- Главная

- Разное

- Бизнес и предпринимательство

- Образование

- Развлечения

- Государство

- Спорт

- Графика

- Культурология

- Еда и кулинария

- Лингвистика

- Религиоведение

- Черчение

- Физкультура

- ИЗО

- Психология

- Социология

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Маркетинг

- Математика

- Медицина

- Менеджмент

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, картинки для презентаций

- Экология

- Экономика

- Юриспруденция

Что такое findslide.org?

FindSlide.org - это сайт презентаций, докладов, шаблонов в формате PowerPoint.

Обратная связь

Email: Нажмите что бы посмотреть

Презентация на тему Steel production

Содержание

- 2. Steel productionSteel production is an important step

- 3. methods for the melting of steelbasic oxygen processopen-hearth processelectric-furnace process

- 4. Pouring is a critical step in steel production

- 5. basic oxygen process The furnaces used in

- 6. open-hearth process The use of oxygen, natural

- 7. The second half of the 20th century

- 8. A development in steel production of great

- 9. The mid-1960’s witnessed the beginning of an intensive development of electrometallurgical processesArc furnacesInduction furnaces

- 10. With regard to pouring, there has been

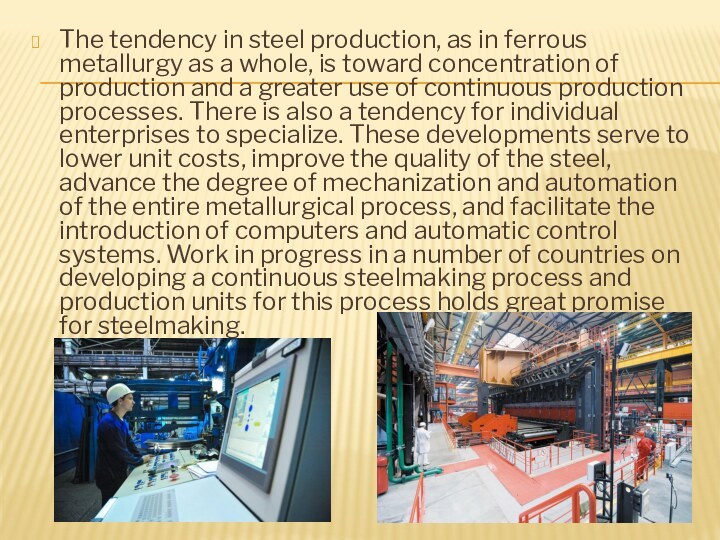

- 11. The tendency in steel production, as in

- 12. Скачать презентацию

- 13. Похожие презентации

Steel productionSteel production is an important step in the overall production cycle of ferrous metallurgy, the others being the production of pig iron in blast furnaces and the rolling of steel ingots and semifinished shapes. The