- Главная

- Разное

- Бизнес и предпринимательство

- Образование

- Развлечения

- Государство

- Спорт

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Религиоведение

- Черчение

- Физкультура

- ИЗО

- Психология

- Социология

- Английский язык

- Астрономия

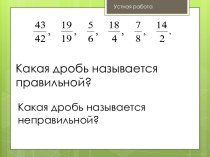

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

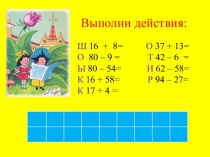

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

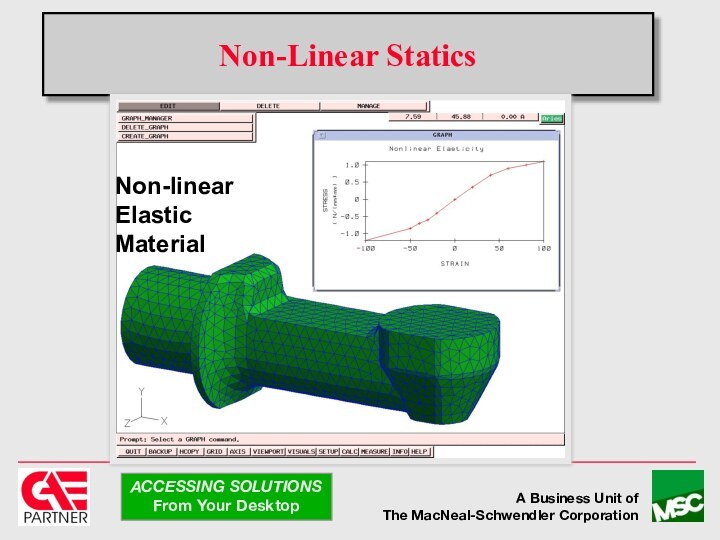

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Что такое findslide.org?

FindSlide.org - это сайт презентаций, докладов, шаблонов в формате PowerPoint.

Обратная связь

Email: Нажмите что бы посмотреть

Презентация на тему по сопромату3

Содержание

- 3. Bob Gilliver MSC/ARIES European Product Marketing and Support Manager

- 4. GeometryFE AnalysisOptimizationMechanismsPlasticsMSC/ARIES Positioning

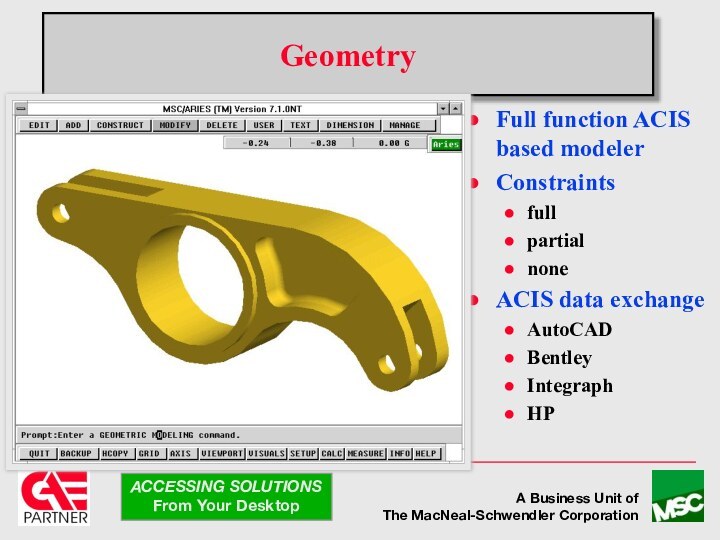

- 5. GeometryFull function ACIS based modelerConstraintsfull partial noneACIS data exchangeAutoCADBentleyIntegraphHP

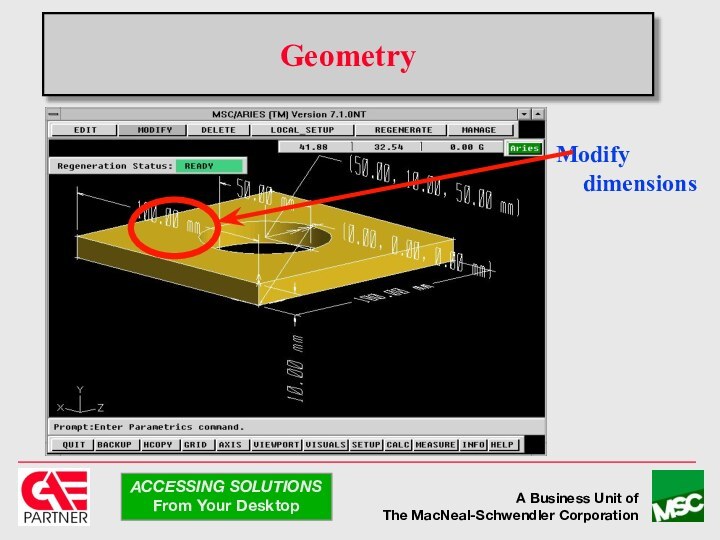

- 6. GeometryModify dimensions

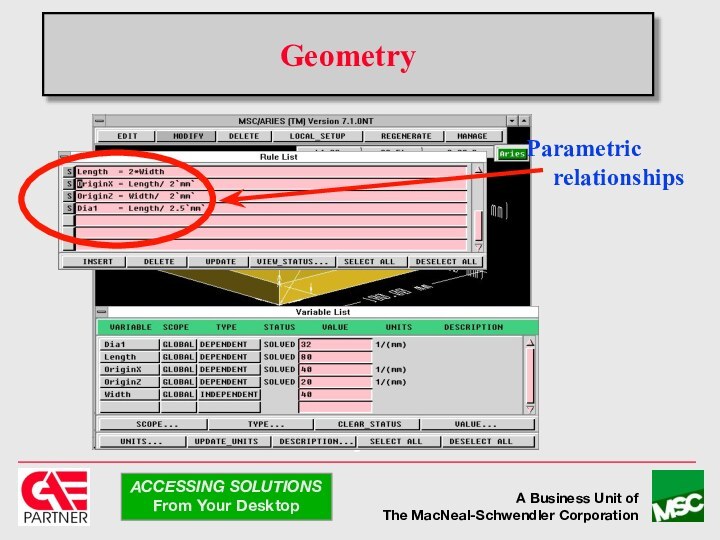

- 7. GeometryModification by dimensionParametric relationships

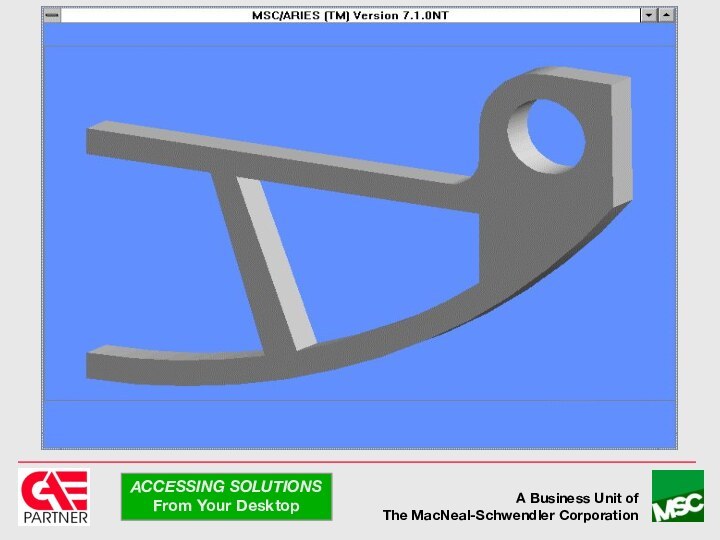

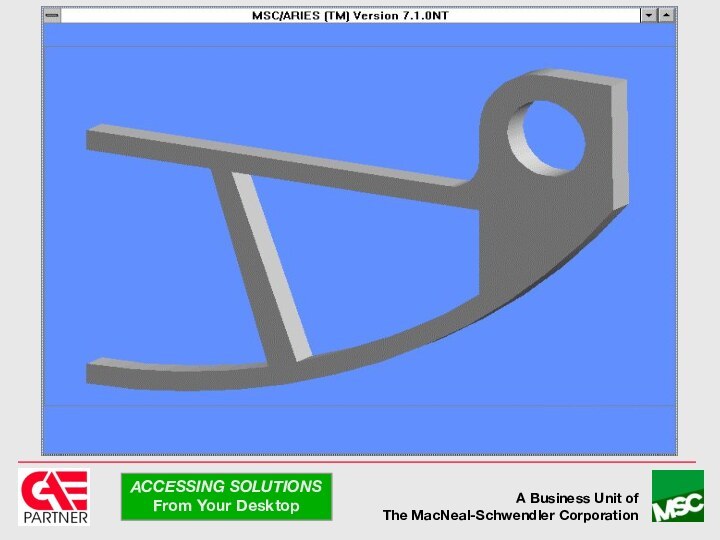

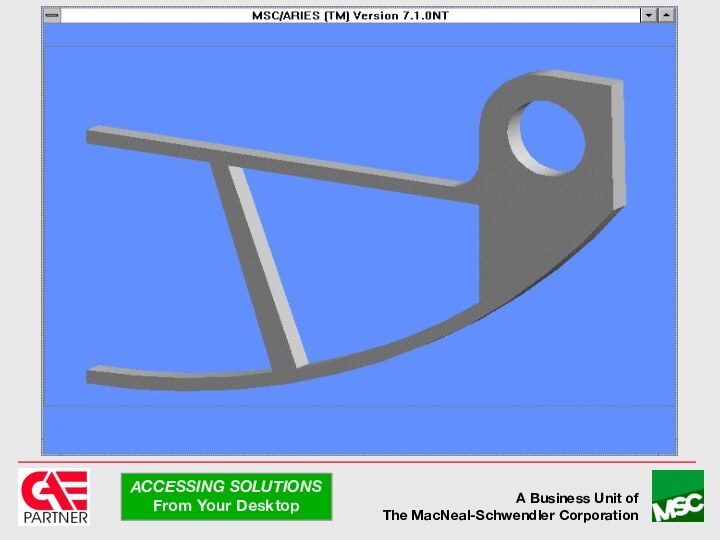

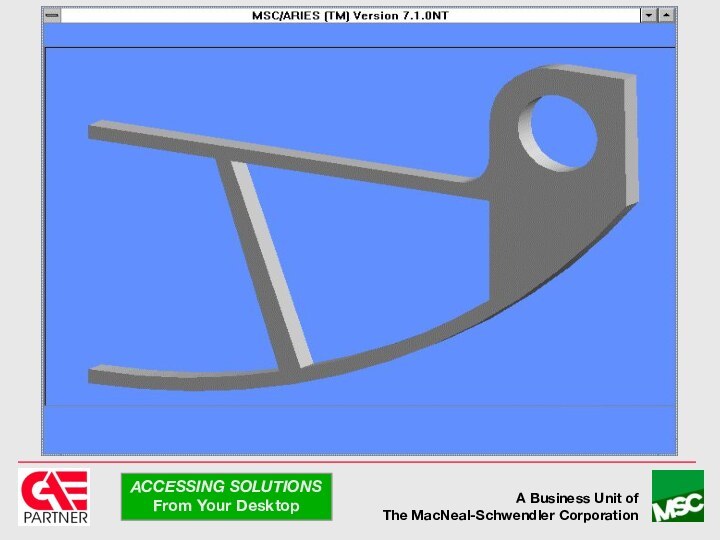

- 8. GeometryComplex solidsSkin operatorSweep operatorExtensive blending and chamferingRegion operator to sub-divide geometryMap meshingLoad footprint areasSymmetry

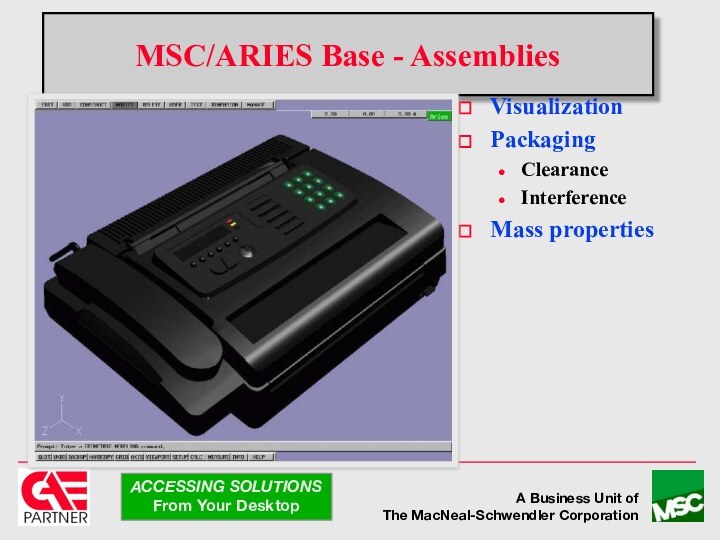

- 9. MSC/ARIES Base - AssembliesVisualizationPackagingClearance InterferenceMass properties

