Слайд 2

Drilling Fluid Function

Drilling Fluid Function

1.Transport cutting and dispose

to surface - The drilling fluid brings the drilled

material to the ground surface

either by mud rheology and velocity

Слайд 3

Drilling Fluid Function

2. Clean drill bits – As

drilling fluid exits the bit jets, fluid velocity removes

cutting from the bit teeth and bit body.

This prevents bit

ball up situation.

Слайд 4

Drilling Fluid Function

3. Provide hydrostatic pressure to control

well while drilling –Hydrostatic pressure provided from drilling fluid

is the primary well control. Mud weight should be high enough

to control formation pressure while drilling.

P=0.052*MW*TVD

Psi=0.052*ppg*ft

Слайд 5

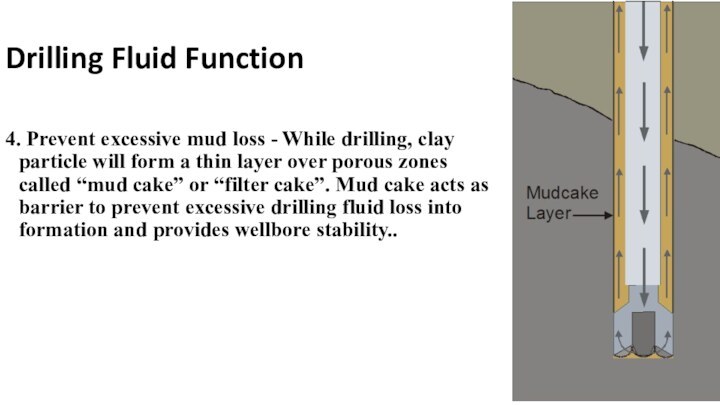

Drilling Fluid Function

4. Prevent excessive mud loss -

While drilling, clay particle will form a thin layer

over porous zones called “mud cake” or “filter cake”. Mud cake acts as barrier to prevent excessive drilling fluid loss into formation and provides wellbore stability..

Слайд 6

Drilling Fluid Function

5. Prevent formation damage by using

reservoir drill-in fluid – While drilling long reach zone

in horizontal wells, the special drilling fluid will be utilized in order to prevent formation damage.

Слайд 7

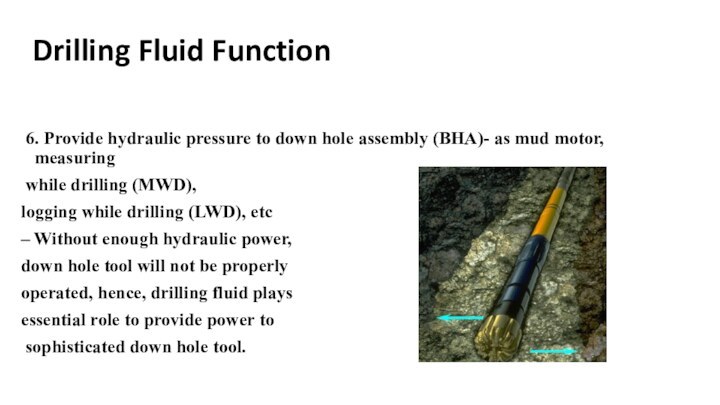

Drilling Fluid Function

6. Provide hydraulic pressure to

down hole assembly (BHA)- as mud motor, measuring

while

drilling (MWD),

logging while drilling (LWD), etc

– Without enough hydraulic power,

down hole tool will not be properly

operated, hence, drilling fluid plays

essential role to provide power to

sophisticated down hole tool.

Слайд 8

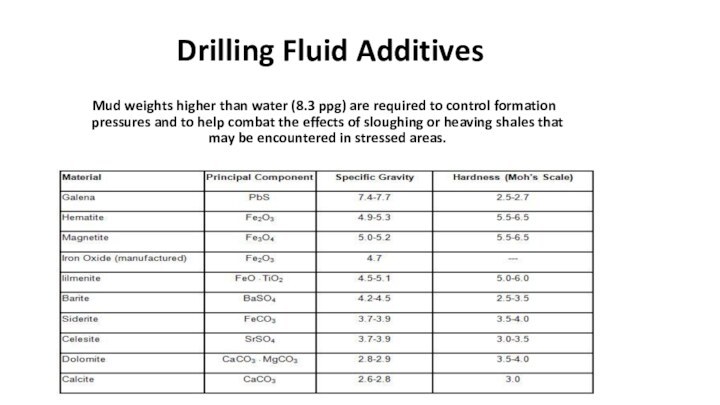

Drilling Fluid Additives

There are many drilling fluid additives

which are used to either change the mudweight(density) or

change its chemical properties .

1.Weighting Materials:

Weighting materials (densifiers) are compounds that are dissolved or suspended in drilling fluid to increase its density. They are used to control formation pressures and to help combat the effects of sloughing or heaving shales that may be encountered in stressed areas.

