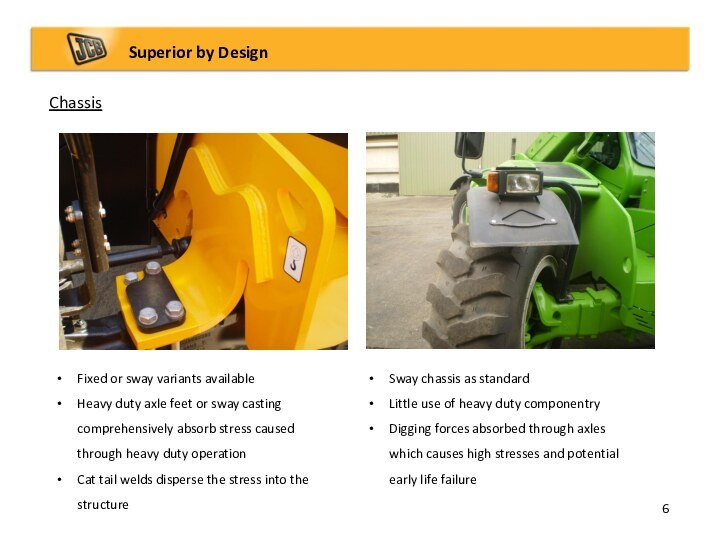

Sway chassis as standard

Little use of heavy duty componentry

Digging forces absorbed through axles which causes high stresses and potential early life failure

6

7

Merlo uses under-slung tilt ram and pivot linkage

Reduced productivity particularly when re-handling

Minimal boom nose reduces structural strength and integrity

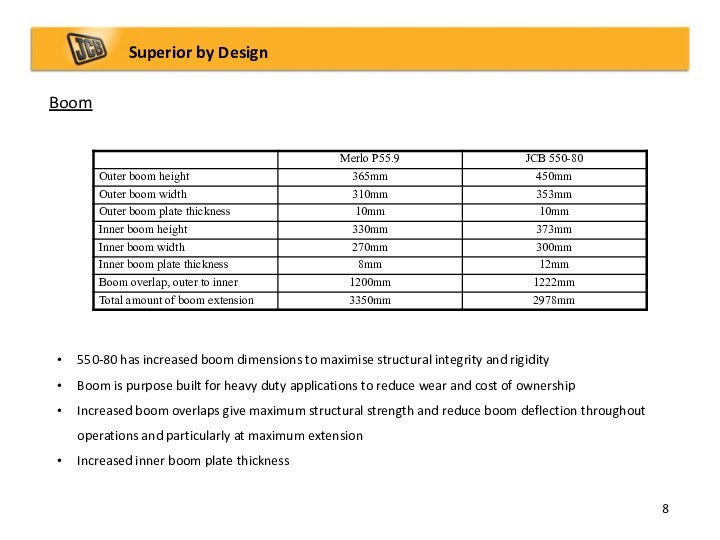

8

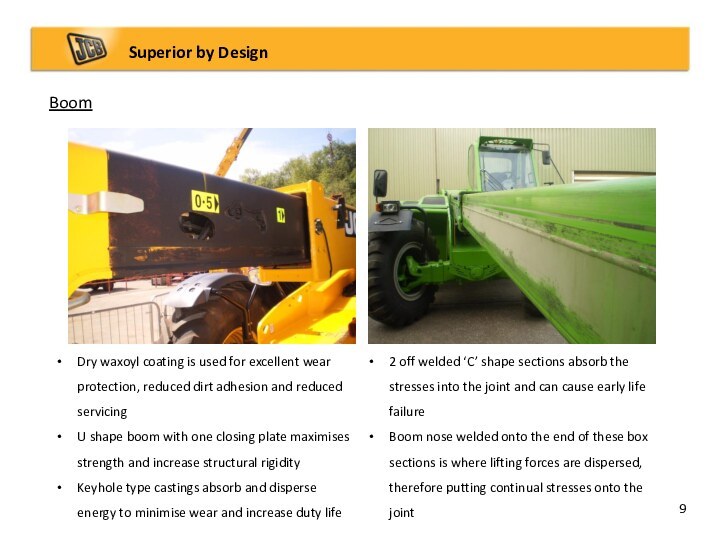

9

2 off welded ‘C’ shape sections absorb the stresses into the joint and can cause early life failure

Boom nose welded onto the end of these box sections is where lifting forces are dispersed, therefore putting continual stresses onto the joint

