- Главная

- Разное

- Бизнес и предпринимательство

- Образование

- Развлечения

- Государство

- Спорт

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Религиоведение

- Черчение

- Физкультура

- ИЗО

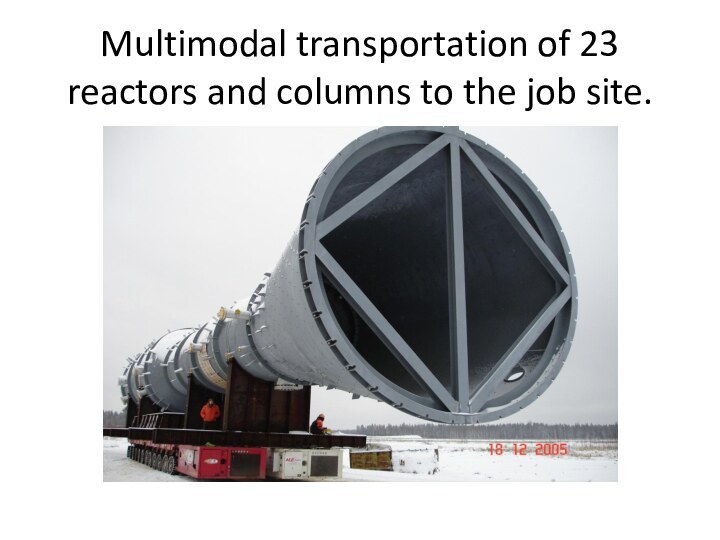

- Психология

- Социология

- Английский язык

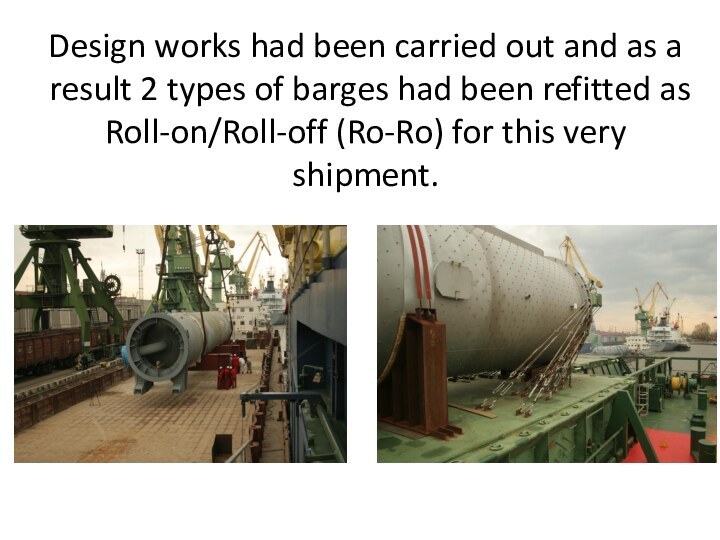

- Астрономия

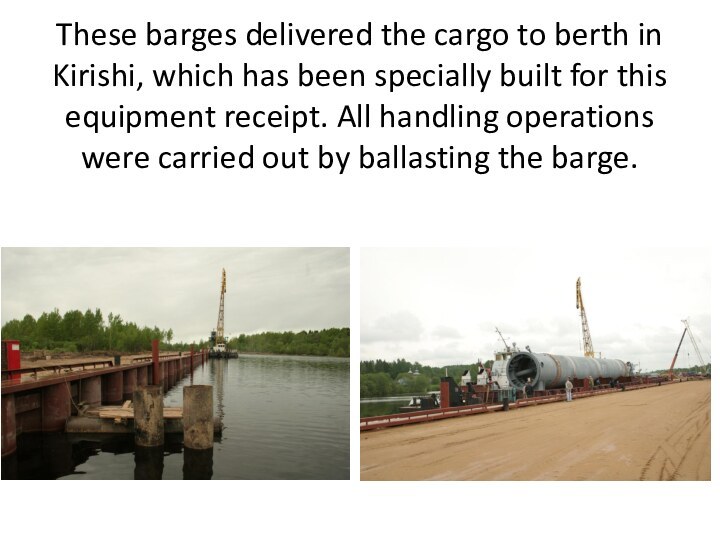

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Что такое findslide.org?

