Business Philosophy

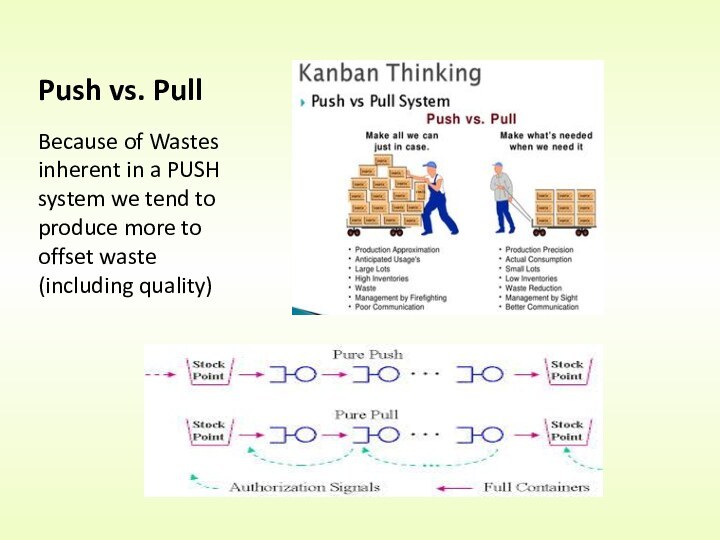

Production system: manufacturing & movement of materials and

goods occur just when they are needed, usually in small batchesJIT operates with very little “fat” (waste)

Defines waste in terms of customer value

JIT Goals

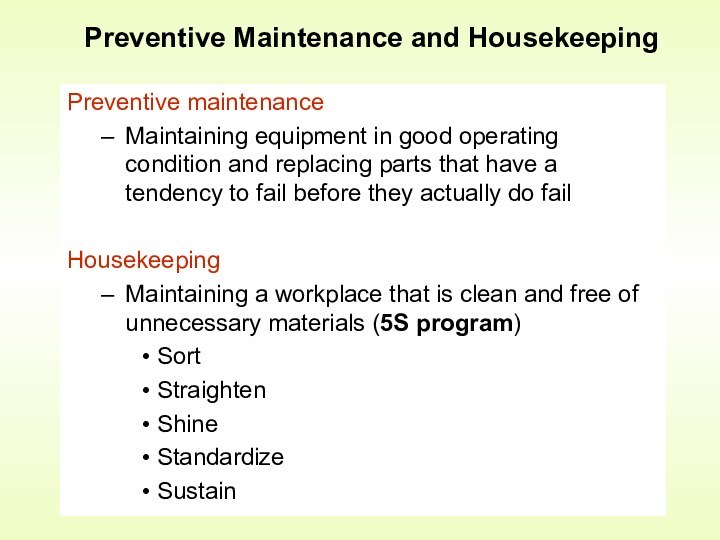

Eliminate disruptions

Make system flexible by reduce setup and lead times

Eliminate waste, especially excess inventory