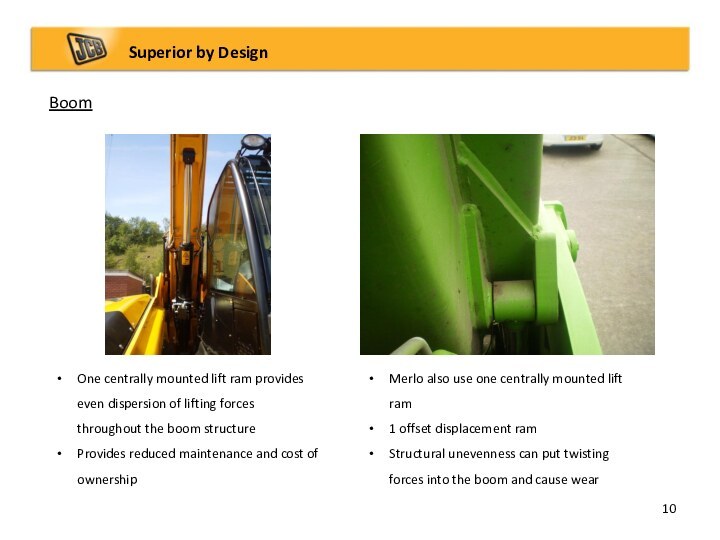

Merlo also use one centrally mounted lift ram

1 offset displacement ram

Structural unevenness can put twisting forces into the boom and cause wear

10

11

12

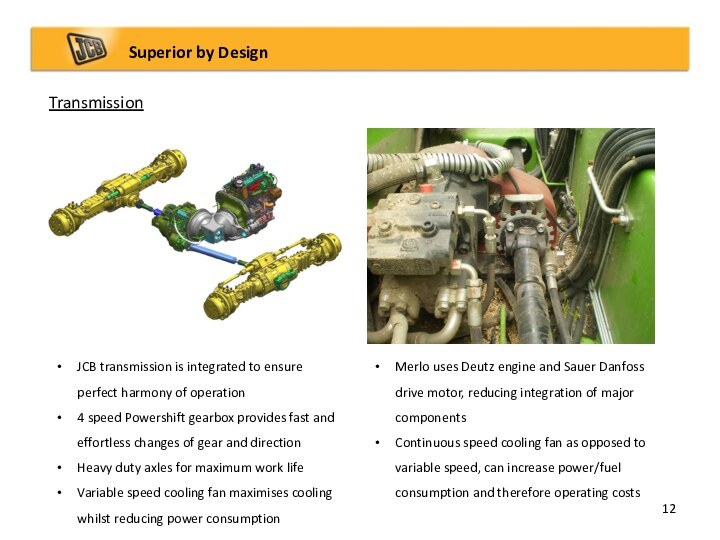

Merlo uses Deutz engine and Sauer Danfoss drive motor, reducing integration of major components

Continuous speed cooling fan as opposed to variable speed, can increase power/fuel consumption and therefore operating costs

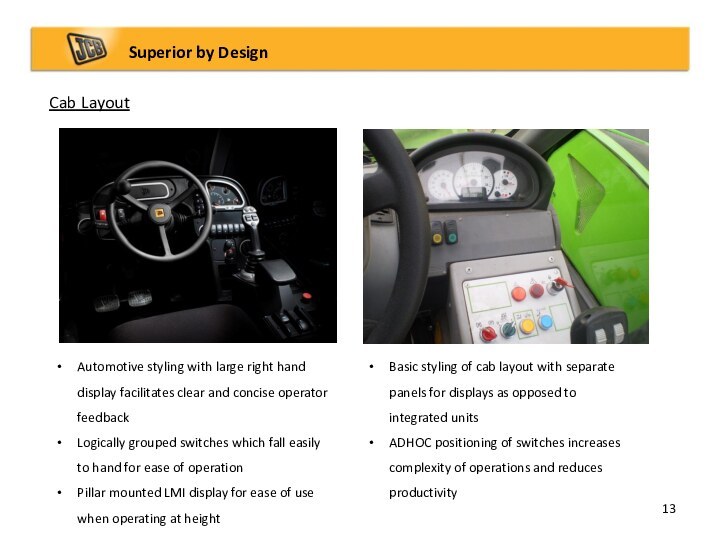

Basic styling of cab layout with separate panels for displays as opposed to integrated units

ADHOC positioning of switches increases complexity of operations and reduces productivity

13

ADHOC positioning of joystick and armrest facilitate an uncomfortable operator environment to increase fatigue