FindSlide.org - это сайт презентаций, докладов, шаблонов в формате PowerPoint.

Обратная связь

Email: Нажмите что бы посмотреть

Презентация на тему ИНКОТЕК КАРГО

Содержание

- 2. INCOTEC GROUP was founded in 1992

- 3. The structure of INCOTEC GROUP was originally

- 4. INCOTEC GROUP consisted of the following departments:

- 5. Port Forwarding Department

- 6. Multimodal Transportation Department

- 7. Railway Transportation Department

- 8. Shipping Agency Department

- 9. Survey Department

- 10. Inland Trucking Department

- 11. Customs Clearance Department

- 12. Project Cargo Transportation Department

- 13. In the year of 2001, September 28th,

- 14. The year of 2005. Customer: Kirishinefteorgsintez (KINEF)

- 15. Multimodal transportation of 23 reactors and columns to the job site.

- 16. Weight up to 1065 MT each, length

- 17. The 1st shipment arrived at the port

- 18. Design works had been carried out and

- 19. These barges delivered the cargo to berth

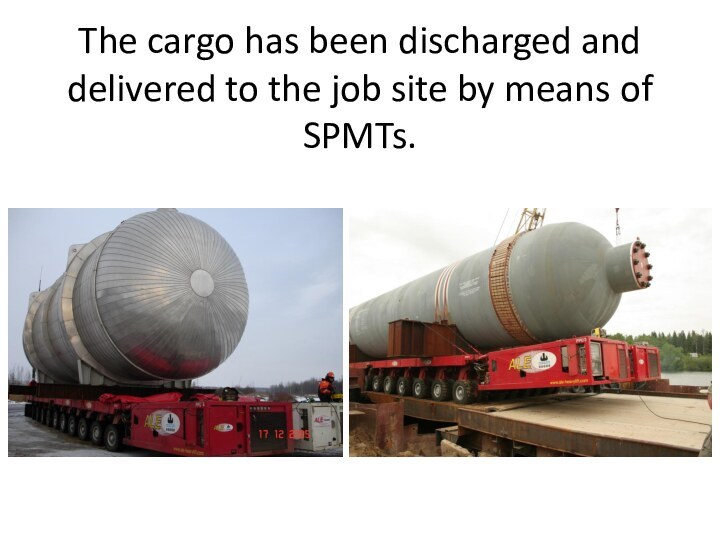

- 20. The cargo has been discharged and delivered to the job site by means of SPMTs.

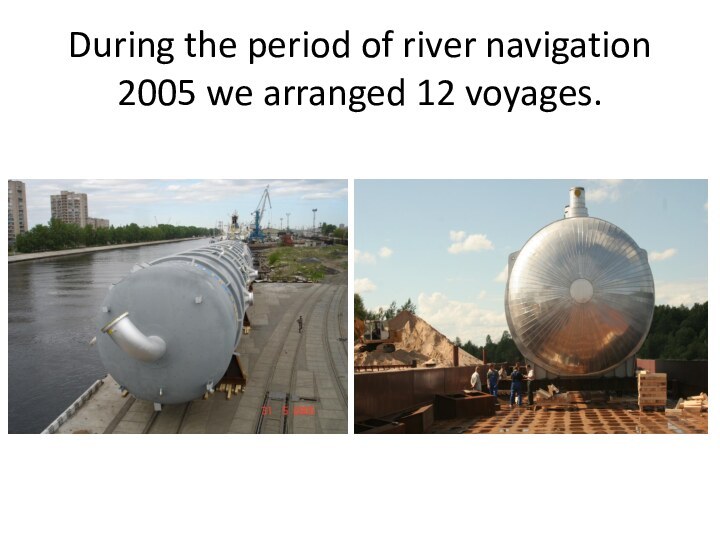

- 21. During the period of river navigation 2005 we arranged 12 voyages.