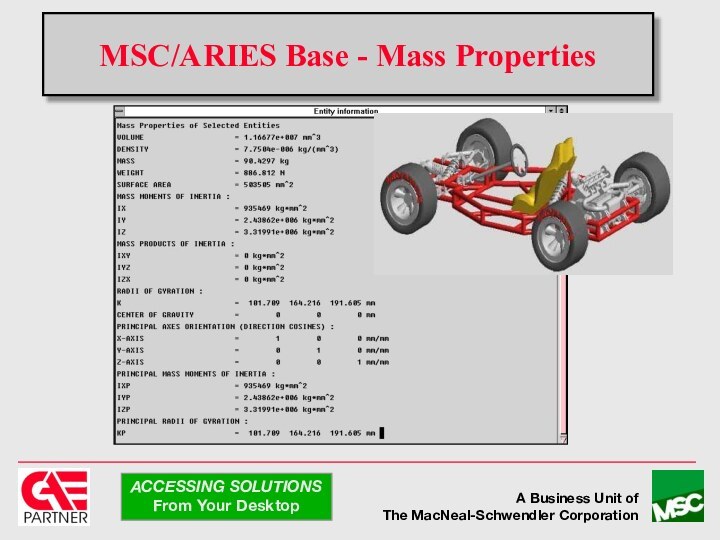

- 10. MSC/ARIES Base - Mass Properties

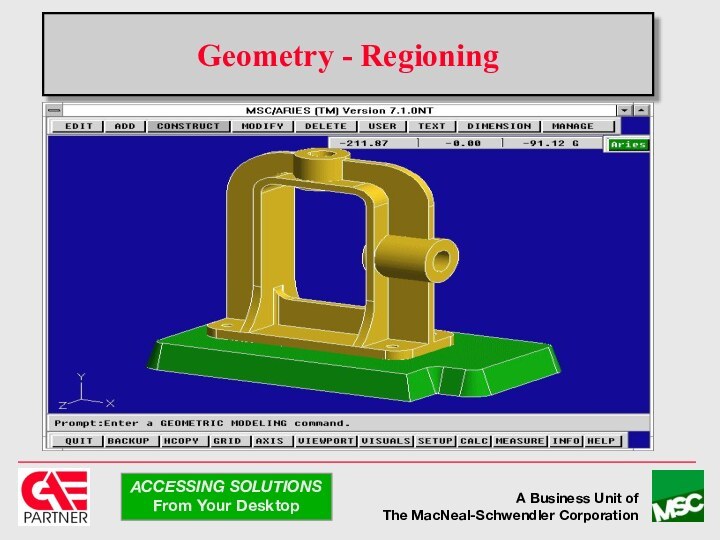

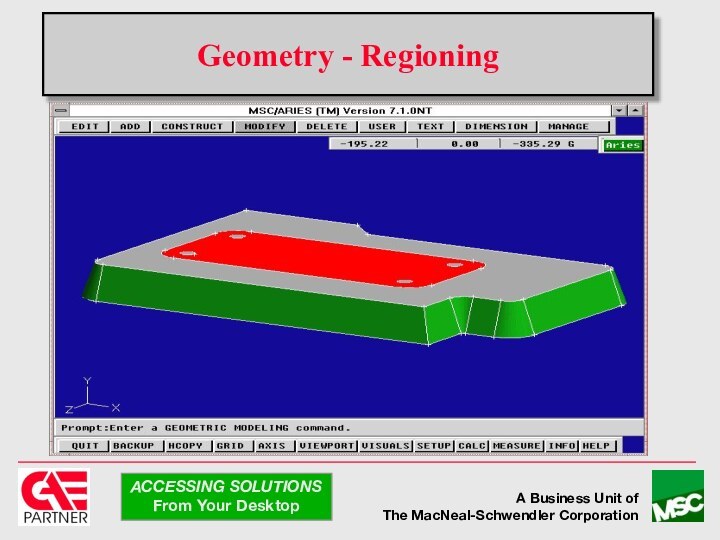

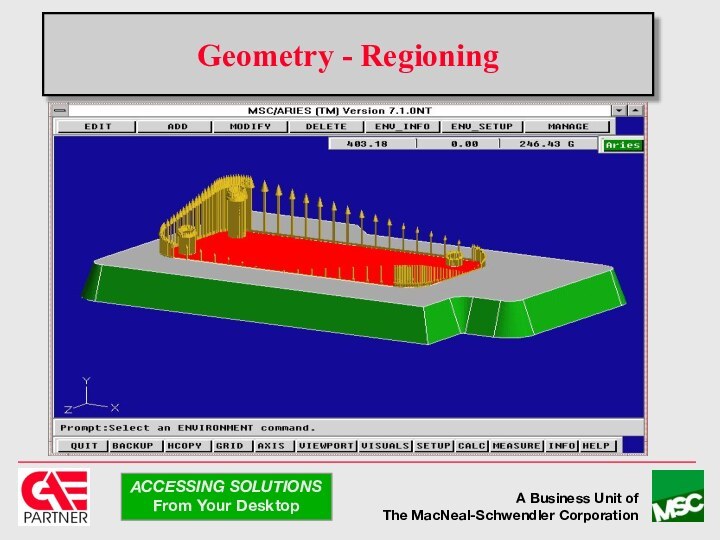

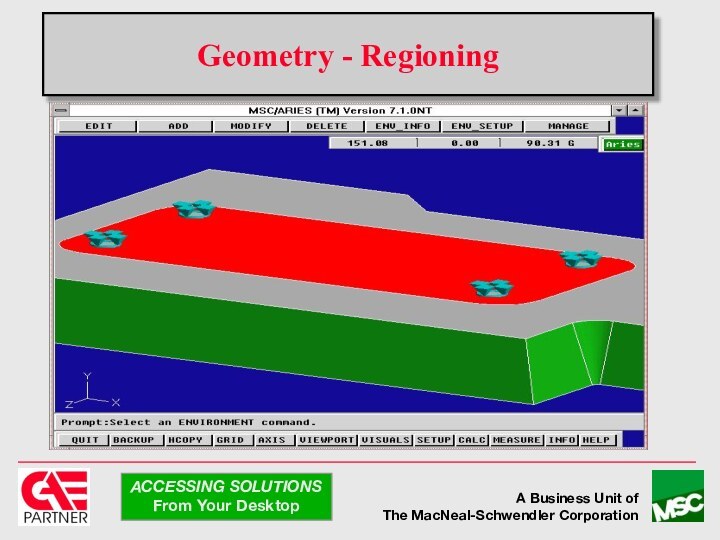

- 11. Geometry - Regioning

- 12. Geometry - Regioning

- 13. Geometry - Regioning

- 14. Geometry - Regioning

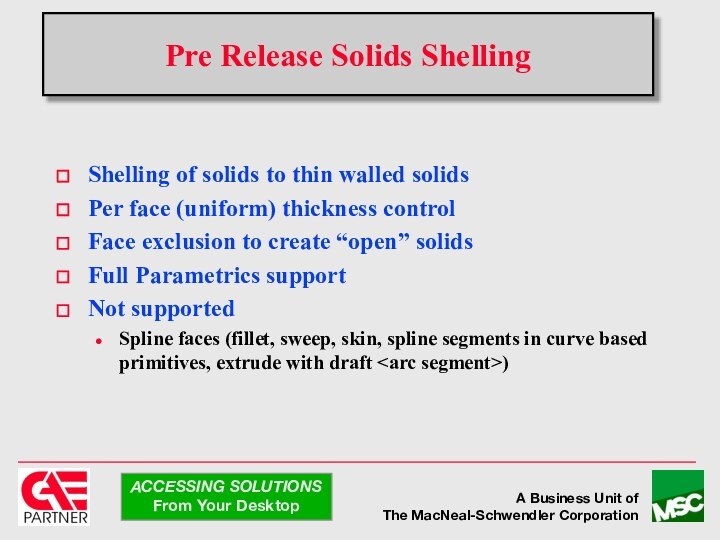

- 15. Pre Release Solids ShellingShelling of solids to

- 16. Analysis Of ACIS &Imported GeometryCADARIES

- 17. Geometry Interface - ACISSupport for ACIS sat

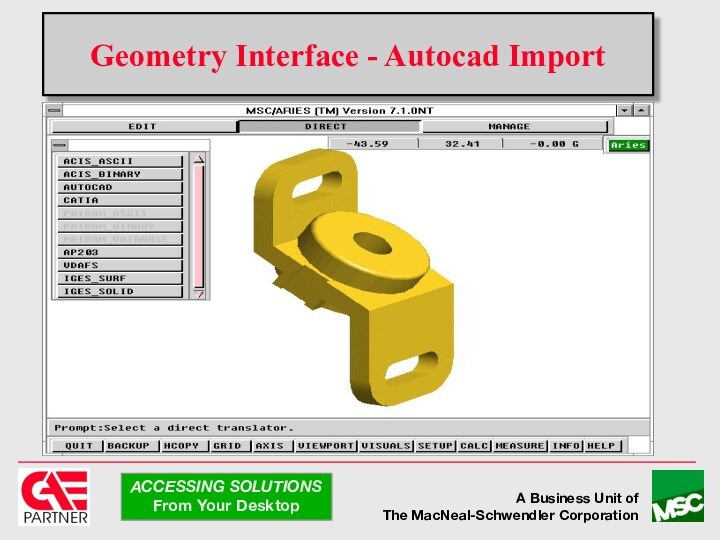

- 18. Geometry Interface - Autocad Import

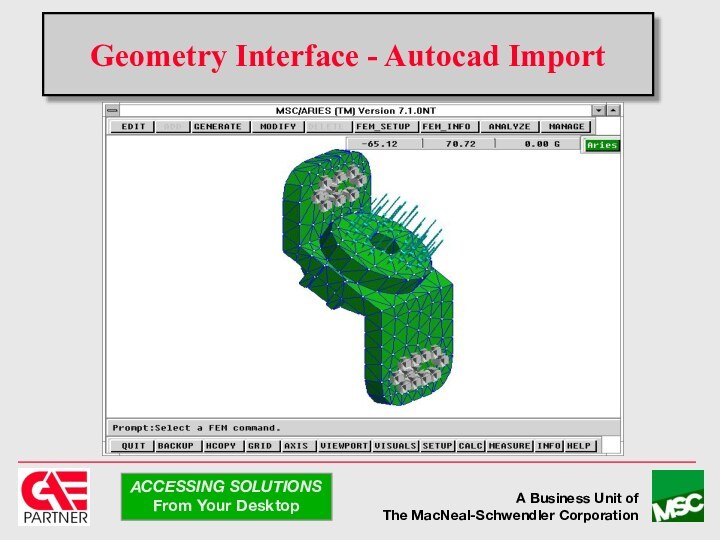

- 19. Geometry Interface - Autocad Import

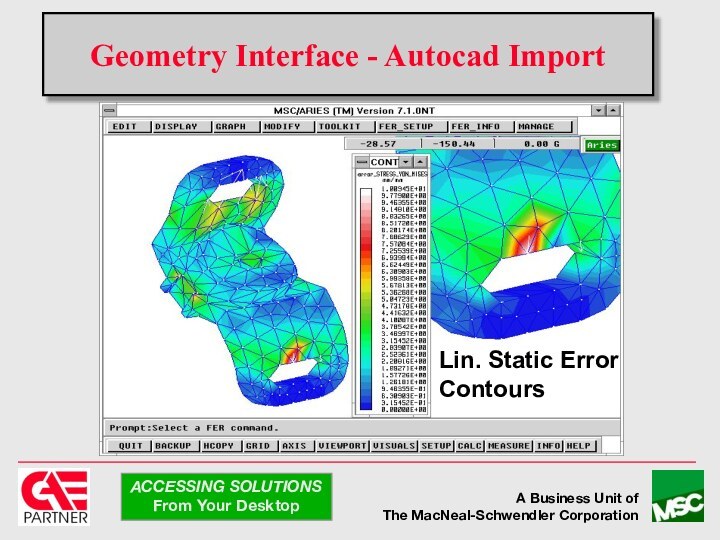

- 20. Geometry Interface - Autocad ImportLin. Static Error Contours

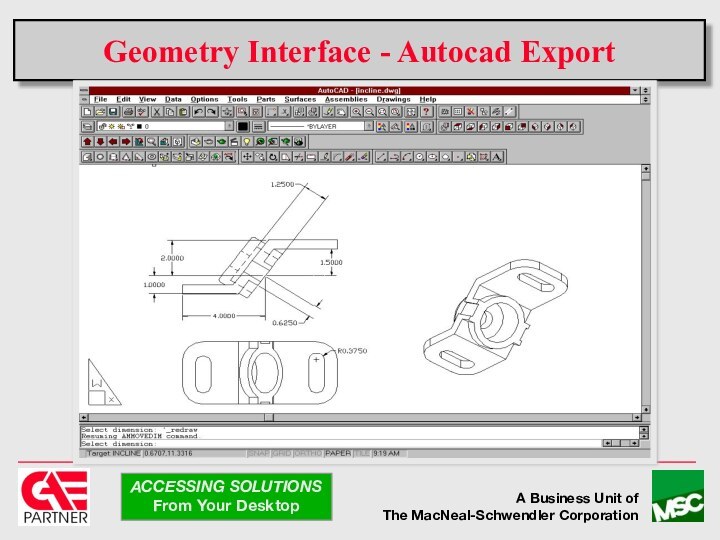

- 21. Geometry Interface - Autocad Export

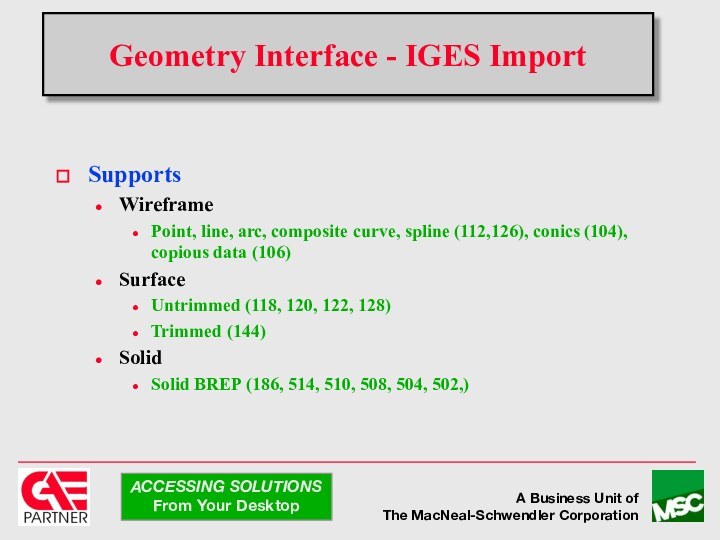

- 22. Geometry Interface - IGES ImportSupportsWireframe Point, line,

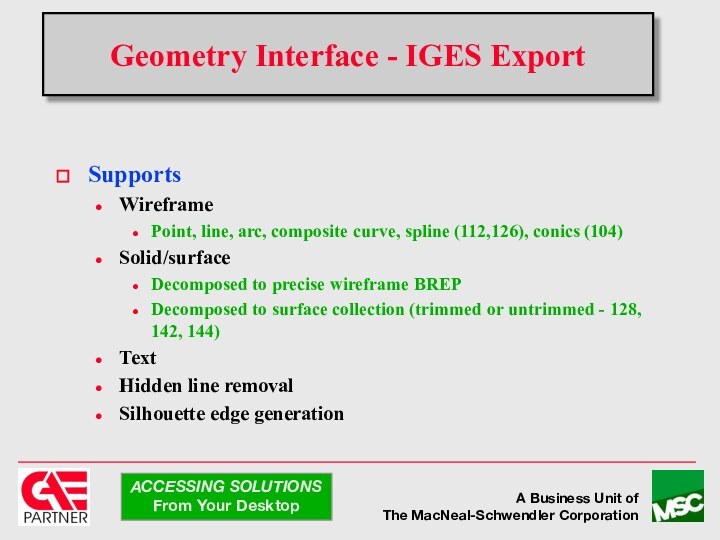

