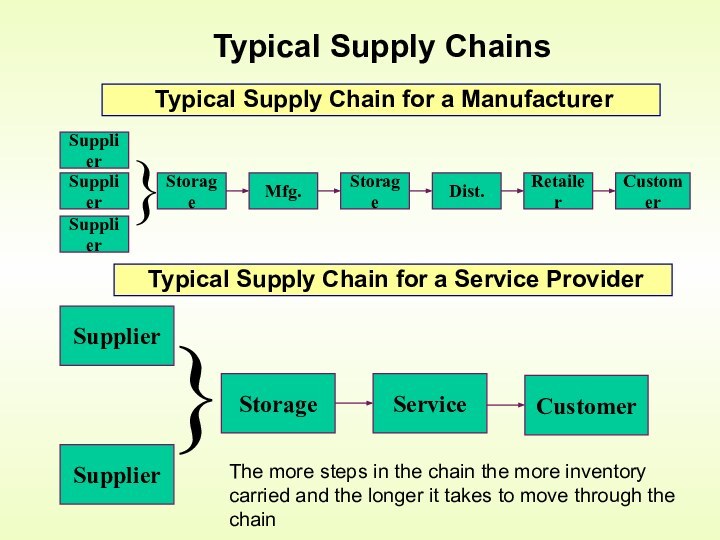

activities, that are involved in producing and delivering a

product or service to anywhere in the worldTypical Facilities:

Warehouses, Factories, Distribution Centers, Wholesalers, Resellers, Retail outlets

FindSlide.org - это сайт презентаций, докладов, шаблонов в формате PowerPoint.

Email: Нажмите что бы посмотреть

Need for Supply Chain Management

Outsourcing: Buying goods or services instead of producing or providing them in house

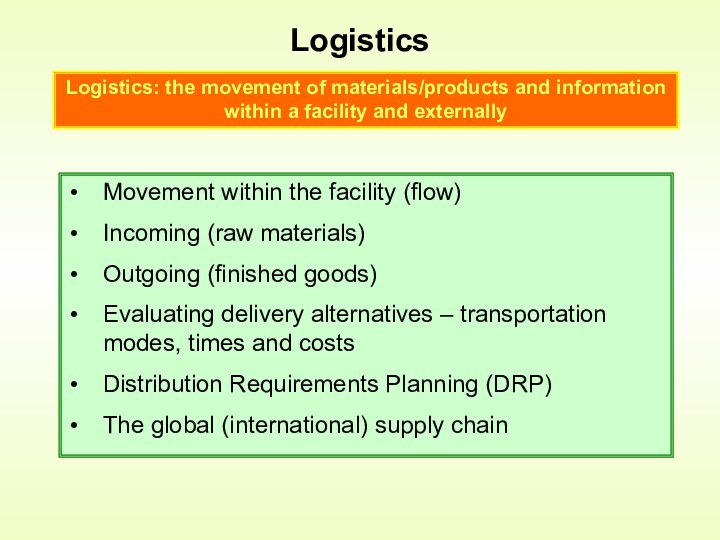

Logistics: the movement of materials/products and information within a facility and externally

