- Главная

- Разное

- Бизнес и предпринимательство

- Образование

- Развлечения

- Государство

- Спорт

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Религиоведение

- Черчение

- Физкультура

- ИЗО

- Психология

- Социология

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Что такое findslide.org?

FindSlide.org - это сайт презентаций, докладов, шаблонов в формате PowerPoint.

Обратная связь

Email: Нажмите что бы посмотреть

Презентация на тему Kinetics melting and electrode metal transfer features in electric-arc welding flux cord wire in shielding gases

Содержание

- 2. The purpose of the researchResearching the features

- 3. Relevance of the workNowadays, there is an

- 4. Research complex 1 – personal computer; 2

- 5. PDG-201 «NEON» Research complex equipmentDigital recorder of welding parameters AWR-224МДDigital high-speed camera «Baumer»FEB-315 «MAGMA»

- 6. Principle of the research complexBefore running the

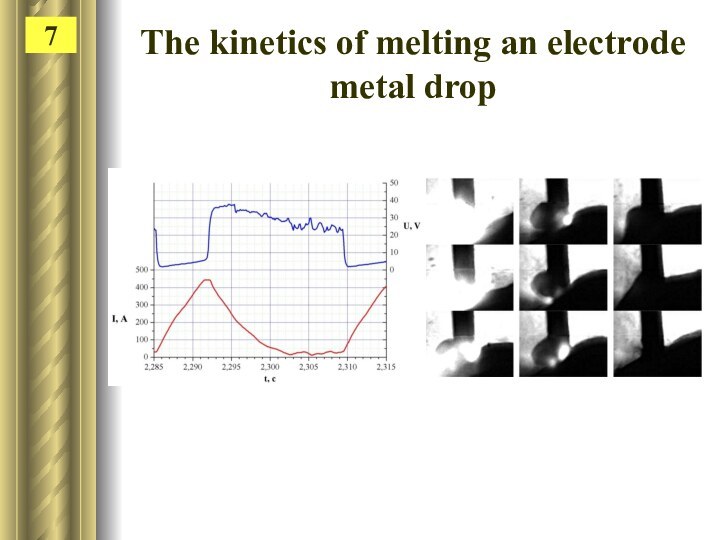

- 7. The kinetics of melting an electrode metal drop

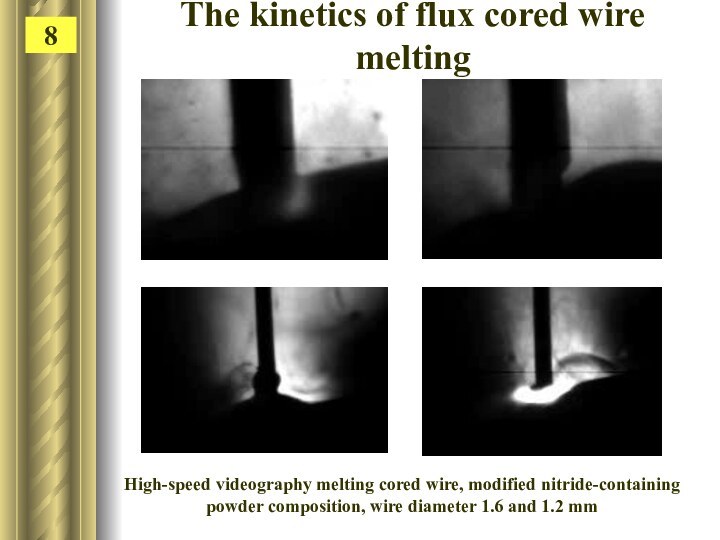

- 8. High-speed videography melting cored wire, modified nitride-containing

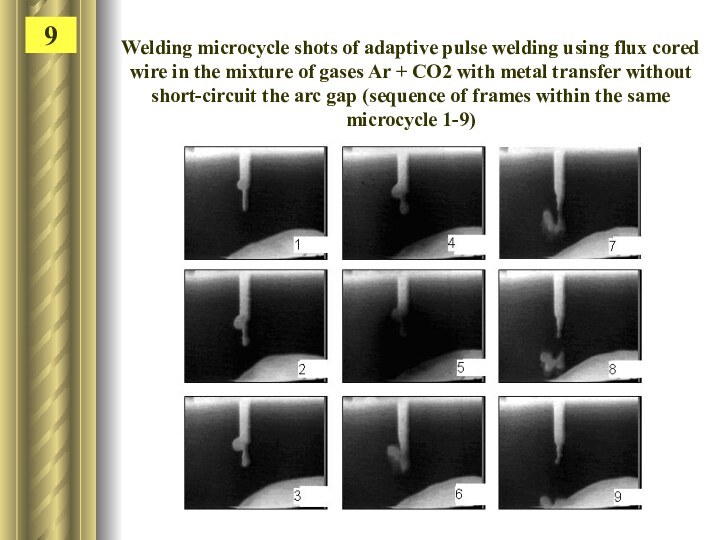

- 9. Welding microcycle shots of adaptive pulse

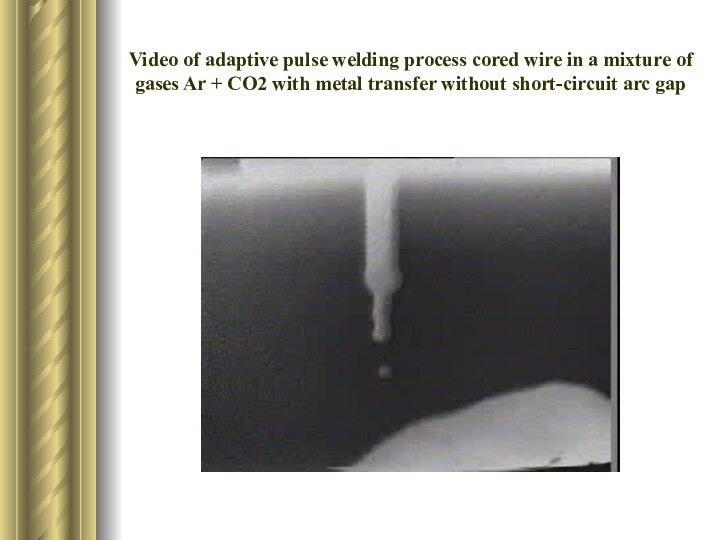

- 10. Video of adaptive pulse welding process cored

- 11. CONCLUSION The executed researches on studying of

- 12. CONCLUSIONResearches of the fast-proceeding processes of melting

- 13. Скачать презентацию

- 14. Похожие презентации

The purpose of the researchResearching the features of melting and electrode metal transfer to the weld pool using high-speed video for welding and surfacing flux cored wire.

Слайд 3

Relevance of the work

Nowadays, there is an active

development of welding flux-cored wires. Develop new designs and