- 23. Geometry Interface - IGES ExportSupportsWireframe Point, line,

- 24. Geometry Interface - DXF ImportWireframePoint, line, arc, polylineText

- 25. Geometry Interface - DXF ExportSupportsWireframe Point, line,

- 26. Geometry Interfaces - STEP, VDAFSPDES/STEP AP203Import and

- 27. Geometry Interfaces -StereolithographyTranslates solids into standard “stl” formatRapid manufacture for physical part prototyping

- 28. GeometryFE AnalysisOptimizationMechanismsPlasticsMSC/ARIES Positioning

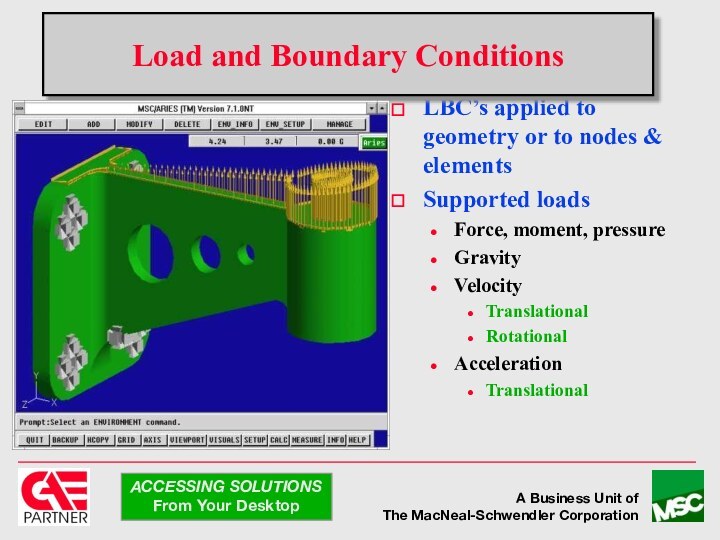

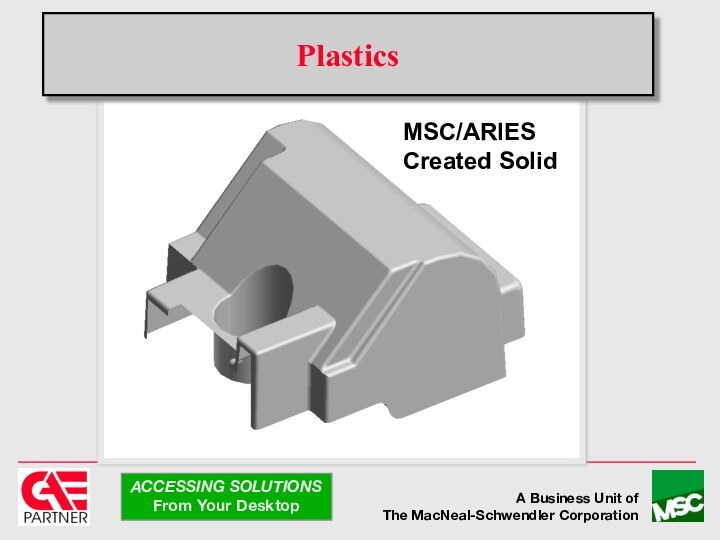

- 29. LBC’s applied to geometry or to nodes

- 30. Constant or functional varying magnitude Geometry based

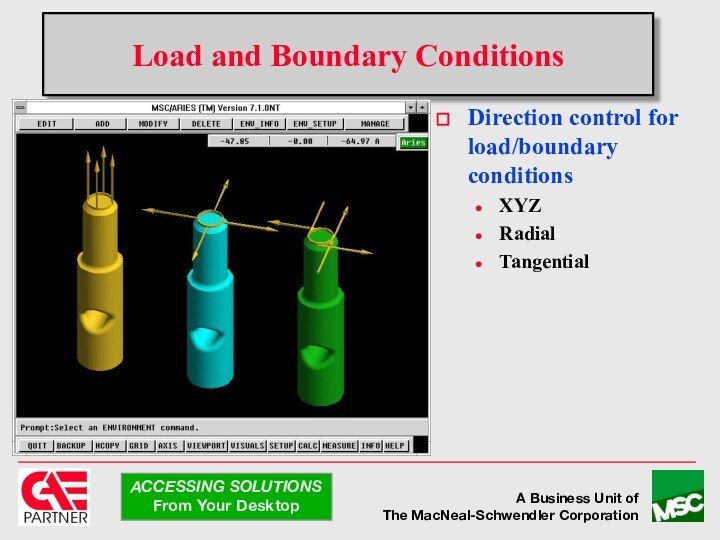

- 31. Load and Boundary ConditionsDirection control for load/boundary conditionsXYZRadialTangential

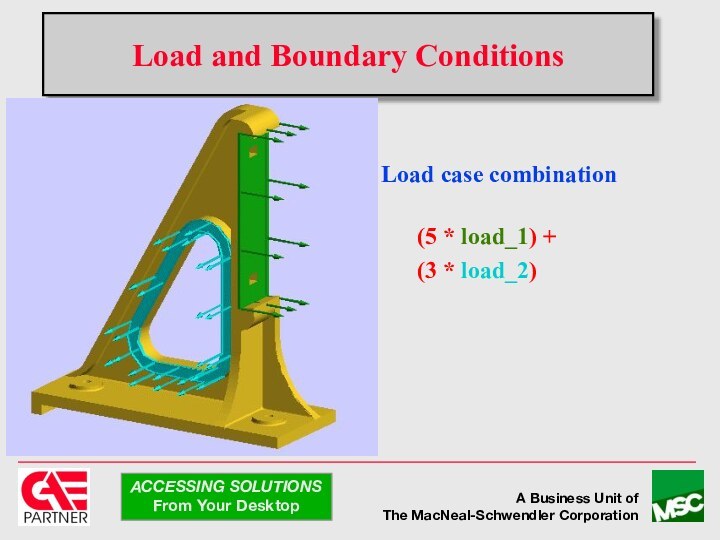

- 32. Load and Boundary ConditionsLoad case combination (5 * load_1) + (3 * load_2)

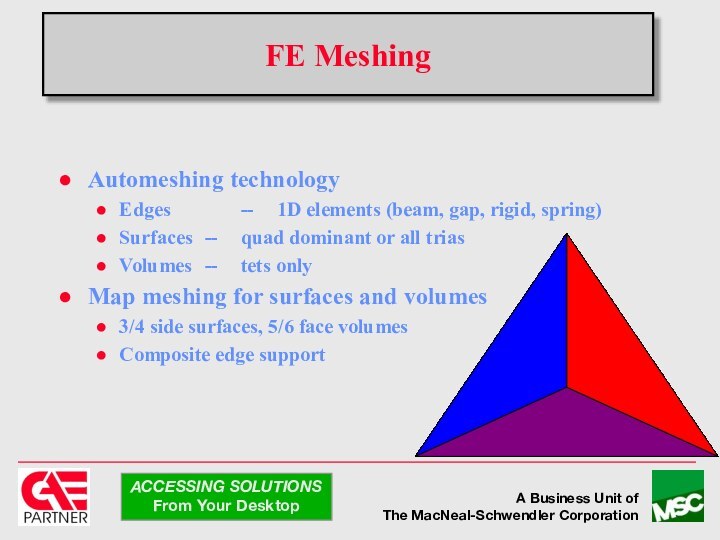

- 33. Automeshing technologyEdges -- 1D elements (beam, gap, rigid, spring)Surfaces -- quad

