- Главная

- Разное

- Бизнес и предпринимательство

- Образование

- Развлечения

- Государство

- Спорт

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Религиоведение

- Черчение

- Физкультура

- ИЗО

- Психология

- Социология

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Что такое findslide.org?

FindSlide.org - это сайт презентаций, докладов, шаблонов в формате PowerPoint.

Обратная связь

Email: Нажмите что бы посмотреть

Презентация на тему Identification of Defects and Secondary Phases in Reactively Sputtered Cu2 ZnSnS4 Thin Films

Содержание

- 2. OutlineMotivationProblems with characterization of thin filmsExperimental approachResultsX-ray diffractionRaman SpectroscopyTransmission Electron MicroscopyScanning Auger MicroscopySummary & Acknowledgements

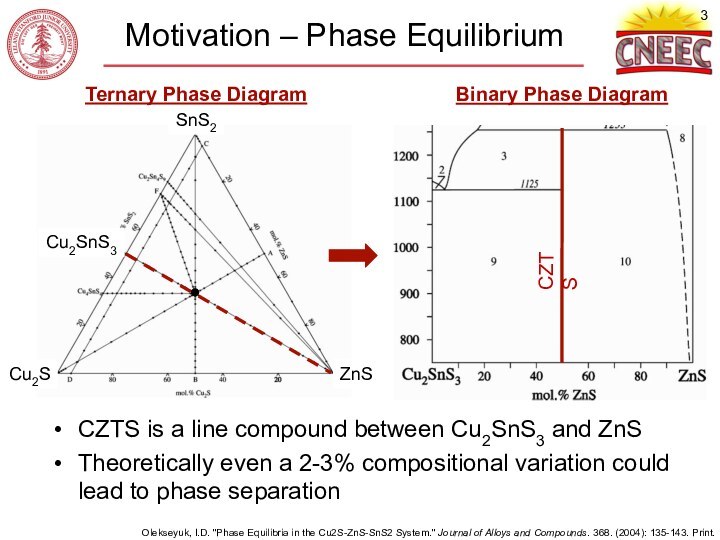

- 3. Motivation – Phase EquilibriumCZTS is a line

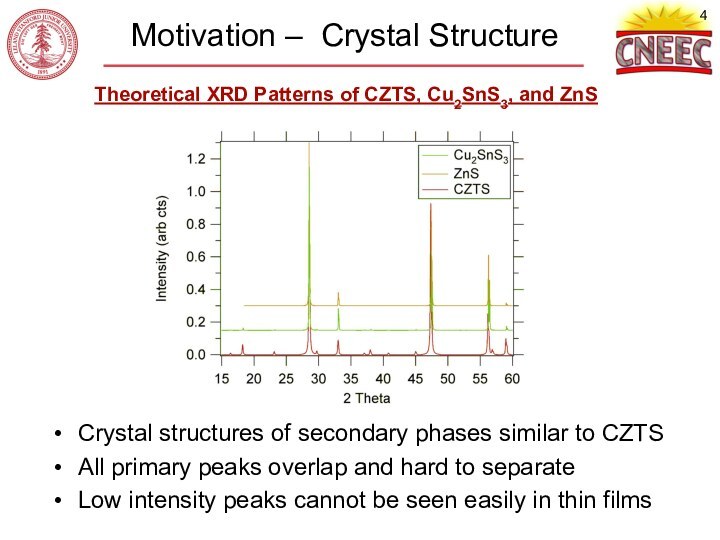

- 4. Motivation – Crystal StructureCrystal structures of secondary

- 5. Experimental ApproachSubstrateCuZnSnIntroduce H2S into chamber during sputter

