- Главная

- Разное

- Бизнес и предпринимательство

- Образование

- Развлечения

- Государство

- Спорт

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Религиоведение

- Черчение

- Физкультура

- ИЗО

- Психология

- Социология

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Что такое findslide.org?

FindSlide.org - это сайт презентаций, докладов, шаблонов в формате PowerPoint.

Обратная связь

Email: Нажмите что бы посмотреть

Презентация на тему Drilling methods

Содержание

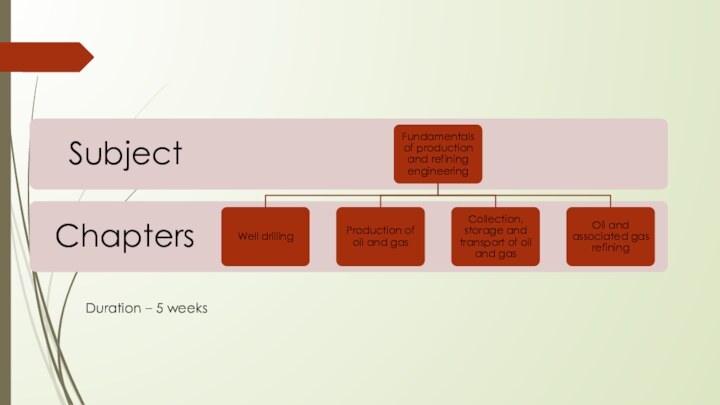

- 2. Duration – 5 weeks

- 3. Drilling methodsAuger drilling for construction purposes, environmental and geotechnical drilling, sampling

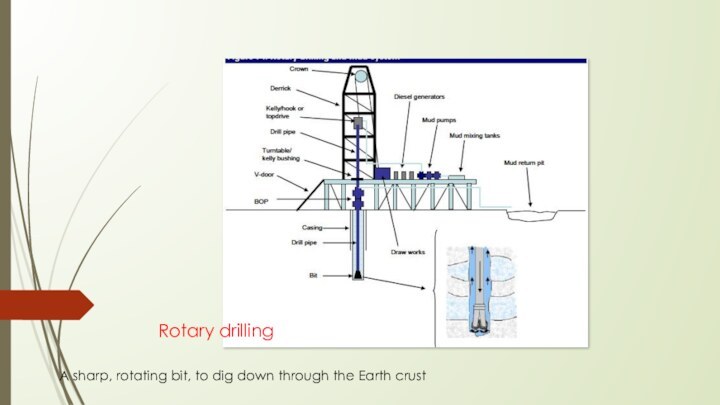

- 4. Rotary drilling A sharp, rotating bit, to dig down through the Earth crust

- 5. Before drilling commences, certain other arrangements and

- 6. Site preparationThe rig location and the road

- 7. This is usually a metre in depth

- 8. The next step is to set up

- 9. Wildcat: Speculative exploration well drilled in search of

- 10. Скачать презентацию

- 11. Похожие презентации

Duration – 5 weeks

Слайд 3

Drilling methods

Auger drilling for construction purposes, environmental and

geotechnical drilling, sampling

Слайд 5

Before drilling commences, certain other arrangements and decisions

have to be made. These may include:

Leasing of the

land - A mineral lease is a contract between the exploration company and land owner. In this case operating company will pay to land owner royalties. The payment of royalties begins with the first production and it is around 1/8 of the production, in some cases might be as high as 1/5 of the production

Слайд 6

Site preparation

The rig location and the road to

the lease will be surveyed and prepared. The drilling

lease must be large enough to accommodate the drilling rig, field offices, living quarters if it is an isolated location, drilling supplies and space for any service company equipment or vehicles.A normal drilling lease is 106 x 106 metres (348 x 348 feet) or 1.12 hectares (2.78 acres). Depending on the size of the drilling rig the lease may be as little as half an acre (0.20 hectares). In remote locations, an air strip and a separate area for a camp may also be required.

The lease should be cleaned from soil. Soil must be removed and set aside the lease. If the soil is consolidated.

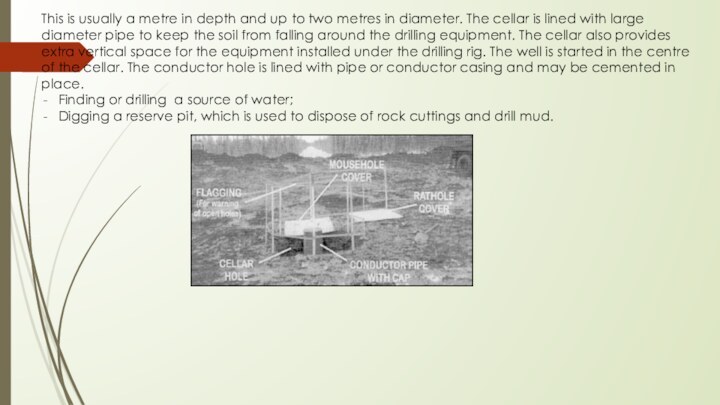

Once the lease is cleared a service a subcontractor or service company is hired to dig a pit or cellar.

Слайд 7 This is usually a metre in depth and

up to two metres in diameter. The cellar is

lined with large diameter pipe to keep the soil from falling around the drilling equipment. The cellar also provides extra vertical space for the equipment installed under the drilling rig. The well is started in the centre of the cellar. The conductor hole is lined with pipe or conductor casing and may be cemented in place.Finding or drilling a source of water;

Digging a reserve pit, which is used to dispose of rock cuttings and drill mud.

Слайд 8

The next step is to set up the

rig. Drilling occurs in stages:

A surface hole is drilled

to a depth between 60 and 400 metres, depending on underground aquifers and area conditions.The crew pulls out drill pipe, drill string and inserts stell pipe, is called surface casing, which is cemented in place to isolate the wellbore and geological formations.

The crew installs blowout preventers (BOP), specialized valves are used to seal and control the wells

Replacing a drilling bit. This process is called tripping.

Shallow wells today are drilled without bits. Instead of bits is used casing pipe.

Слайд 9 Wildcat: Speculative exploration well drilled in search of a

new oil or gas accumulation

Exploratory well: A hole drilled: a)

to find oil or gas in an area previously considered unproductive; b) to find a new reservoir in a known field, i.e., one previously producing oil and gas from another reservoir, or c) to extend the limit of a known oil or gas reservoirAppraisal Well: Well drilled after the discovery of oil or gas to establish the limits of the reservoir, the productivity of wells in it and the properties of the oil or gas

Development well: A well drilled within the proved area of an oil or gas reservoir to the depth of a stratigraphic horizon known to be productive