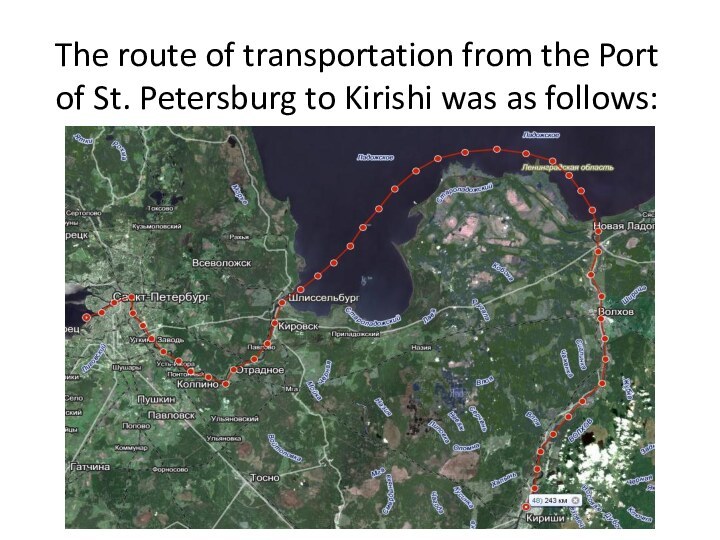

- 22. The route of transportation from the Port of St. Petersburg to Kirishi was as follows:

- 23. Volume shipped - more than 25 000 freight tons.

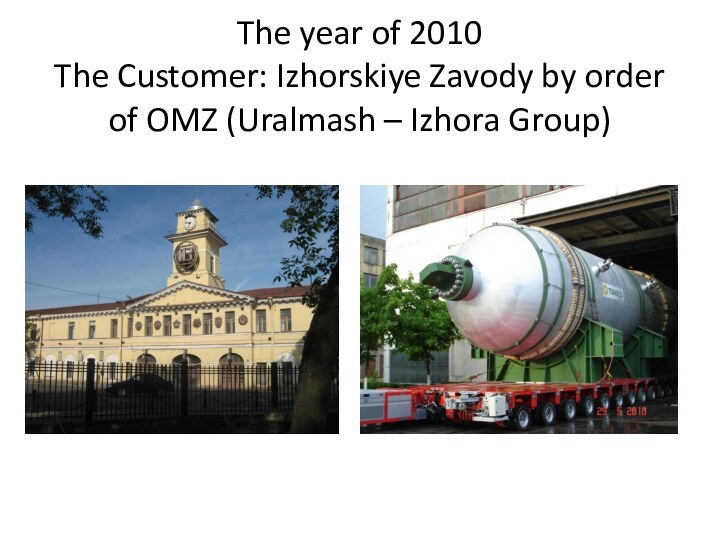

- 24. The year of 2010 The Customer: Izhorskiye Zavody by order of OMZ (Uralmash – Izhora Group)