Any substance that is denser than water and that does not adversely

affect other properties of the drilling fluid can

be used as a weighting material

Слайд 9

Drilling Fluid Additives

Mud weights higher than water

(8.3 ppg) are required to control formation pressures and

to help combat the effects of sloughing or heaving shales that may be encountered in stressed areas.

Слайд 11

Air drilling

Advantages:

Higher penetration rates

Better hole cleaning

Less formation damage

Disadvantages:

Air

cannot support the wellbore stability

Doesn’t provide enough pressure

Слайд 12

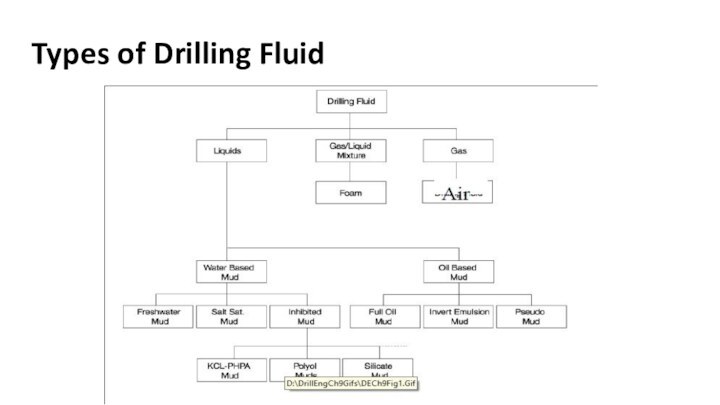

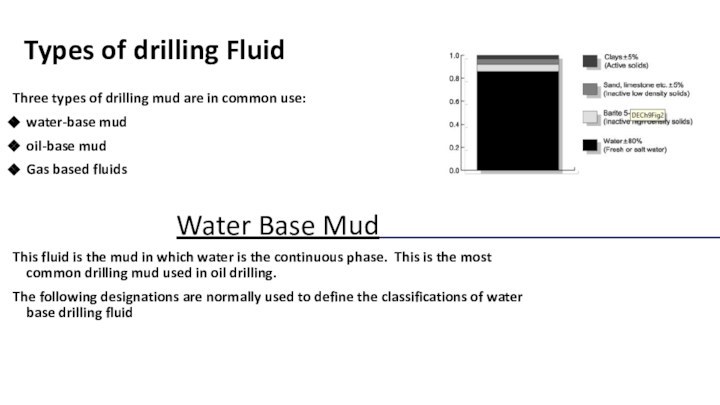

Types of drilling Fluid

Three types of drilling mud

are in common use:

water-base mud

oil-base mud

Gas based fluids

Water

Base Mud

This fluid is the mud in which water is the continuous phase. This is the most common drilling mud used in oil drilling.

The following designations are normally used to define the classifications of water base drilling fluid

Слайд 13

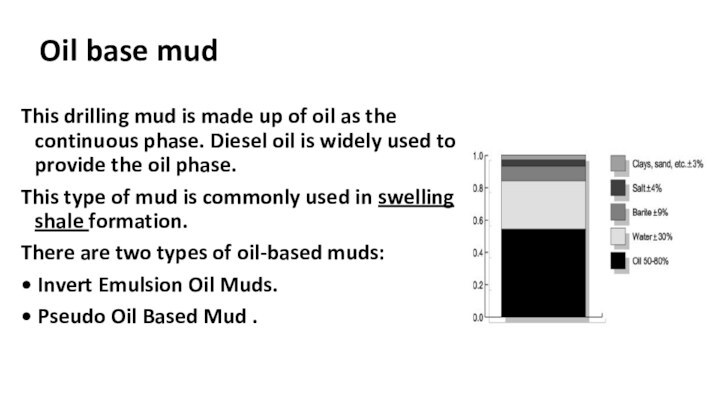

Oil base mud

This drilling mud is made up

of oil as the continuous phase. Diesel oil is

widely used to provide the oil phase.

This type of mud is commonly used in swelling shale formation.

There are two types of oil-based muds:

• Invert Emulsion Oil Muds.

• Pseudo Oil Based Mud .

Слайд 14

Advantages of Oil Based Mud

• The oil base

mud is good for high temperature environment because the

base fluid is oil.

• It is good for drilling into shale formation because it does not react with formation clay causing shale instability.

• It typically creates thin mud cake. This is really good because you can reduce risk for pipe stuck situation.

• It can be treated and reused. Using this mud for long run can reduce overall drilling mud cost.

• Oil base as external phase is good lubricant so it greatly reduce drilling torque.

Слайд 15

Disadvantages of OBM

Environmental concern – Oil base mud

is considered as toxic waste therefore it cannot be

disposed directly into land, river, or ocean

People Heath – This mud has hazardous vapors which will cause health problem to personnel who working with it in both short and long term.

Cost – Mud cost of this system is higher than water base mud in terms of cost per barrel.

Gas kick detection – Gas kick is very difficult to identify because gas is soluble in oil. You may take kick but you will be able to see pit gain or flow increase at the first time.

Equipment – Rubber parts is easily deteriorated by oil base.

Слайд 16

Density

((Any accepted terminology that indicates the weight

per unit volume of drilling fluid))

-Pounds per gallon (ppg).