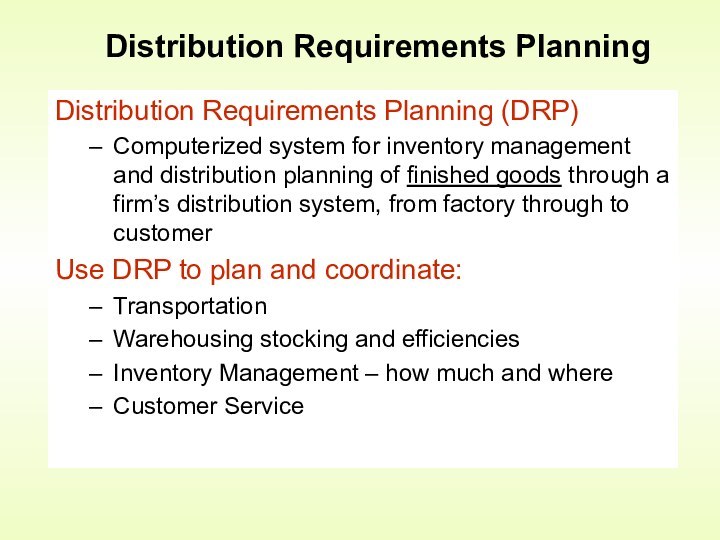

Distribution Requirements Planning

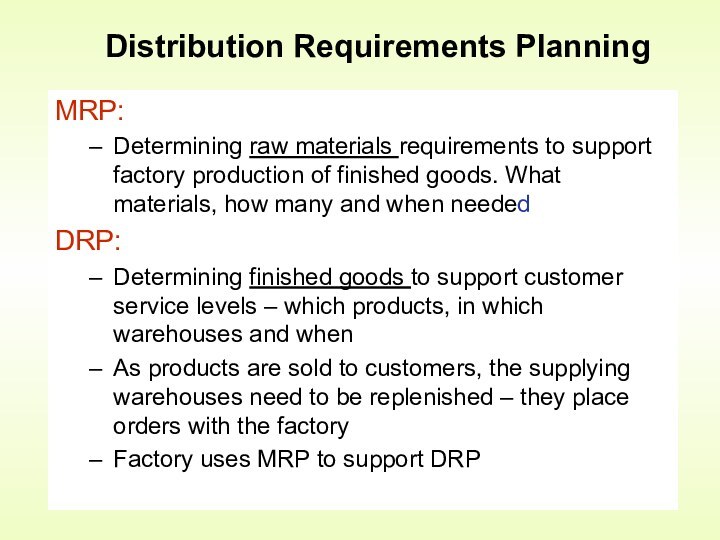

Distribution Requirements Planning

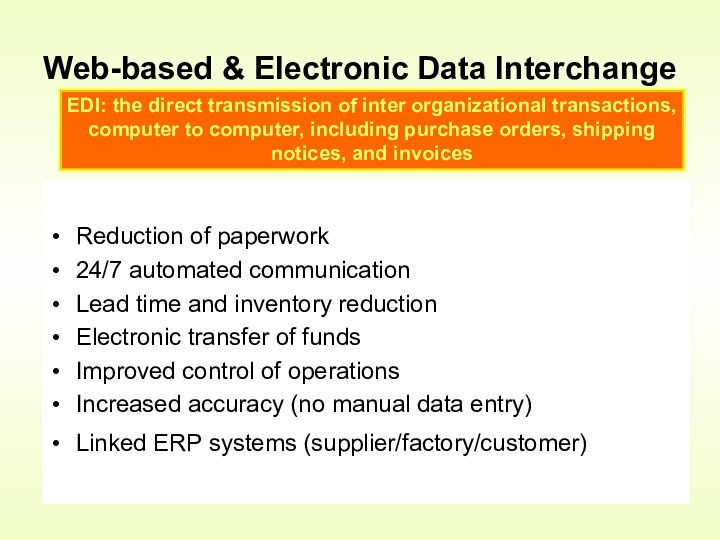

Web-based & Electronic Data Interchange

EDI: the direct transmission of inter organizational transactions, computer to computer, including purchase orders, shipping notices, and invoices

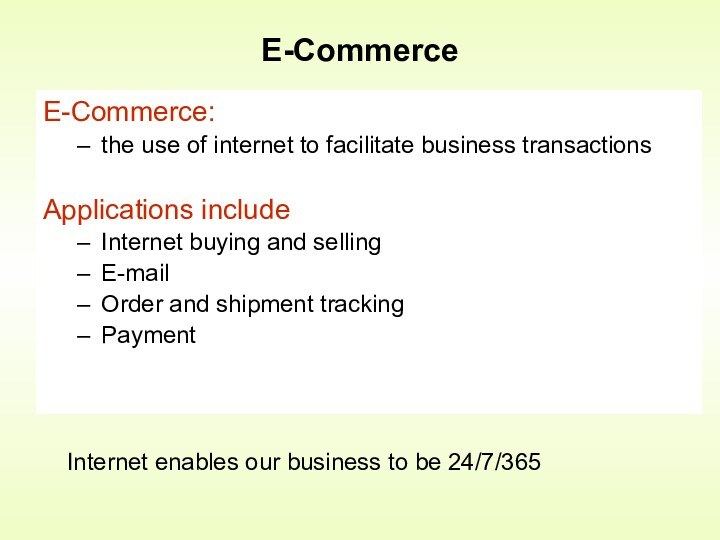

Advantages of E-Commerce

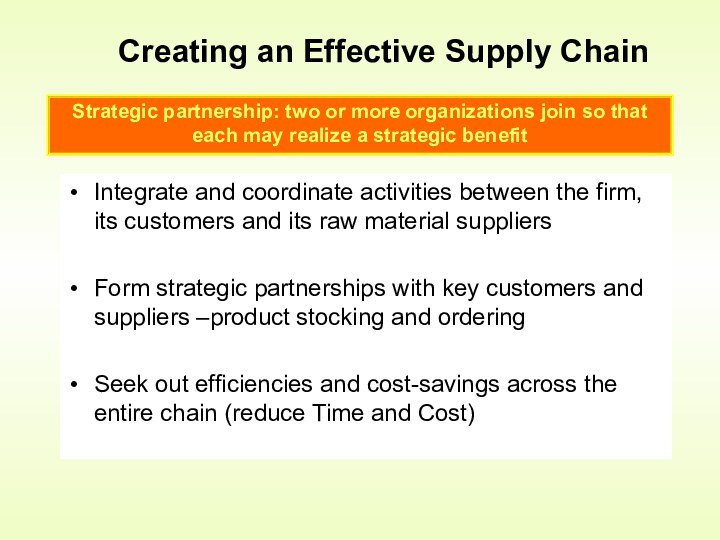

Creating an Effective Supply Chain

Strategic partnership: two or more organizations join so that each may realize a strategic benefit