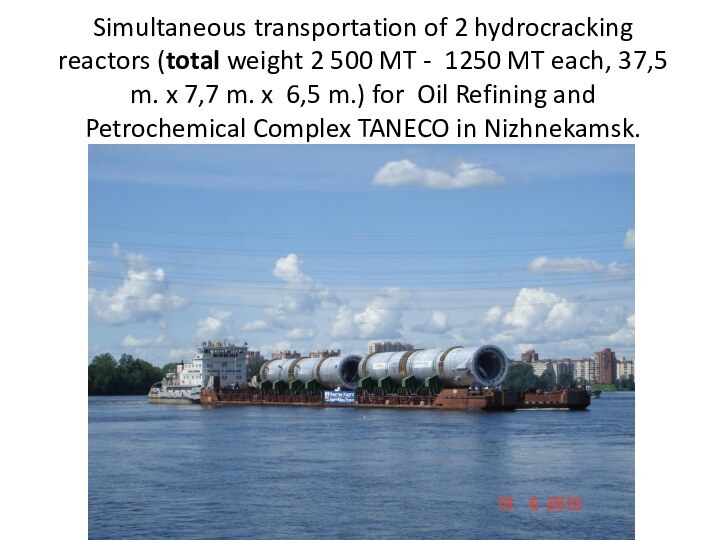

- 25. Simultaneous transportation of 2 hydrocracking reactors (total

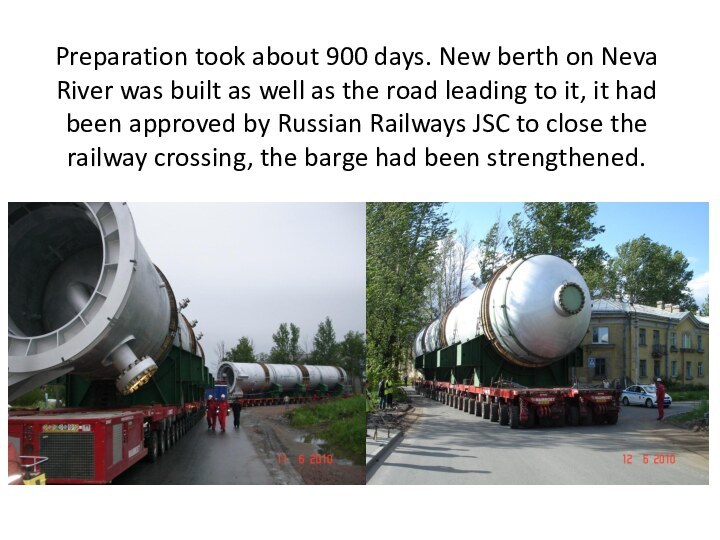

- 26. Preparation took about 900 days. New berth

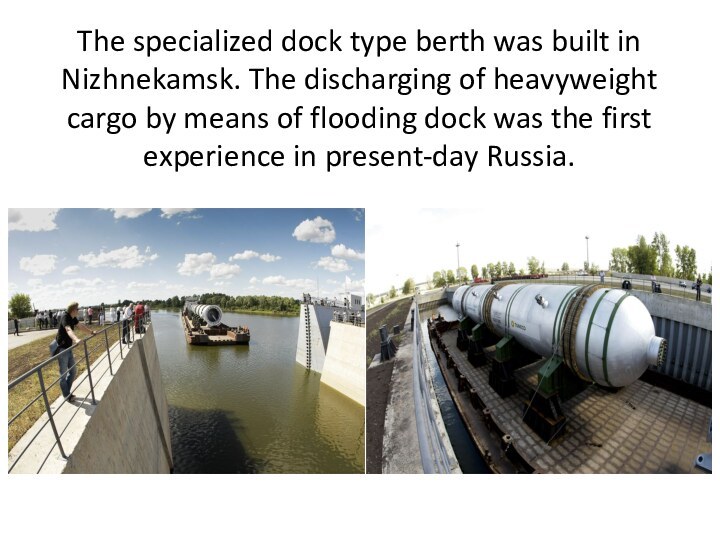

- 27. The specialized dock type berth was built

- 28. Loading operations in Saint Petersburg as well as discharging in Nizhnekamsk were held by Ro-Ro method

- 29. Discharging in Nizhnekamsk

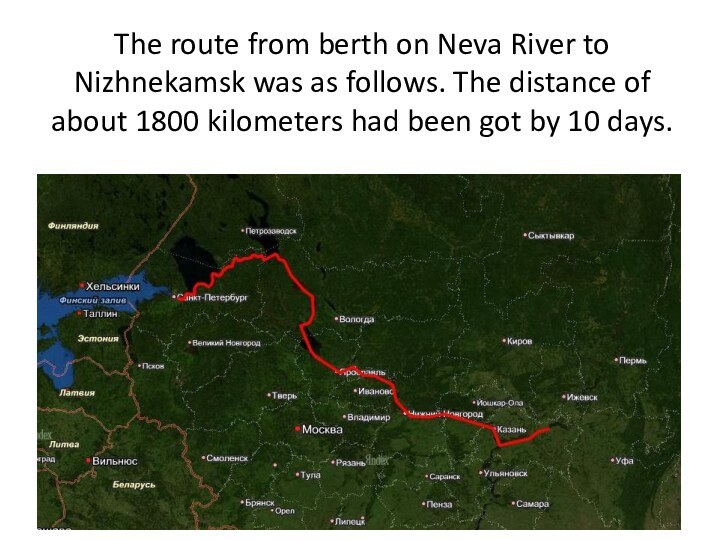

- 30. The route from berth on Neva River

- 31. The project was fulfilled and the cargo was delivered to the Consignee.

