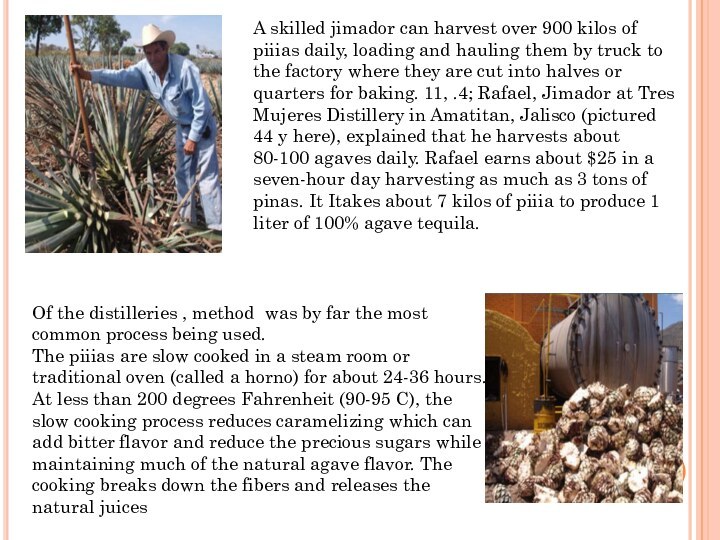

of piiias daily, loading and hauling them by truck

to the factory where they are cut into halves or quarters for baking. 11, .4; Rafael, Jimador at Tres Mujeres Distillery in Amatitan, Jalisco (pictured44 y here), explained that he harvests about 80-100 agaves daily. Rafael earns about $25 in a seven-hour day harvesting as much as 3 tons of pinas. It Itakes about 7 kilos of piiia to produce 1 liter of 100% agave tequila.

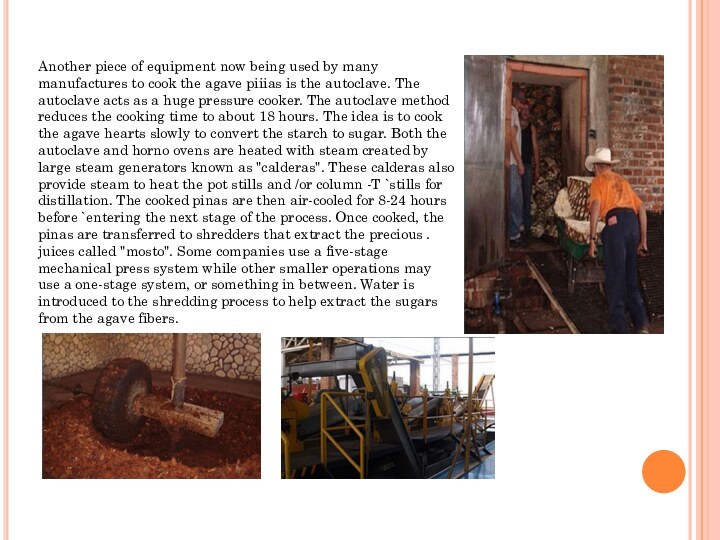

Of the distilleries , method was by far the most common process being used.

The piiias are slow cooked in a steam room or traditional oven (called a horno) for about 24-36 hours. At less than 200 degrees Fahrenheit (90-95 C), the slow cooking process reduces caramelizing which can add bitter flavor and reduce the precious sugars while maintaining much of the natural agave flavor. The cooking breaks down the fibers and releases the natural juices