compositions of filler wires. It is possible that in the future, welding cored wires will lead in production, because this method is easy to use, less time consuming, and also has a higher technological opportunities. Researching the features of melting and electrode metal transfer using cored wires for welding will determine the best modes for welding and surfacing, improve the quality of welding, that enhances result of adopting this method of welding in many branches of engineering.

Слайд 4

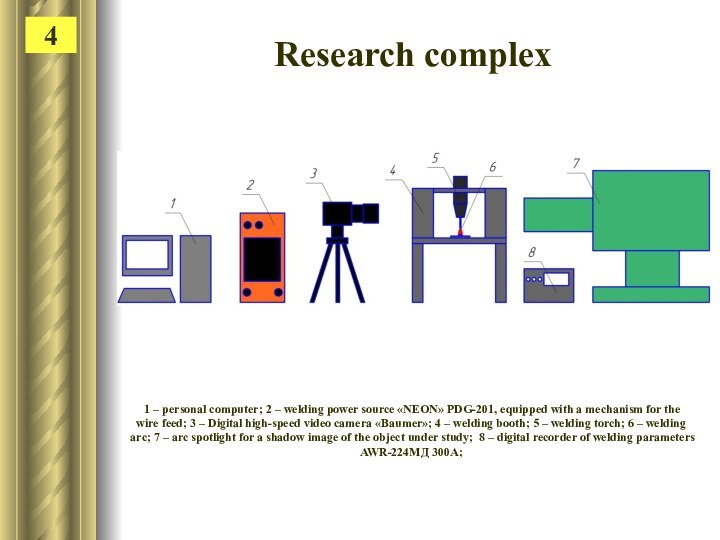

Research complex

1 – personal computer; 2 –

welding power source «NEON» PDG-201, equipped with a mechanism

for the wire feed; 3 – Digital high-speed video camera «Baumer»; 4 – welding booth; 5 – welding torch; 6 – welding arc; 7 – arc spotlight for a shadow image of the object under study; 8 – digital recorder of welding parameters AWR-224МД 300А;

Слайд 5

PDG-201 «NEON»

Research complex equipment

Digital recorder of welding

parameters AWR-224МД

Digital high-speed camera «Baumer»

FEB-315 «MAGMA»

Слайд 6

Principle of the research complex

Before running the complex

held pre-focus projector at the welding arc, as well

as focus digital video camera.The launch complex is carried out in the following order:

Includes a power source arc and an additional light source when idling.

Turns DVR settings, a computer and a digital camera in the standby mode.

Set up the necessary welding parameters and video recording options (using special software installed on a computer).

Raised arc.

During the welding process is carried out using the registration parameters recorder of welding parameters. After the termination of the process of registering, terminate power supply to the welding arc.

Then going the image processing and processing welding parameters on computer. After processing, the video file is saved, change the parameters of the welding then the process is repeated.