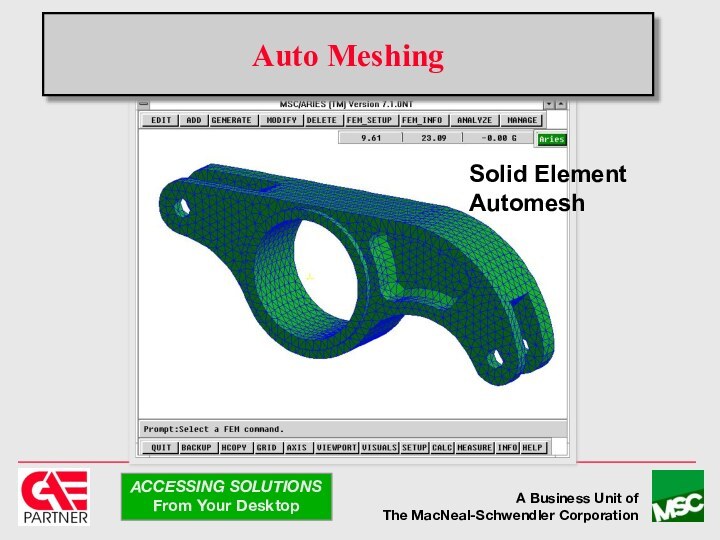

- 34. Auto MeshingSolid Element Automesh

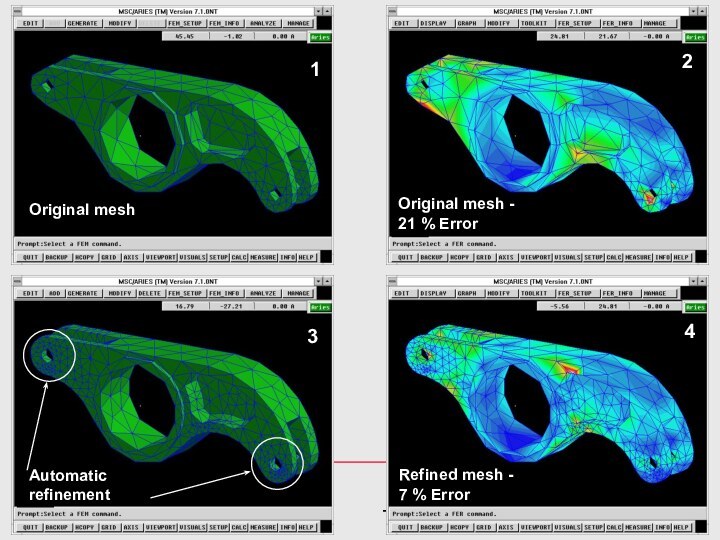

- 35. FE MeshingAdaptive mesh refinementAutomatic mesh refinement to

- 36. Original mesh -

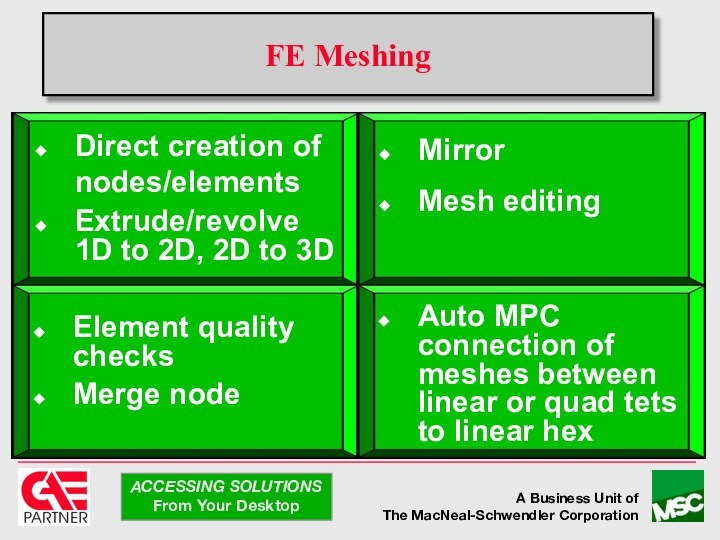

- 37. FE MeshingDirect creation of nodes/elementsExtrude/revolve 1D to

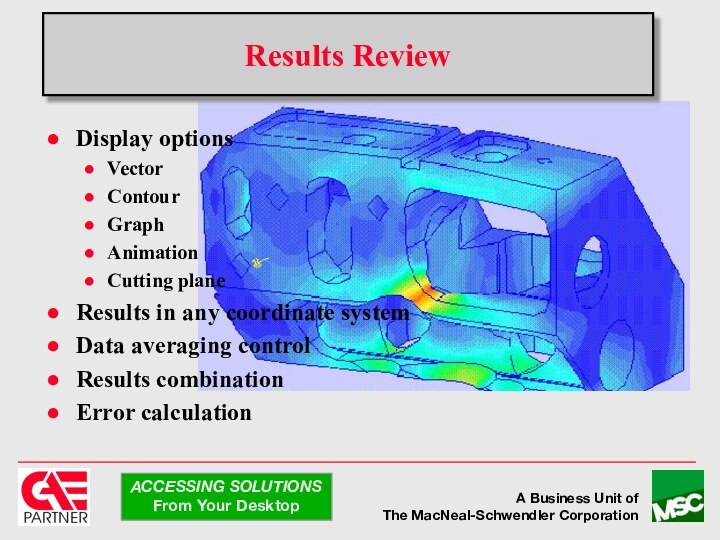

- 38. Display optionsVectorContourGraphAnimationCutting planeResults in any coordinate systemData averaging controlResults combinationError calculationResults Review

- 39. Linear StaticsLoads constant with timeMaterial assumed linear and perfectly elasticResults calculatedStressDisplacementStrainStrain energyReaction force

- 40. Normal ModesCalculates undamped natural modes of vibrationMaterial assumed linear and perfectly elasticResults calculated (normalized)StressDisplacementStrainStrain energyReaction force

- 41. Linear BucklingCalculates load factor for critical bucklingMaterial assumed linear and perfectly elasticResults calculatedStressDisplacementStrainStrain energyReaction force

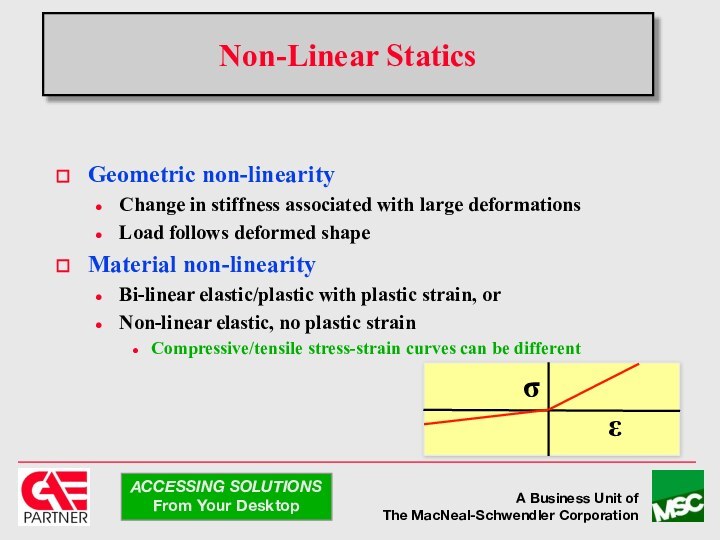

- 42. Non-Linear StaticsGeometric non-linearityChange in stiffness associated with

- 43. Non-Linear StaticsNon-linear Elastic Material

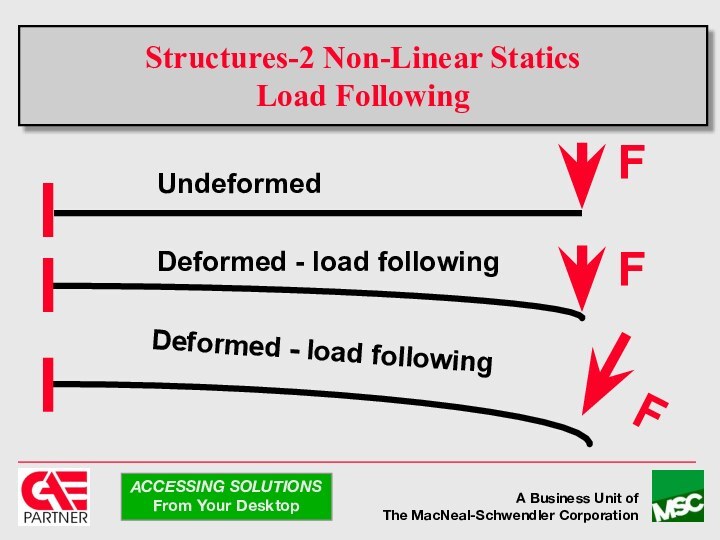

- 44. Structures-2 Non-Linear Statics Load FollowingDeformed - load followingDeformed - load followingFFFUndeformed

- 45. Linear Transient DynamicsTime varying geometry and finite

- 46. Heat TransferSteady state and transient linear and

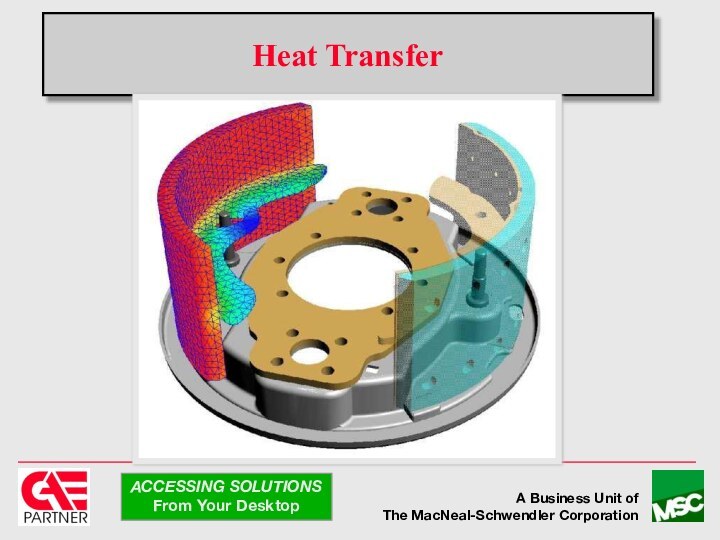

- 47. Heat Transfer

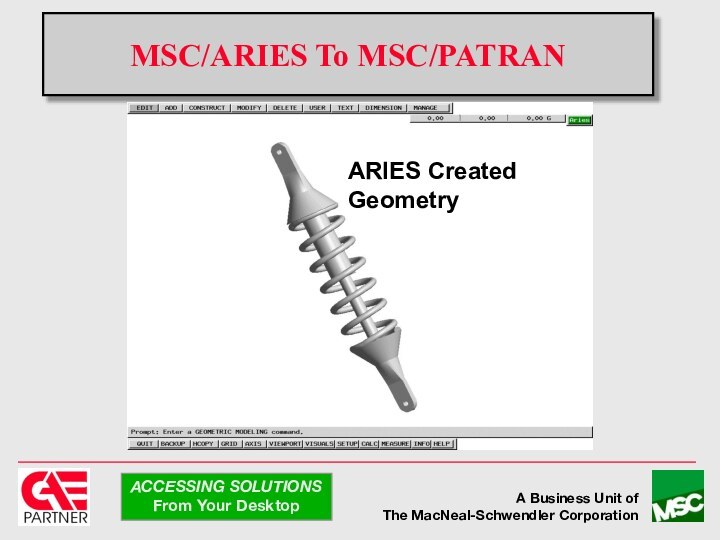

- 48. MSC/ARIES To MSC/PATRANARIES Created Geometry

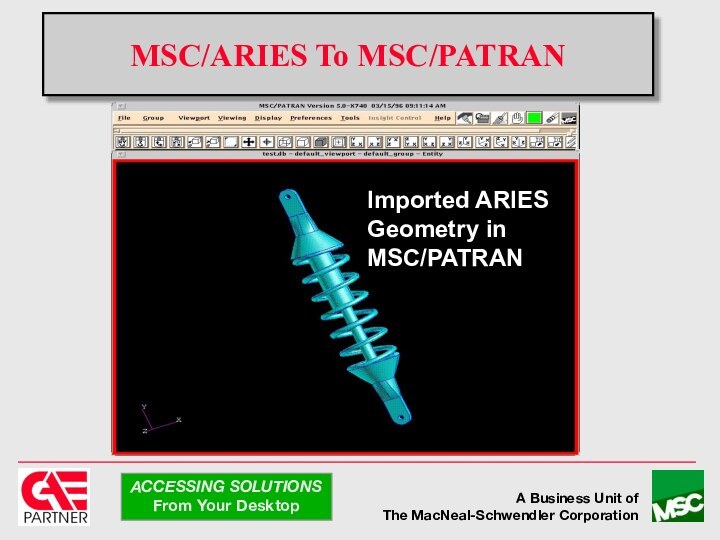

- 49. MSC/ARIES To MSC/PATRANImported ARIES Geometry in MSC/PATRAN

- 50. GeometryFE AnalysisOptimizationMechanismsPlasticsMSC/ARIES Positioning

- 51. OptimizationAn Automated Process That:Satisfies Your Design Objective Within Design Constraint(s) By Modifying Design Variables