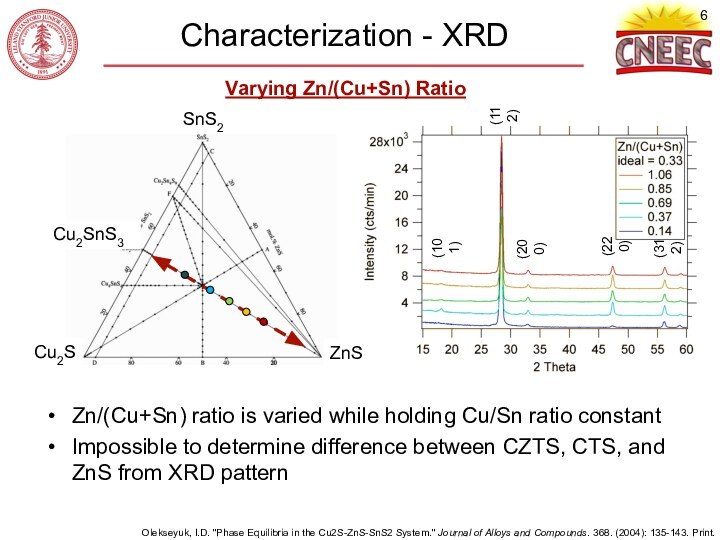

- 6. Characterization - XRDVarying Zn/(Cu+Sn) RatioZn/(Cu+Sn) ratio is

- 7. Characterization - XRDVarying Cu/(Zn+Sn) RatioCu/(Zn+Sn) ratio is

- 8. Characterization – RamanVarying Zn/(Cu+Sn) RatioRaman spectra show

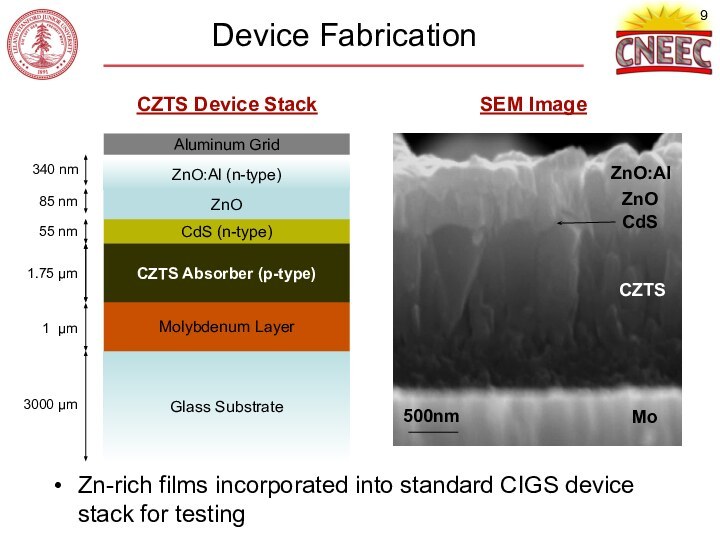

- 9. Device FabricationGlass Substrate3000 µmMolybdenum Layer1 µm1.75 µmCdS

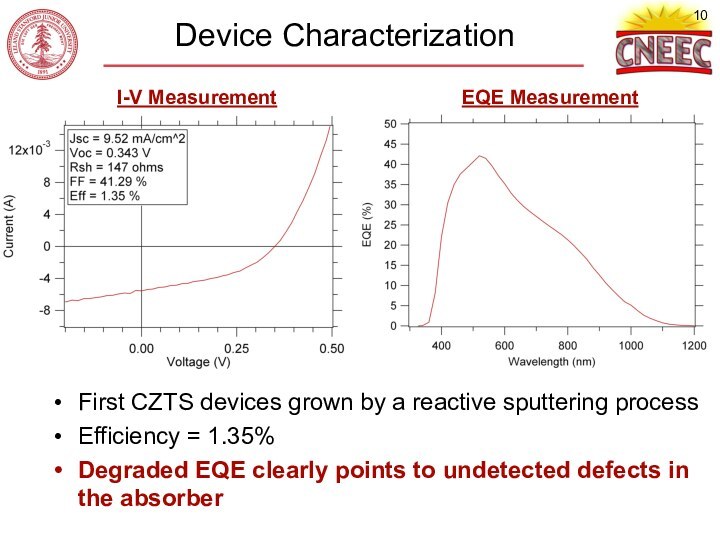

- 10. Device CharacterizationI-V MeasurementEQE MeasurementFirst CZTS devices grown