Cab mounted option only reduces machine versatility

‘Dead man switch’ uncomfortable to use

14

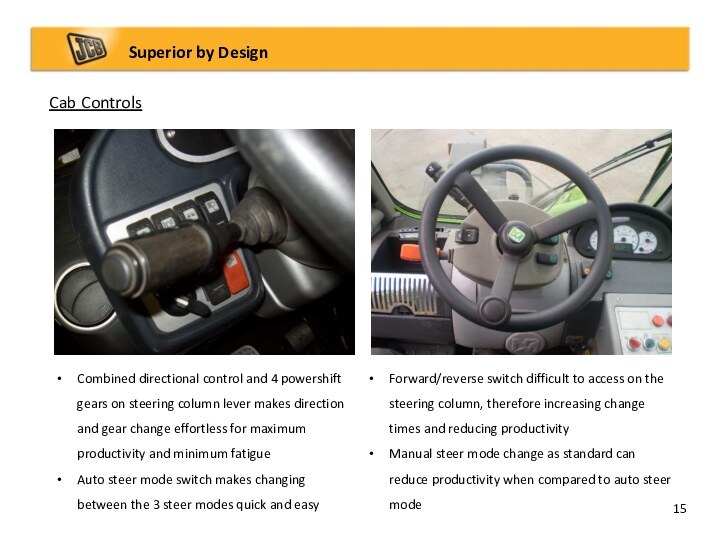

Forward/reverse switch difficult to access on the steering column, therefore increasing change times and reducing productivity

Manual steer mode change as standard can reduce productivity when compared to auto steer mode

15

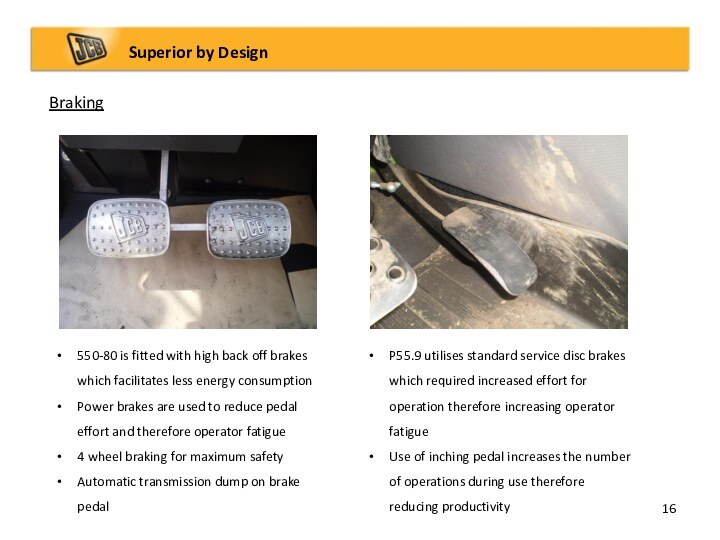

P55.9 utilises standard service disc brakes which required increased effort for operation therefore increasing operator fatigue

Use of inching pedal increases the number of operations during use therefore reducing productivity

16

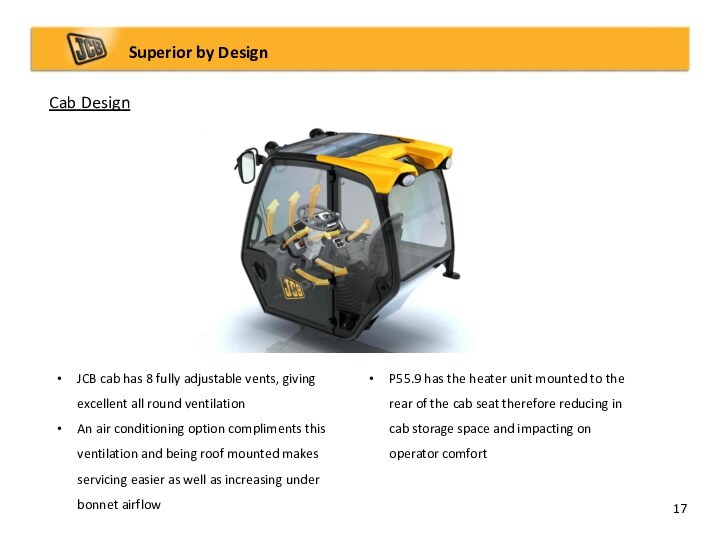

P55.9 has the heater unit mounted to the rear of the cab seat therefore reducing in cab storage space and impacting on operator comfort