- 32. Years of 2010-2012 The Customer: OJSC TANECO (Nizhnekamsk)

- 33. Since 2010 INCOTEC CARGO Ltd was involved

- 34. CCR Plant delivery from South Korea

- 35. For that cargo geared vessel was chartered. She has 2 cranes by 275 MT SWL each.

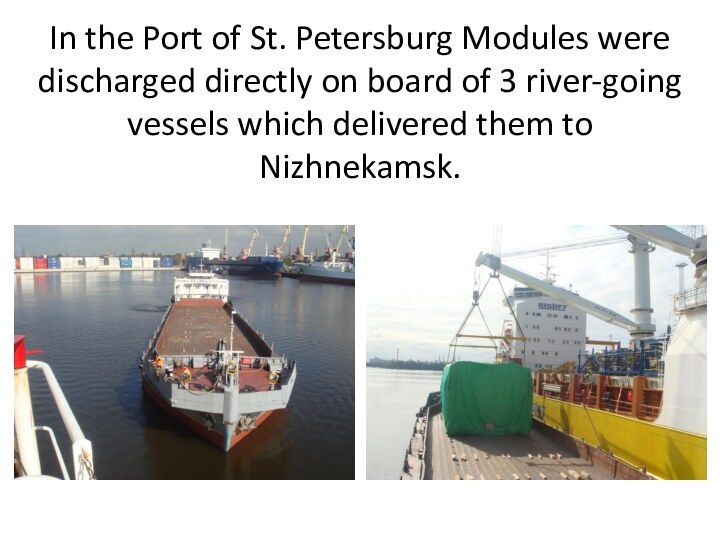

- 36. In the Port of St. Petersburg Modules

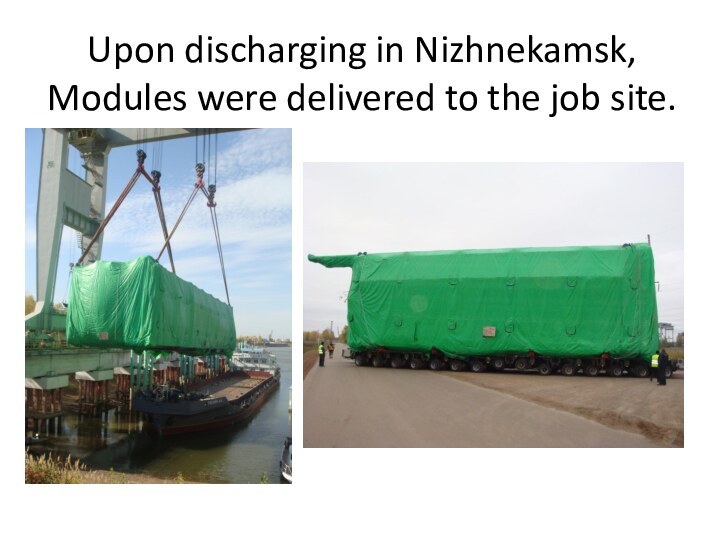

- 37. Upon discharging in Nizhnekamsk, Modules were delivered to the job site.