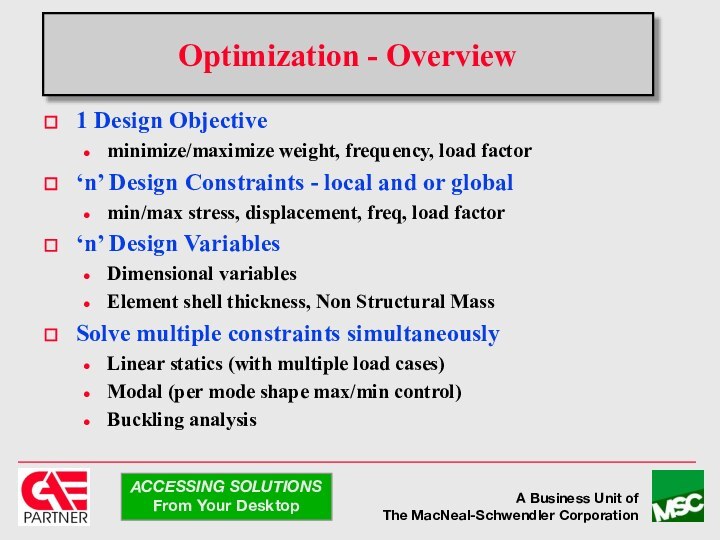

- 52. Optimization - Overview1 Design Objective minimize/maximize weight,

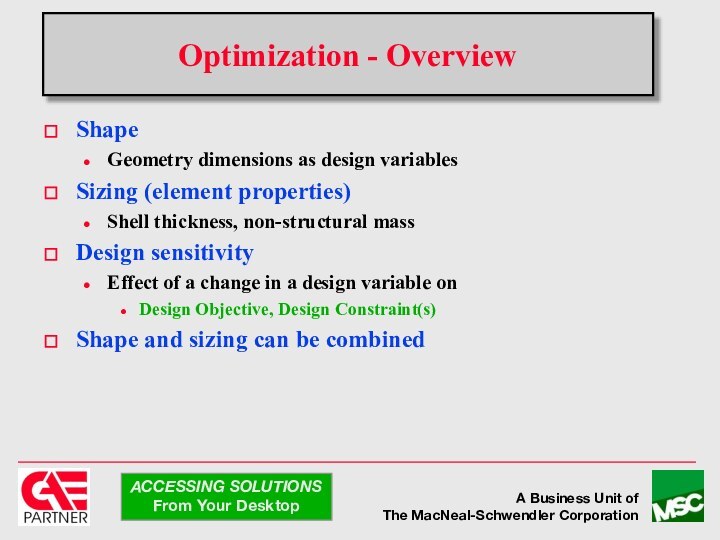

- 53. Optimization - OverviewShape Geometry dimensions as design

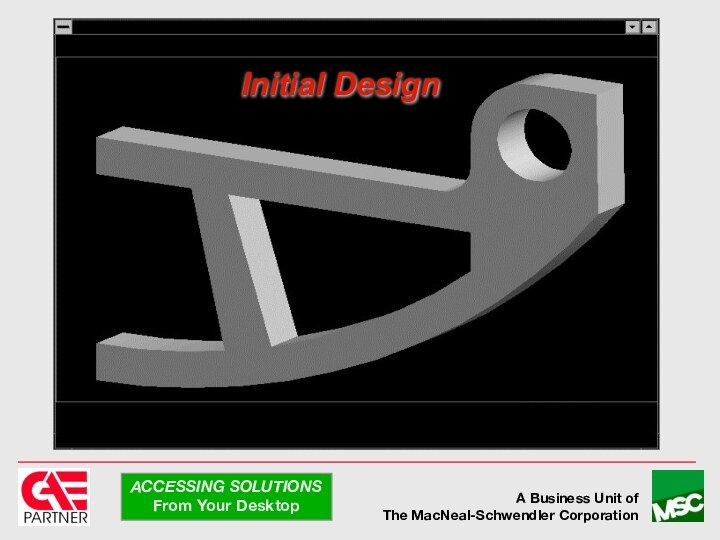

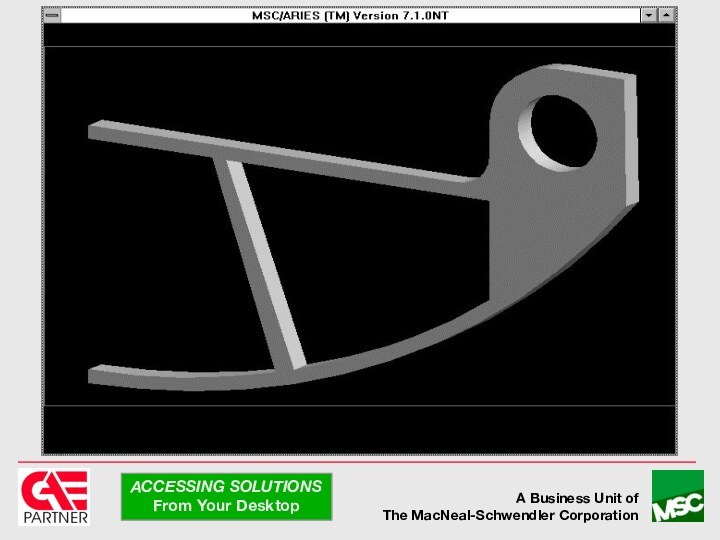

- 54. Initial Design

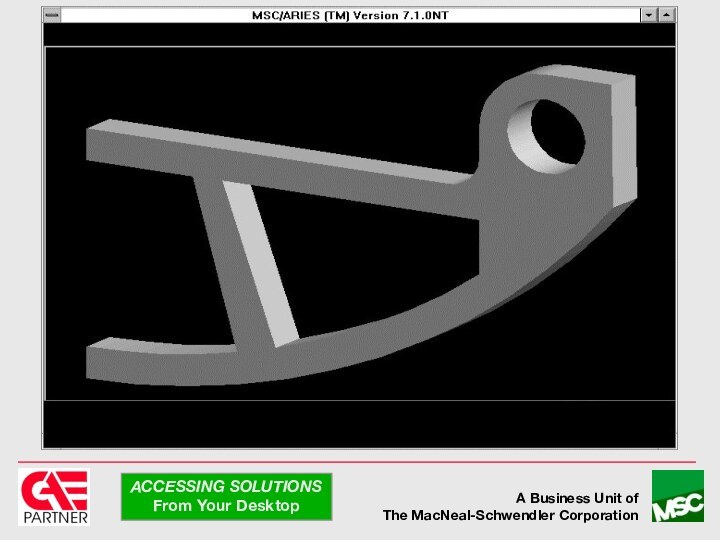

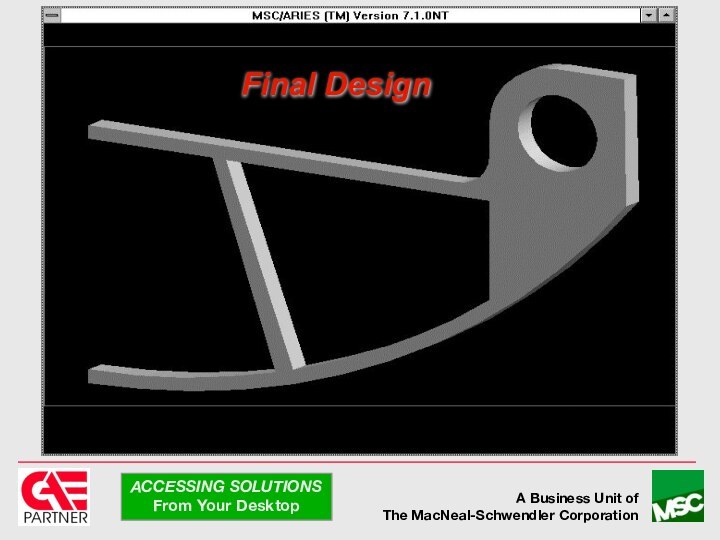

- 61. Final Design

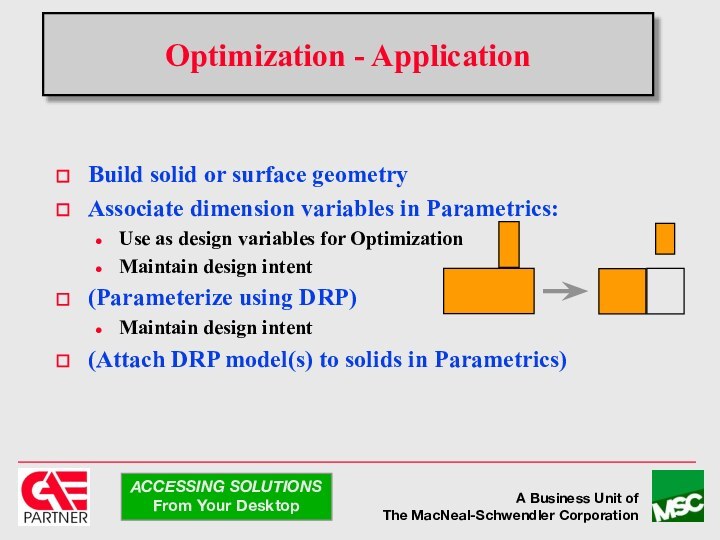

- 62. Optimization - ApplicationBuild solid or surface geometryAssociate

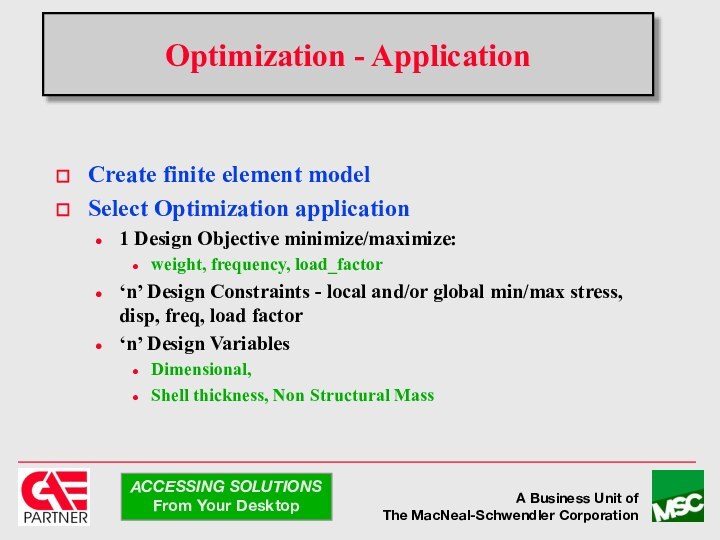

- 63. Optimization - ApplicationCreate finite element modelSelect Optimization

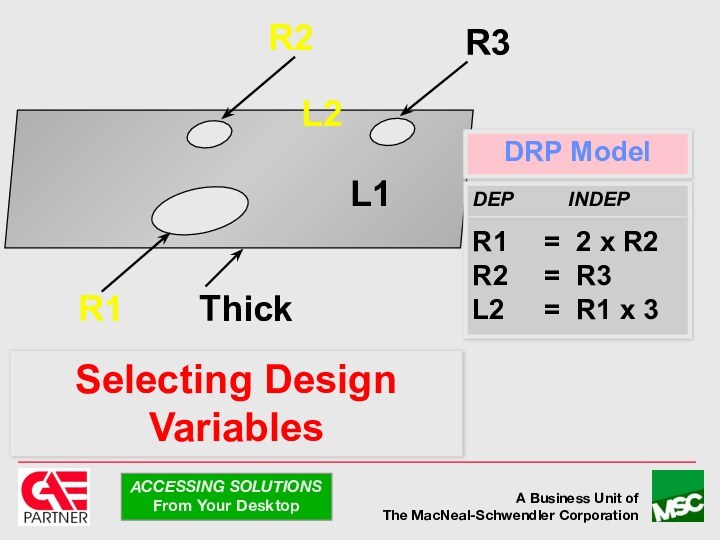

- 64. R1L2L1R3R2DEP INDEPR1

- 65. Optimization - Results ReviewPost process in Optimization

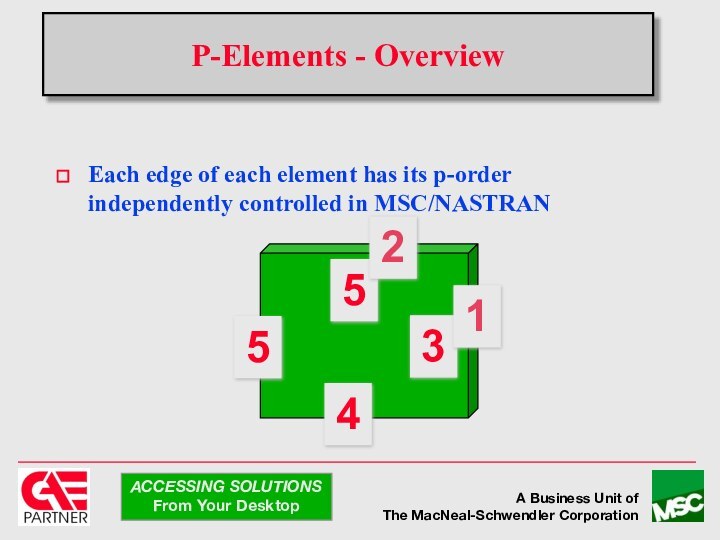

- 67. P-Elements - OverviewAutomatically increases element’s shape function

- 68. P-Elements - OverviewEach edge of each element has its p-order independently controlled in MSC/NASTRAN552314