-Pounds

per cubic feet (pcf).

-Gram per cubic centimeter (g/cc).

-Kilogram per liter (kg/l).

Слайд 17

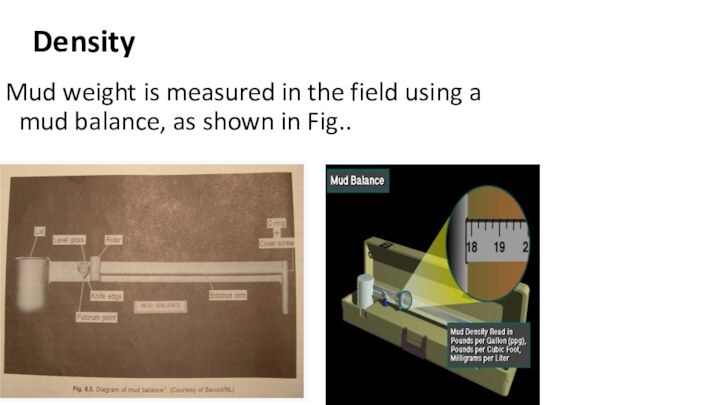

Density

Mud weight is measured in the field

using a mud balance, as shown in Fig..

Слайд 18

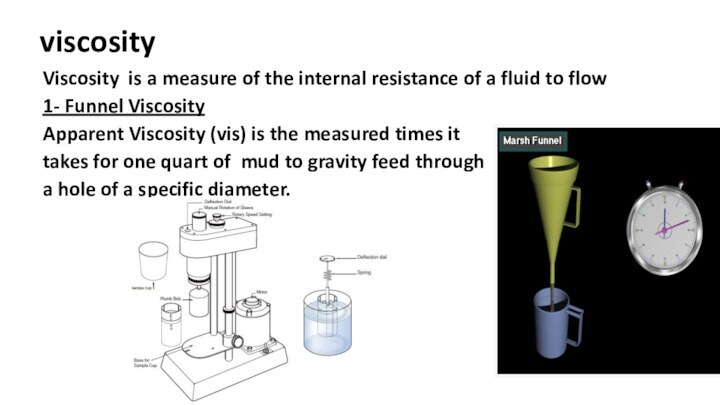

viscosity

Viscosity is a measure of the internal

resistance of a fluid to flow

1- Funnel Viscosity

Apparent Viscosity

(vis) is the measured times it

takes for one quart of mud to gravity feed through

a hole of a specific diameter.

Слайд 19

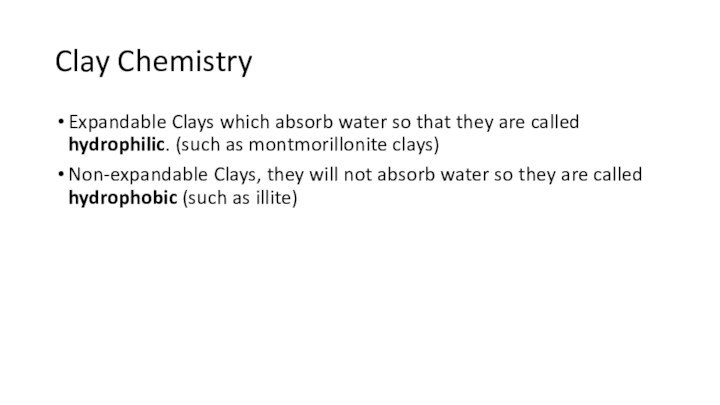

Clay Chemistry

Expandable Clays which absorb water so that

they are called hydrophilic. (such as montmorillonite clays)

Non-expandable Clays,

they will not absorb water so they are called hydrophobic (such as illite)

Слайд 20

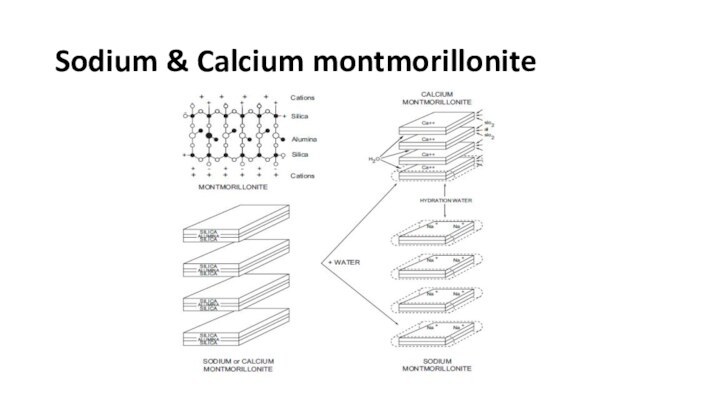

Sodium & Calcium montmorillonite

Слайд 21

Viscosity Control additives to WBM

Native clays

Wyoming Bentonite

To reduce

the viscosity of the mud:

Reduce the solids content

Reduce the

number of particles per unit volume

Neutralize the attractive forces between the particles. (Using thinners)