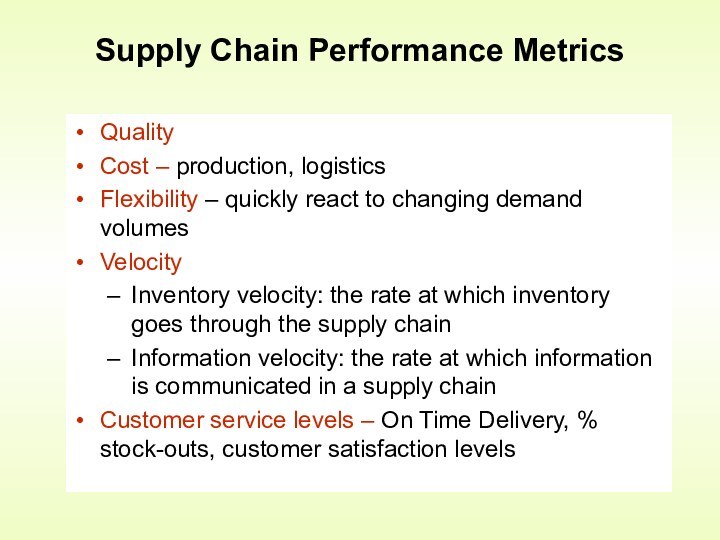

Supply Chain Performance Metrics

Purchasing

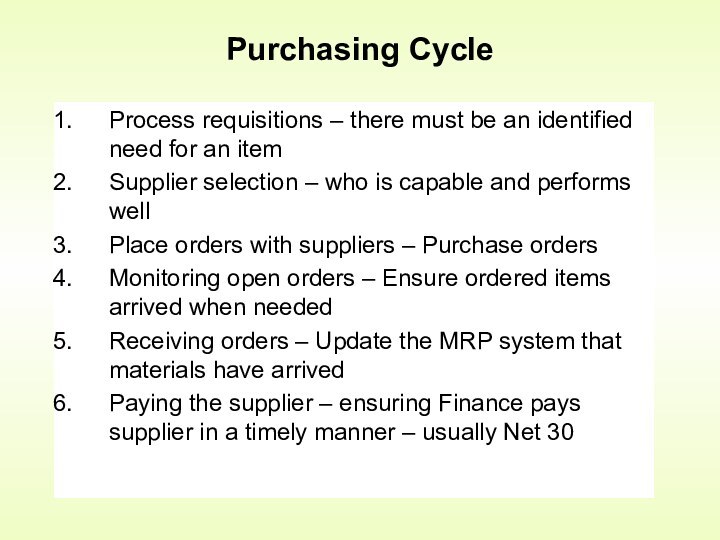

Purchasing Cycle

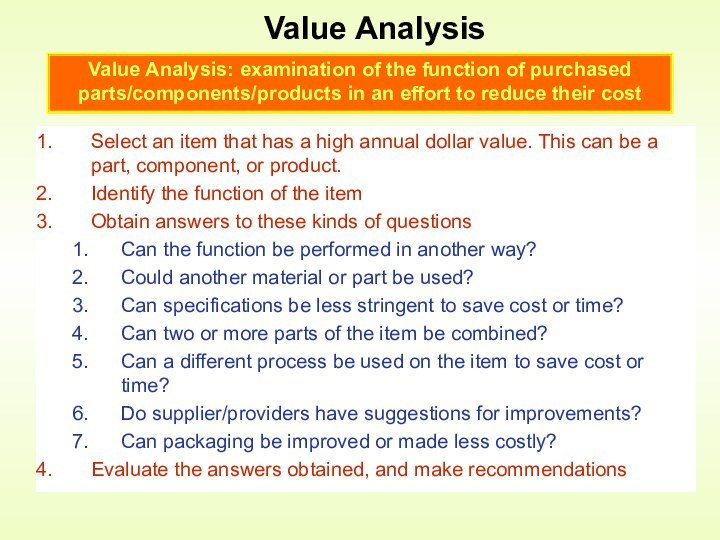

Select an item that has a high annual dollar value. This can be a part, component, or product.

Identify the function of the item

Obtain answers to these kinds of questions

Can the function be performed in another way?

Could another material or part be used?

Can specifications be less stringent to save cost or time?

Can two or more parts of the item be combined?

Can a different process be used on the item to save cost or time?

Do supplier/providers have suggestions for improvements?

Can packaging be improved or made less costly?

Evaluate the answers obtained, and make recommendations

Make or Buy

Determining Prices