- 69. P-Elements - ApplicationSupported element typesTetrahedronBrickPentahedron (wedge)p-order min/max

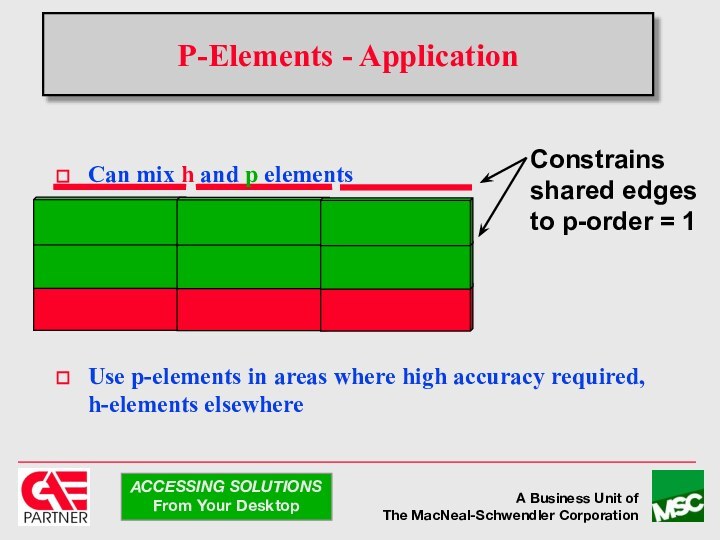

- 70. P-Elements - ApplicationConstrains shared edges to

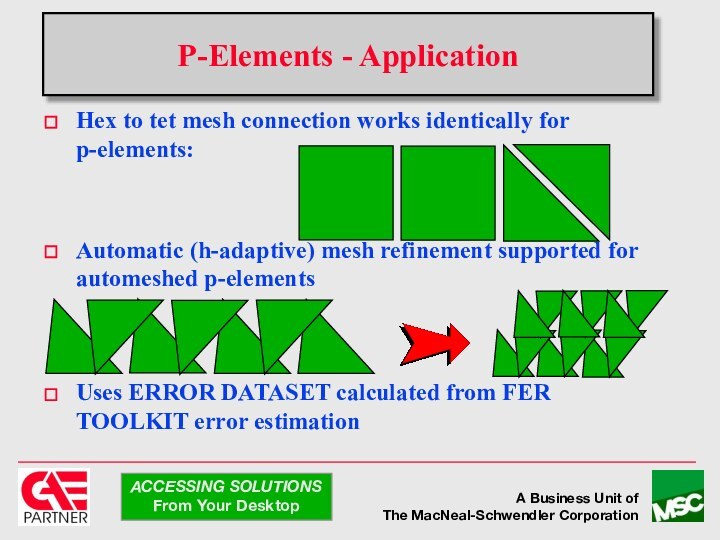

- 71. P-Elements - ApplicationHex to tet mesh connection

- 72. P-Elements - Results Reviewp-element results review identical to h-elementsCan display final p element order contours