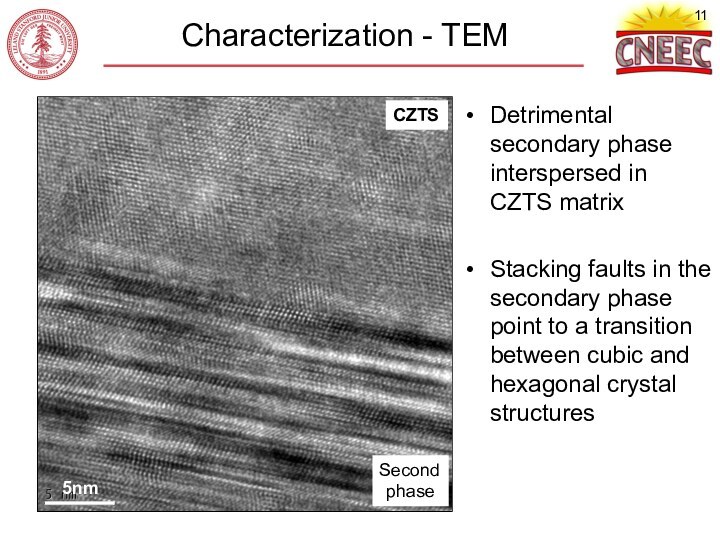

- 11. Characterization - TEM500nmDetrimental secondary phase interspersed in

- 12. Characterization - AugerRaster beam over sputtered surface

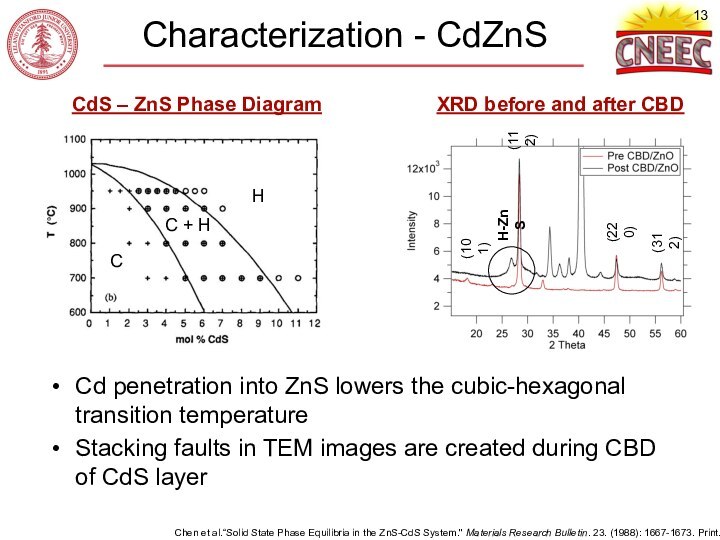

- 13. Characterization - CdZnSCd penetration into ZnS lowers

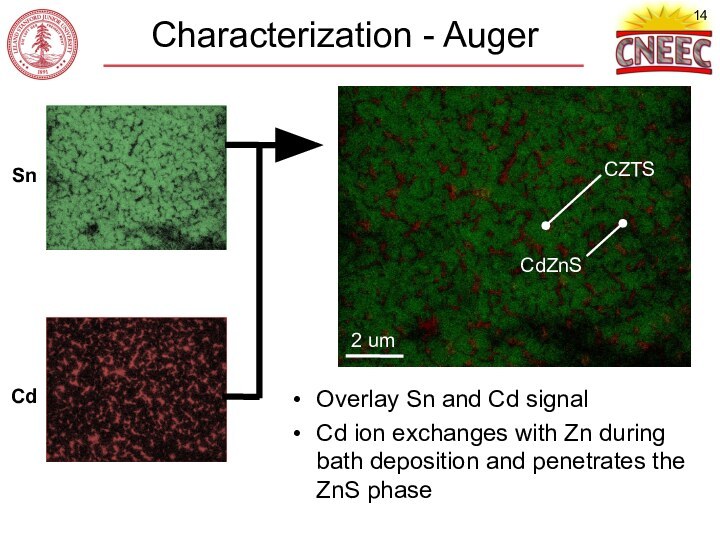

- 14. Characterization - AugerSnCdOverlay Sn and Cd signalCd

- 15. SummaryCZTS thin films were grown using Reactive

- 16. AcknowledgementsUS Department of Energy, Office of Basic

- 17. Скачать презентацию

- 18. Похожие презентации

Слайд 2

Outline

Motivation

Problems with characterization of thin films

Experimental approach

Results

X-ray diffraction

Raman

Spectroscopy

Слайд 3

Motivation – Phase Equilibrium

CZTS is a line compound

between Cu2SnS3 and ZnS

Theoretically even a 2-3% compositional variation

could lead to phase separationTernary Phase Diagram

Binary Phase Diagram

Olekseyuk, I.D. "Phase Equilibria in the Cu2S-ZnS-SnS2 System." Journal of Alloys and Compounds. 368. (2004): 135-143. Print.