- 38. Delivery of Reactor Column (45 m. length) from Italy

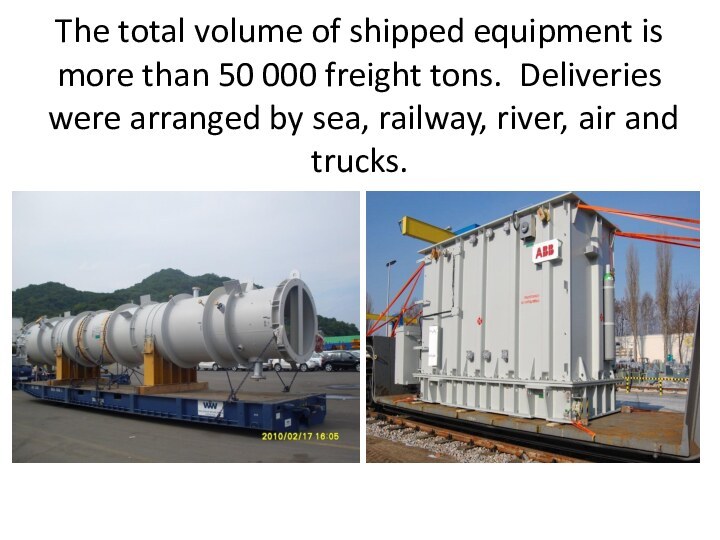

- 39. The total volume of shipped equipment is

- 40. Year of 2012 (November – December) The Customer: Baltiysky Zavod JSC

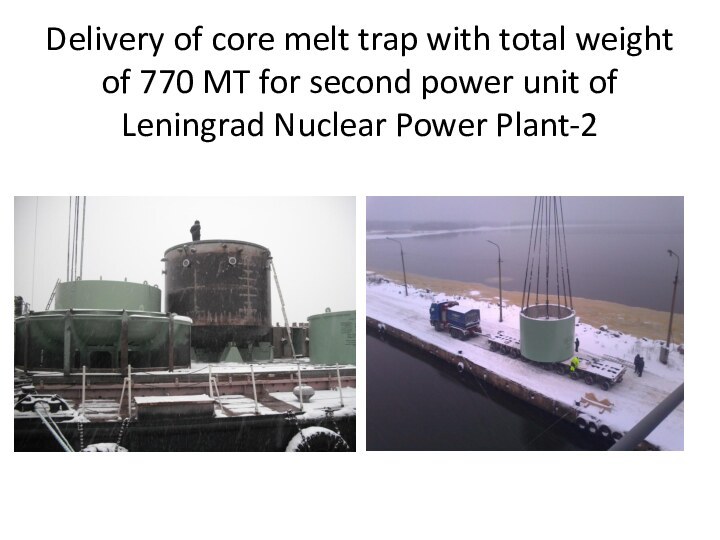

- 41. Delivery of core melt trap with total

- 42. The heaviest items (weight up to 161

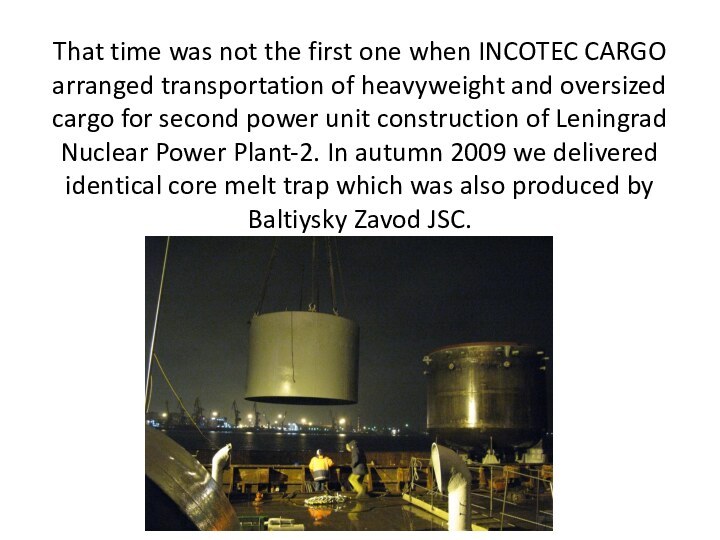

- 43. That time was not the first one

- 44. Among our Customers such Companies

- 45. Скачать презентацию

- 46. Похожие презентации

INCOTEC GROUP was founded in 1992