- 73. GeometryFE AnalysisOptimizationMechanismsPlasticsMSC/ARIES Positioning

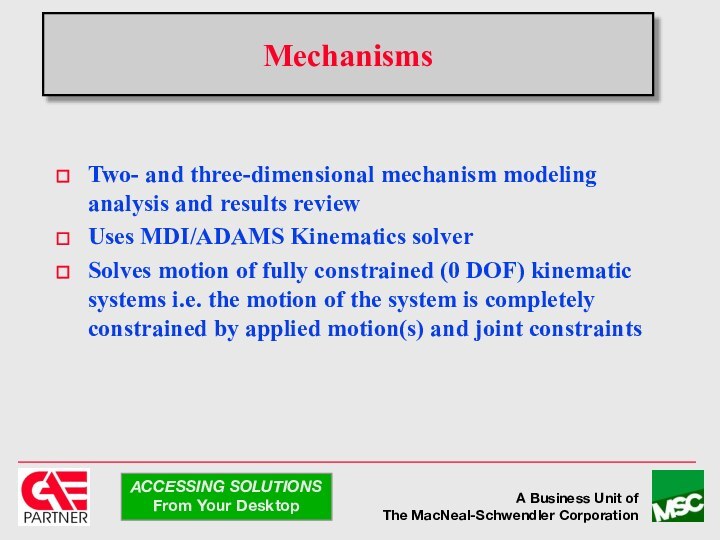

- 74. Two- and three-dimensional mechanism modeling analysis and

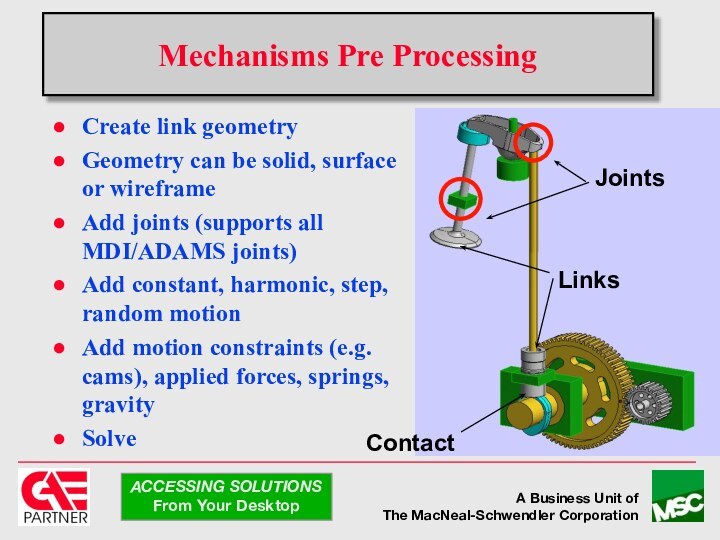

- 75. Create link geometryGeometry can be solid, surface

- 76. Mechanisms Results ReviewAnimated motion of linksMotion path

- 77. GeometryFE AnalysisOptimizationMechanismsPlasticsMSC/ARIES Positioning

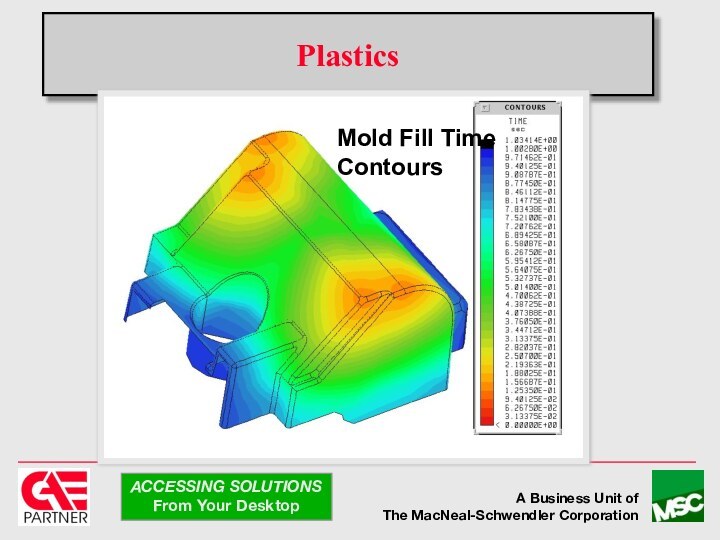

- 78. Plastics3D mold fill analysisUses Moldflow/Flowcheck solverSolves “Will

- 79. PlasticsMSC/ARIES Created Solid

- 80. PlasticsMold Fill Time Contours

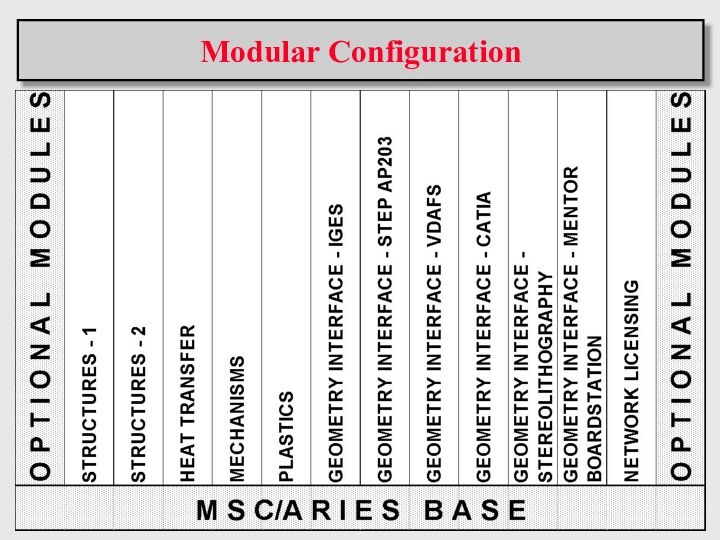

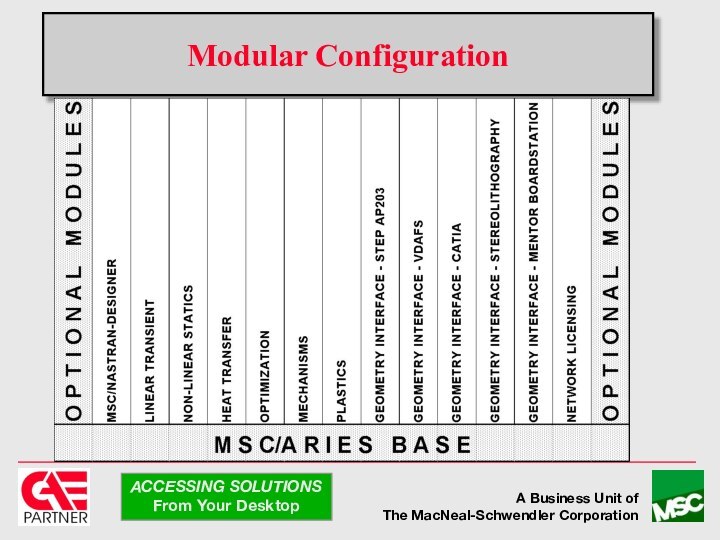

- 82. Modular Configuration

- 83. Modular Configuration

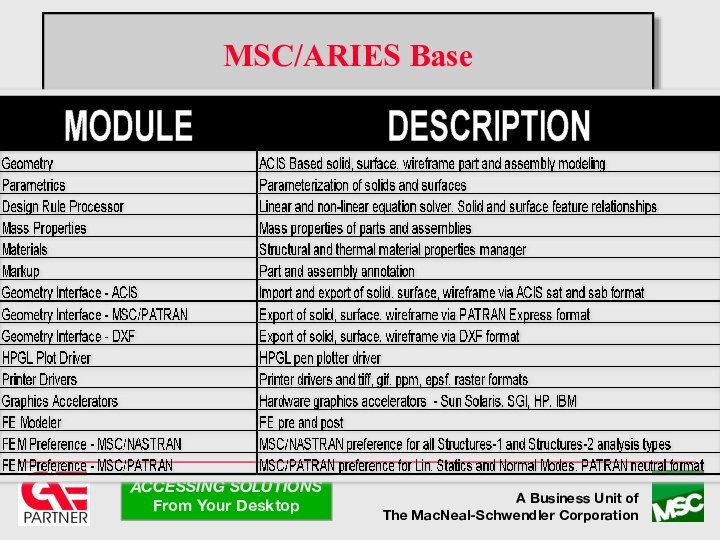

- 84. MSC/ARIES Base

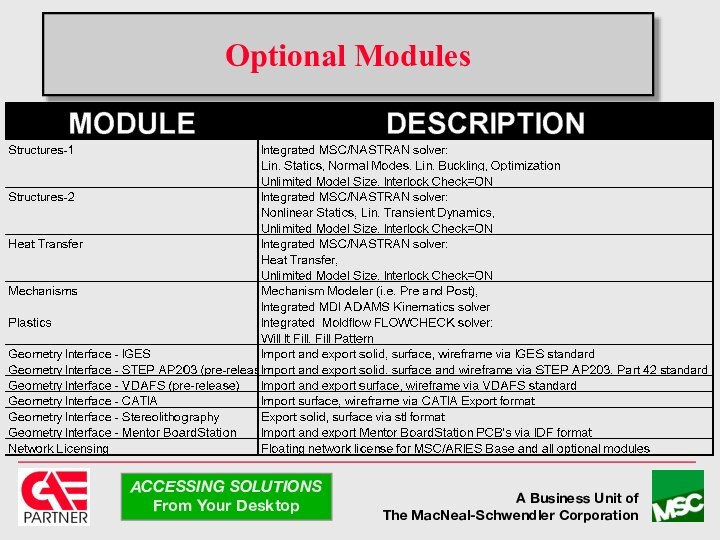

- 85. Optional Modules

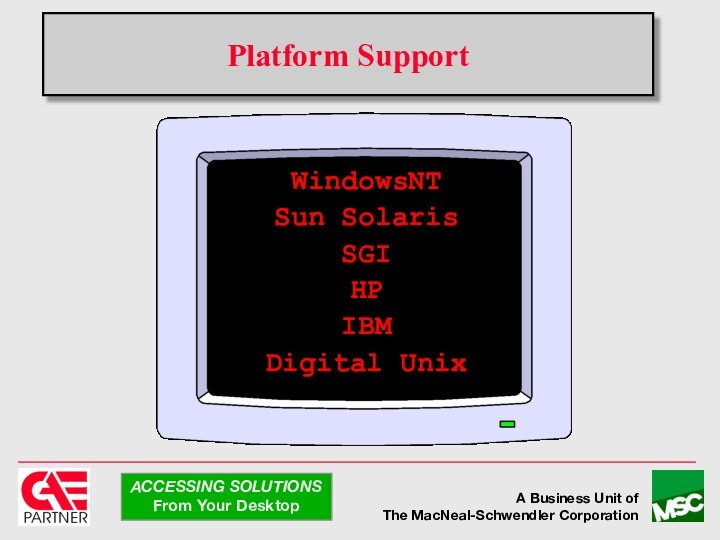

- 86. Platform Support WindowsNTSun SolarisSGIHPIBMDigital Unix

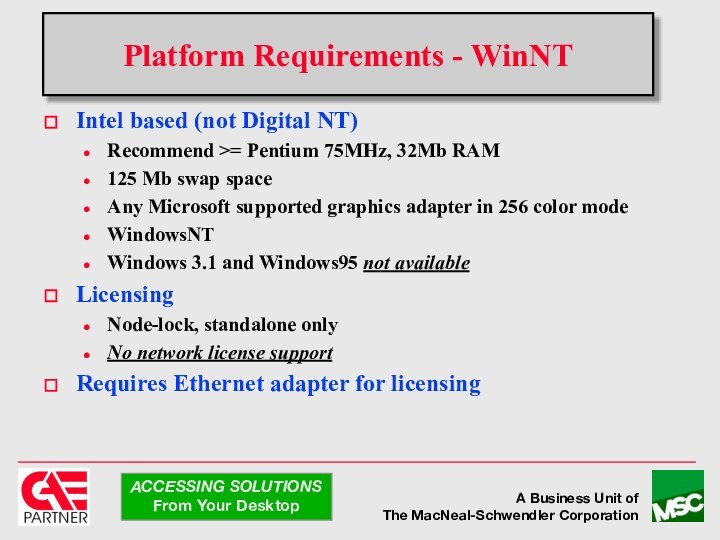

- 87. Intel based (not Digital NT)Recommend >= Pentium

- 88. Supported Unix workstation32Mb RAM125 Mb swap spaceLicensingNode-lock, andFloating network licensePlatform Requirements - Unix

- 89. GeometryFE AnalysisOptimizationMechanismsPlasticsMSC/ARIES Positioning

- 90. MSC/ARIES PositioningStandalone Design and Analysis SystemDesigned and

- 91. StructuralThermalMechanismsPlastic Molding AnalysisMSC/ARIES Positioning

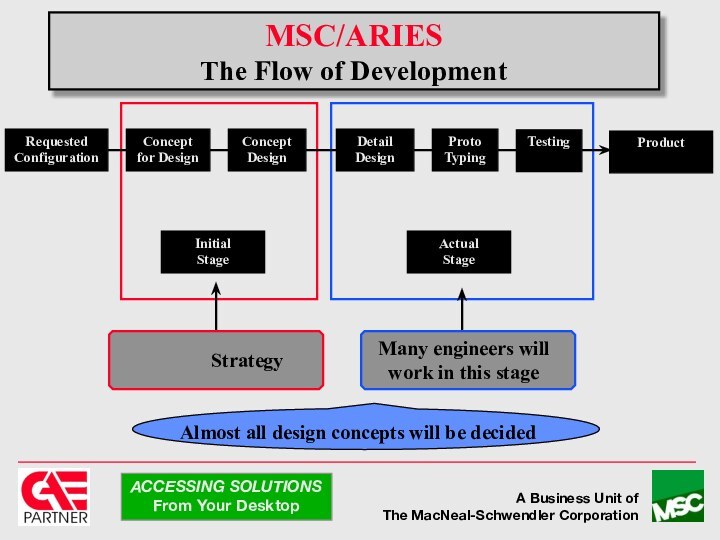

- 92. MSC/ARIES The Flow of DevelopmentProductAlmost all design concepts will be decided

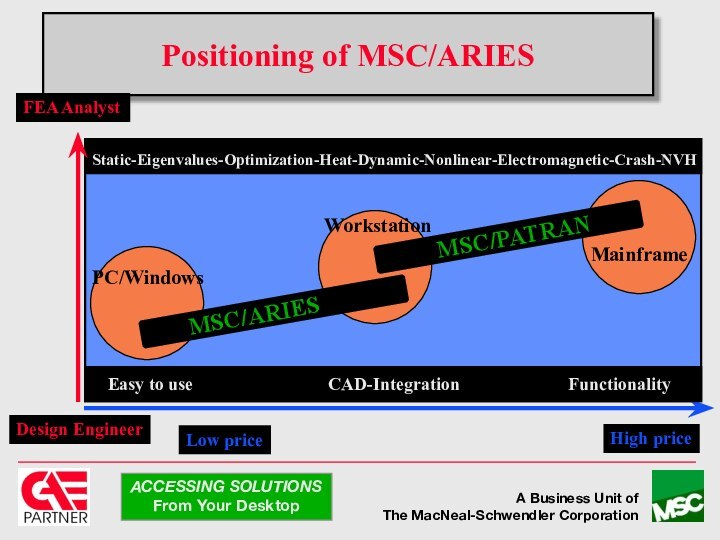

- 93. Positioning of MSC/ARIESFEA AnalystDesign EngineerLow priceHigh priceStatic-Eigenvalues-Optimization-Heat-Dynamic-Nonlinear-Electromagnetic-Crash-NVHEasy

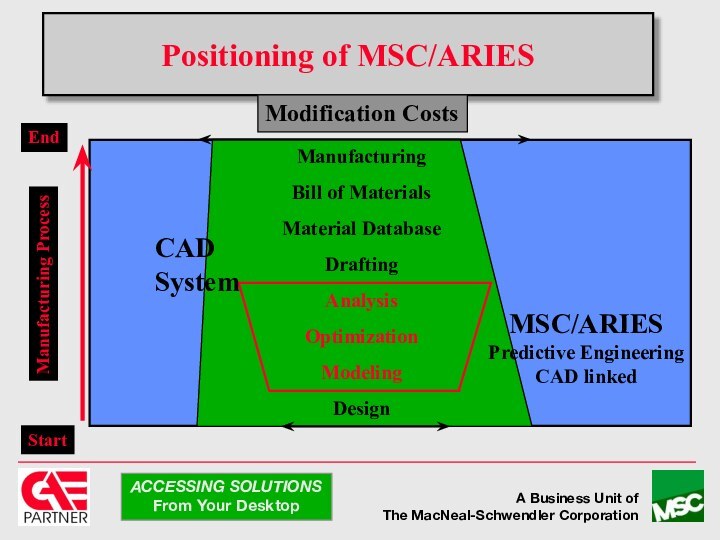

- 94. Positioning of MSC/ARIESEndStartManufacturing ProcessManufacturingBill of MaterialsMaterial DatabaseDraftingAnalysisOptimizationModelingDesignMSC/ARIESPredictive EngineeringCAD linkedCAD SystemModification Costs

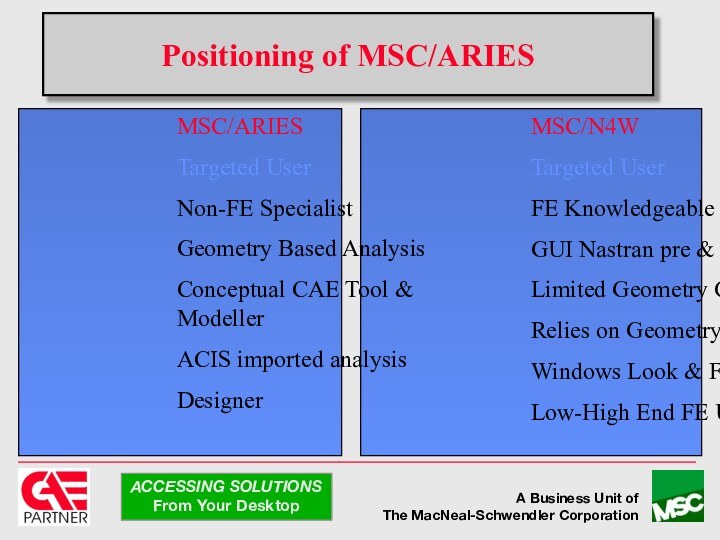

- 95. Positioning of MSC/ARIESMSC/ARIESTargeted UserNon-FE SpecialistGeometry Based AnalysisConceptual

- 96. Positioning of MSC/ARIESGuide line thought / Question ProcessCAD SystemImport GeometryCreateGeometryFEAwareN4WARIESPoss.No SaleConflict WithExistingModellerNeed ToCreateDrawingsACIS DraftingPackage (AutoCAD etc)NOYes

- 97. THE END

- 98. Mentor BoardStation InterfaceBi-directional interface using Mentor IDF

- 99. Скачать презентацию

- 100. Похожие презентации

Bob Gilliver MSC/ARIES European Product Marketing and Support Manager

Слайд 8

Geometry

Complex solids

Skin operator

Sweep operator

Extensive blending and chamfering

Region operator

to sub-divide geometry

Map meshing

Load footprint areas

Symmetry

Слайд 15

Pre Release Solids Shelling

Shelling of solids to thin

walled solids

Per face (uniform) thickness control

Face exclusion to create

“open” solidsFull Parametrics support

Not supported

Spline faces (fillet, sweep, skin, spline segments in curve based primitives, extrude with draft

Слайд 17

Geometry Interface - ACIS

Support for ACIS sat (ASCII)

and sab (binary) file formats

Allows bi-directional exchange of solids,

surface and wireframeCurrently the most reliable solids data exchange format

Transfers geometry only

No feature or history information

Слайд 22

Geometry Interface - IGES Import

Supports

Wireframe

Point, line, arc,

composite curve, spline (112,126), conics (104), copious data (106)

Surface

Untrimmed

(118, 120, 122, 128)Trimmed (144)

Solid

Solid BREP (186, 514, 510, 508, 504, 502,)

Слайд 23

Geometry Interface - IGES Export

Supports

Wireframe

Point, line, arc,

composite curve, spline (112,126), conics (104)

Solid/surface

Decomposed to precise wireframe

BREP Decomposed to surface collection (trimmed or untrimmed - 128, 142, 144)

Text

Hidden line removal

Silhouette edge generation

Слайд 25

Geometry Interface - DXF Export

Supports

Wireframe

Point, line, arc,

composite curve, spline

Solid/surface

Decomposed to precise wireframe BREP

Text

Hidden line

removalSilhouette edge generation

Слайд 26

Geometry Interfaces - STEP, VDAFS

PDES/STEP AP203

Import and export

of solid/surface/wireframe data

VDAFS

Import and export of surface/wireframe data

Data format

that emphasizes surface transferUsed predominantly by European automotive industry

Слайд 27

Geometry Interfaces -Stereolithography

Translates solids into standard “stl” format

Rapid

manufacture for physical part prototyping

Слайд 29

LBC’s applied to geometry or to nodes &

elements

Supported loads

Force, moment, pressure

Gravity

Velocity

Translational

Rotational

Acceleration

Translational

Load and Boundary Conditions

Слайд 30

Constant or functional varying magnitude

Geometry based load

and boundary conditions survive geometry change

Load and Boundary Conditions

Слайд 31

Load and Boundary Conditions

Direction control for load/boundary conditions

XYZ

Radial

Tangential

Слайд 33

Automeshing technology

Edges -- 1D elements (beam, gap, rigid, spring)