17

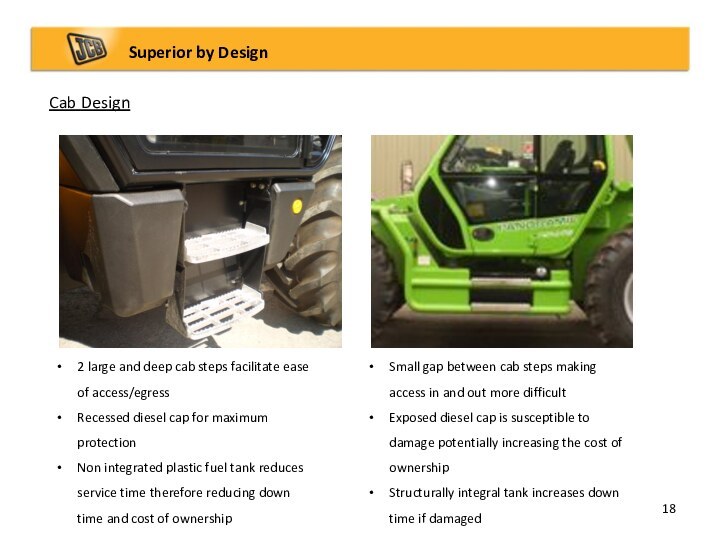

Small gap between cab steps making access in and out more difficult

Exposed diesel cap is susceptible to damage potentially increasing the cost of ownership

Structurally integral tank increases down time if damaged

18

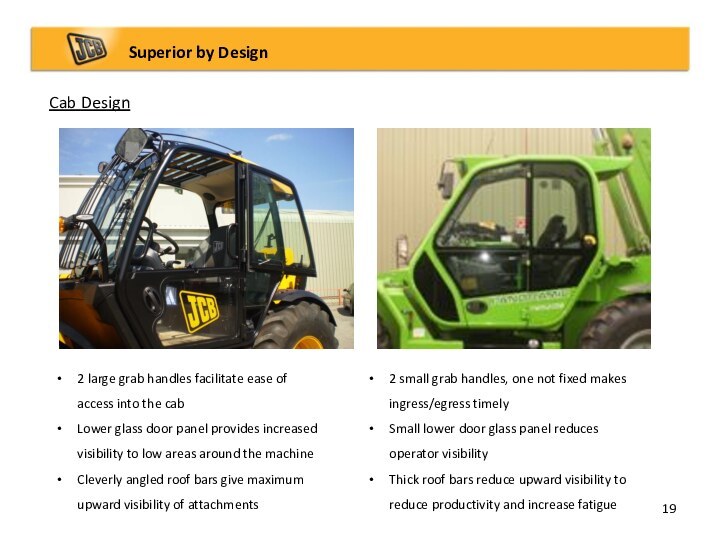

2 small grab handles, one not fixed makes ingress/egress timely

Small lower door glass panel reduces operator visibility

Thick roof bars reduce upward visibility to reduce productivity and increase fatigue

19

Service access is dramatically restricted through low opening bonnet

Fixed engine under cover makes all round access to the engine timely therefore increasing downtime and reducing productivity

20

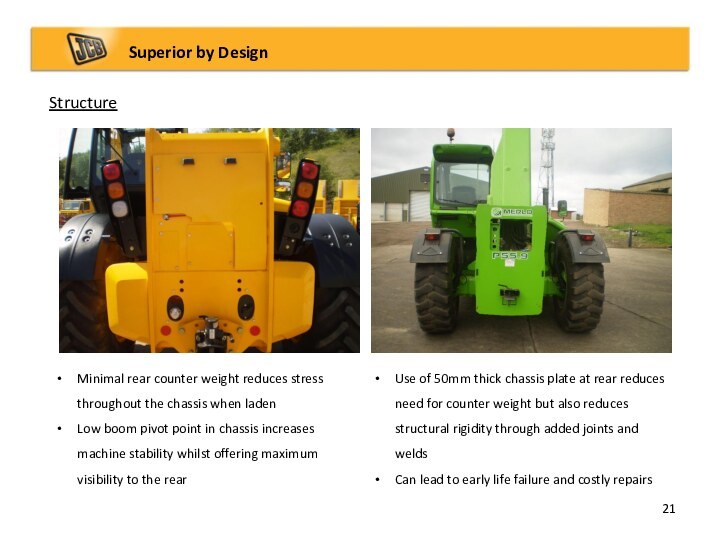

Use of 50mm thick chassis plate at rear reduces need for counter weight but also reduces structural rigidity through added joints and welds

Can lead to early life failure and costly repairs

21

Static rear and front lights mounted on fixed front and steering rear fender arms

High exposure to damage increases ownership costs

22

23