CZTS

Слайд 4

Motivation – Crystal Structure

Crystal structures of secondary phases

similar to CZTS

All primary peaks overlap and hard to

separateLow intensity peaks cannot be seen easily in thin films

Theoretical XRD Patterns of CZTS, Cu2SnS3, and ZnS

Слайд 5

Experimental Approach

Substrate

Cu

Zn

Sn

Introduce H2S into chamber during sputter deposition

Sulfur

is incorporated into the film in one step (no

anneal)Expect to see higher densities and improved film quality

Reactive Sputtering

Слайд 6

Characterization - XRD

Varying Zn/(Cu+Sn) Ratio

Zn/(Cu+Sn) ratio is varied

while holding Cu/Sn ratio constant

Impossible to determine difference between

CZTS, CTS, and ZnS from XRD pattern(101)

(200)

(220)

(312)

(112)

Olekseyuk, I.D. "Phase Equilibria in the Cu2S-ZnS-SnS2 System." Journal of Alloys and Compounds. 368. (2004): 135-143. Print.

Слайд 7

Characterization - XRD

Varying Cu/(Zn+Sn) Ratio

Cu/(Zn+Sn) ratio is varied

while holding Zn/Sn ratio constant

Need to get very far

off 2:1:1 stoichiometry before any CuxS phases can be seenCuxS can be removed with KCN etch

(101)

(200)

(220)

(312)

(112)

Olekseyuk, I.D. "Phase Equilibria in the Cu2S-ZnS-SnS2 System." Journal of Alloys and Compounds. 368. (2004): 135-143. Print.

Слайд 8

Characterization – Raman

Varying Zn/(Cu+Sn) Ratio

Raman spectra show only

minor changes even though composition is varied dramatically

No evidence

of the CuxS phase shown by other groups at growth temperatures higher than 500CVarying Cu/(Zn+Sn) Ratio

Слайд 9

Device Fabrication

Glass Substrate

3000 µm

Molybdenum Layer

1 µm

1.75 µm

CdS (n-type)

55

nm

ZnO:Al (n-type)

340 nm

Aluminum Grid

CZTS Absorber (p-type)

CZTS Device Stack

Zn-rich films

incorporated into standard CIGS device stack for testingZnO

85 nm

ZnO

ZnO:Al

CdS

CZTS

Mo

SEM Image

Слайд 10

Device Characterization

I-V Measurement

EQE Measurement

First CZTS devices grown by

a reactive sputtering process

Efficiency = 1.35%

Degraded EQE clearly points

to undetected defects in the absorber

Слайд 11

Characterization - TEM

500nm

Detrimental secondary phase interspersed in CZTS

matrix

Stacking faults in the secondary phase point to a

transition between cubic and hexagonal crystal structures

Слайд 12

Characterization - Auger

Raster beam over sputtered surface of

sample and scan for Cu, Zn, Sn

Overlay Cu, Zn,

Sn signalComposition variation points to CZTS / ZnS (Zn-rich)

2 um

Cu

Zn

Sn

CZTS

ZnS

Слайд 13

Characterization - CdZnS

Cd penetration into ZnS lowers the

cubic-hexagonal transition temperature

Stacking faults in TEM images are created

during CBD of CdS layerCdS – ZnS Phase Diagram

(101)

H-ZnS

(220)

(312)

(112)

XRD before and after CBD

C

C + H

H

Chen et al.“Solid State Phase Equilibria in the ZnS-CdS System." Materials Research Bulletin. 23. (1988): 1667-1673. Print.

Слайд 14

Characterization - Auger

Sn

Cd

Overlay Sn and Cd signal

Cd ion

exchanges with Zn during bath deposition and penetrates the

ZnS phaseCZTS

CdZnS

2 um

Слайд 15

Summary

CZTS thin films were grown using Reactive Sputtering

Films

were characterized using X-ray Diffraction and Raman Spectroscopy

Full devices

have been grown and tested but are limited due to secondary phases in the filmsTransmission Electron Microscopy and Scanning Auger Microscopy can be used to identify these secondary phases

Слайд 16

Acknowledgements

US Department of Energy, Office of Basic Energy

Sciences as part of an Energy Frontier Research Center

http://www.er.doe.gov/bes/EFRC/index.html

Applied

Quantum TechnologiesLocal thin film solar startup

http://www.aqtsolar.com