Surfaces -- quad dominant

or all trias

Volumes -- tets only

Map meshing for surfaces and volumes

3/4

side surfaces, 5/6 face volumes Composite edge support

FE Meshing

Слайд 35

FE Meshing

Adaptive mesh refinement

Automatic mesh refinement to optimize

mesh density

Use with automatically generated h or p

meshesGlobal or local refinement

New mesh density based on current error versus target error

Reduces mesh density related errors

Слайд 37

FE Meshing

Direct creation of nodes/elements

Extrude/revolve 1D to 2D,

2D to 3D

Mirror

Mesh editing

Element quality checks

Merge node

Auto

MPC connection of meshes between linear or quad tets to linear hex

Слайд 38

Display options

Vector

Contour

Graph

Animation

Cutting plane

Results in any coordinate system

Data averaging

control

Results combination

Error calculation

Results Review

Слайд 39

Linear Statics

Loads constant with time

Material assumed linear and

perfectly elastic

Results calculated

Stress

Displacement

Strain

Strain energy

Reaction force

Слайд 40

Normal Modes

Calculates undamped natural modes of vibration

Material assumed

linear and perfectly elastic

Results calculated (normalized)

Stress

Displacement

Strain

Strain energy

Reaction force

Слайд 41

Linear Buckling

Calculates load factor for critical buckling

Material assumed

linear and perfectly elastic

Results calculated

Stress

Displacement

Strain

Strain energy

Reaction force

Слайд 42

Non-Linear Statics

Geometric non-linearity

Change in stiffness associated with large

deformations

Load follows deformed shape

Material non-linearity

Bi-linear elastic/plastic with plastic

strain, orNon-linear elastic, no plastic strain

Compressive/tensile stress-strain curves can be different

ε

σ

Слайд 44

Structures-2 Non-Linear Statics

Load Following

Deformed - load following

Deformed -

load following

F

F

F

Undeformed

Слайд 45

Linear Transient Dynamics

Time varying geometry and finite element

loads

Structural and modal damping

Results calculated for each time step

Stress

Displacement

Strain

Velocity

Acceleration

Reaction

force

Слайд 46

Heat Transfer

Steady state and transient linear and non-linear

heat transfer

Heat transfer modes

Conduction

Free convection

Forced convection

Radiation

Temperature and time dependent

Heat flux

Mass flow rate

Слайд 51

Optimization

An Automated Process That:

Satisfies Your Design Objective

Within

Design Constraint(s)

By Modifying Design Variables

Слайд 52

Optimization - Overview

1 Design Objective

minimize/maximize weight, frequency,

load factor

‘n’ Design Constraints - local and or global

min/max

stress, displacement, freq, load factor‘n’ Design Variables

Dimensional variables

Element shell thickness, Non Structural Mass

Solve multiple constraints simultaneously

Linear statics (with multiple load cases)

Modal (per mode shape max/min control)

Buckling analysis

Слайд 53

Optimization - Overview

Shape

Geometry dimensions as design variables

Sizing

(element properties)

Shell thickness, non-structural mass

Design sensitivity

Effect of a

change in a design variable onDesign Objective, Design Constraint(s)

Shape and sizing can be combined

Слайд 62

Optimization - Application

Build solid or surface geometry

Associate dimension

variables in Parametrics:

Use as design variables for Optimization

Maintain

design intent(Parameterize using DRP)

Maintain design intent

(Attach DRP model(s) to solids in Parametrics)

Слайд 63

Optimization - Application

Create finite element model

Select Optimization application

1

Design Objective minimize/maximize:

weight, frequency, load_factor

‘n’ Design Constraints - local

and/or global min/max stress, disp, freq, load factor‘n’ Design Variables

Dimensional,

Shell thickness, Non Structural Mass

Слайд 65

Optimization - Results Review

Post process in Optimization application

Graph

design objective/ constraint(s)/ variable(s) against design cycle

Display geometry at

intermediate design cyclesReview results of final design in FE_Results

Standard results review process

Animate between FEmodels across design cycles

Слайд 67

P-Elements - Overview

Automatically increases element’s shape function polynomial

order during solution until convergence

Convergence based on per element

strain energy difference between p-order changesMesh remains unchanged

Слайд 68

P-Elements - Overview

Each edge of each element has

its p-order independently controlled in MSC/NASTRAN

5

5

2

3

1

4

Слайд 69

P-Elements - Application

Supported element types

Tetrahedron

Brick

Pentahedron (wedge)

p-order min/max control

Recommended

p-order range 3-10

Adaptivity automatically turns off below specified von

Mises stress or strain minimumTurns off adaptivity for elements where stress and or strain is negligible

Reduces CPU time and system resources

Слайд 70

P-Elements - Application

Constrains shared edges to p-order

= 1

Can mix h and p elements

Use p-elements in

areas where high accuracy required, h-elements elsewhere

Слайд 71

P-Elements - Application

Hex to tet mesh connection works

identically for p-elements:

Automatic (h-adaptive) mesh refinement supported for

automeshed p-elementsUses ERROR DATASET calculated from FER TOOLKIT error estimation

Слайд 72

P-Elements - Results Review

p-element results review identical to

h-elements

Can display final p element order contours

Слайд 74

Two- and three-dimensional mechanism modeling analysis and results

review

Uses MDI/ADAMS Kinematics solver

Solves motion of fully constrained

(0 DOF) kinematic systems i.e. the motion of the system is completely constrained by applied motion(s) and joint constraints Mechanisms

Слайд 75

Create link geometry

Geometry can be solid, surface or

wireframe

Add joints (supports all MDI/ADAMS joints)

Add constant, harmonic, step,

random motionAdd motion constraints (e.g. cams), applied forces, springs, gravity

Solve

Mechanisms Pre Processing

Links

Joints

Contact

Слайд 76

Mechanisms Results Review

Animated motion of links

Motion path of

any point

Joint reaction force/moment

Rotational/translational link displacement, velocity, acceleration

Clearance/interference between

linksResults interrogation in local static/dynamic coordinate system

Слайд 78

Plastics

3D mold fill analysis

Uses Moldflow/Flowcheck solver

Solves “Will It

Fill”

Fast analysis to calculate areas of

fill / no-fill /

possible fillExperiment with number of injection points/ location, material and part thickness

Solves “Fill_Pattern”

Fill time

Air trap location

Weld line locations

Слайд 87

Intel based (not Digital NT)

Recommend >= Pentium 75MHz,

32Mb RAM

125 Mb swap space

Any Microsoft supported graphics adapter

in 256 color modeWindowsNT

Windows 3.1 and Windows95 not available

Licensing

Node-lock, standalone only

No network license support

Requires Ethernet adapter for licensing

Platform Requirements - WinNT

Слайд 88

Supported Unix workstation

32Mb RAM

125 Mb swap space

Licensing

Node-lock, and

Floating

network license

Platform Requirements - Unix

Слайд 90

MSC/ARIES Positioning

Standalone Design and Analysis System

Designed and analyzed

in MSC/ARIES

Analysis of ACIS Based Geometry

Design built in CAD

systemDesign geometry import into MSC/ARIES

Analyzed in MSC/ARIES

Focus on Ease-of-Use and Automation For...

Слайд 93

Positioning of MSC/ARIES

FEA Analyst

Design Engineer

Low price

High price

Static-Eigenvalues-Optimization-Heat-Dynamic-Nonlinear-Electromagnetic-Crash-NVH

Easy to

use

CAD-Integration FunctionalityMSC/ARIES

MSC/PATRAN

PC/Windows

Workstation

Mainframe

Слайд 94

Positioning of MSC/ARIES

End

Start

Manufacturing Process

Manufacturing

Bill of Materials

Material Database

Drafting

Analysis

Optimization

Modeling

Design

MSC/ARIES

Predictive Engineering

CAD

linked

CAD

System

Modification Costs

Слайд 95

Positioning of MSC/ARIES

MSC/ARIES

Targeted User

Non-FE Specialist

Geometry Based Analysis

Conceptual CAE

Tool & Modeller

ACIS imported analysis

Designer

MSC/N4W

Targeted User

FE Knowledgeable

GUI Nastran

pre & postLimited Geometry Creation

Relies on Geometry Import

Windows Look & Feel

Low-High End FE User

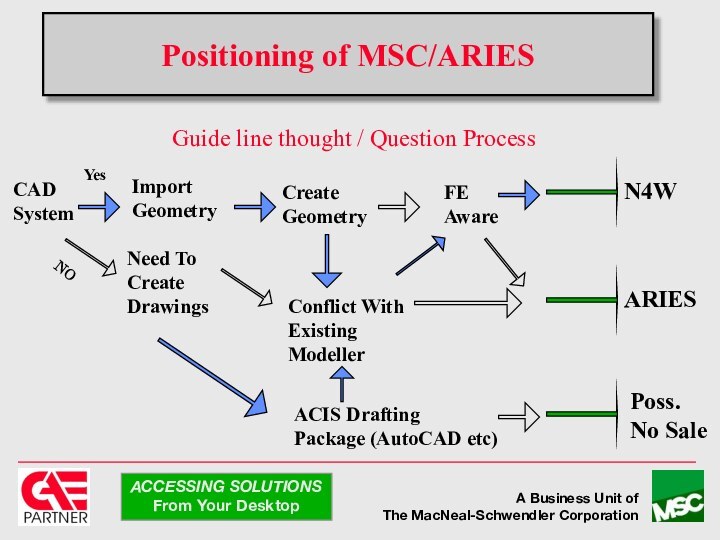

Слайд 96

Positioning of MSC/ARIES

Guide line thought / Question Process

CAD

System

Import

Geometry

Create

Geometry

FE

Aware

N4W

ARIES

Poss.

No Sale

Conflict With

Existing

Modeller

Need To

Create

Drawings

ACIS Drafting

Package (AutoCAD etc)

NO

Yes

Слайд 98

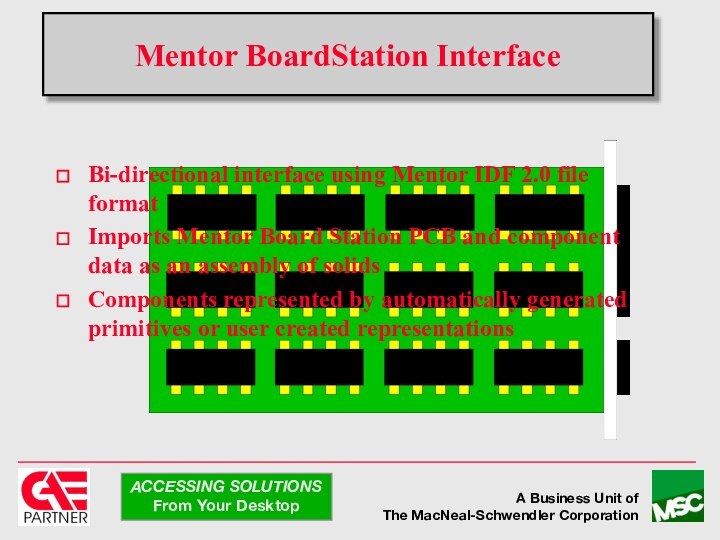

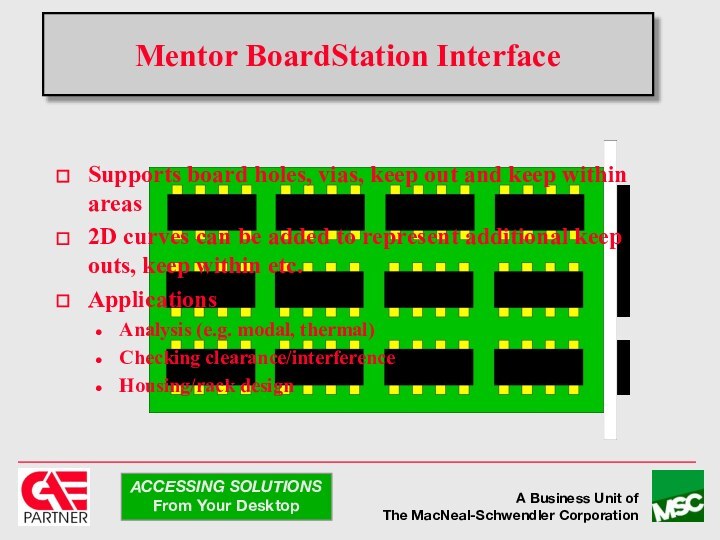

Mentor BoardStation Interface

Bi-directional interface using Mentor IDF 2.0

file format

Imports Mentor Board Station PCB and component data

as an assembly of solidsComponents represented by automatically generated primitives or user created representations